Coaxiality detection and regulation method

An adjustment method and coaxiality measurement technology, which is applied in the field of processing and assembly, can solve the problems of inability to quantify accurate adjustment, high labor intensity, and high rework rate, and achieve the effects of improving assembly quality, reducing workpiece rework rate, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

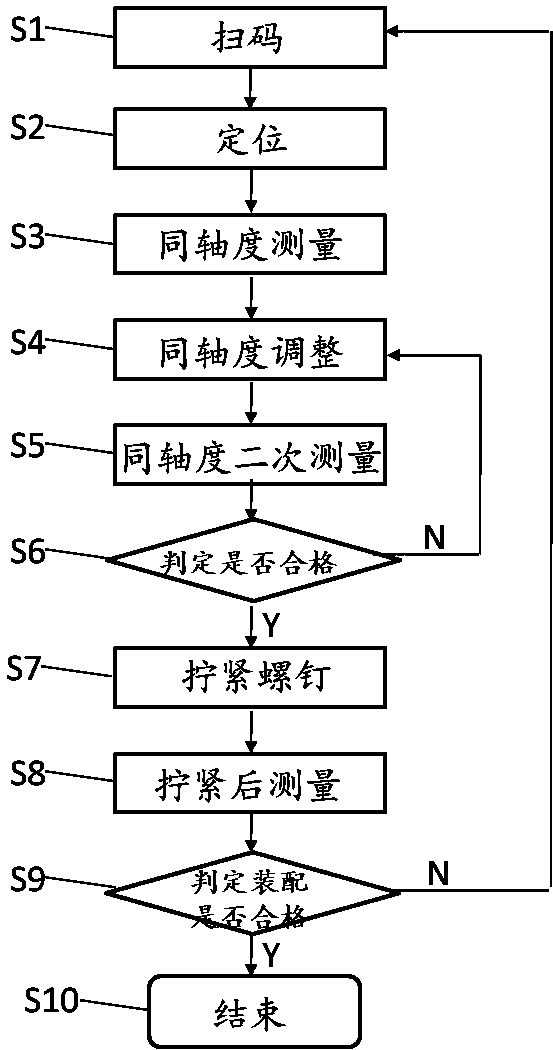

Method used

Image

Examples

Embodiment 1

[0078] In the following, the hole diameter of No. 1 assembly hole in a circular workpiece is Φ1.7, and the outer circle of No. Ⅱ in a cylindrical workpiece is Φ65 for example.

[0079] (ⅰ) Scan code

[0080] Use a code scanner to scan the QR code of the cylindrical part and record the assembly information of the assembly.

[0081] (ii) Positioning

[0082] Put the cylindrical part into the positioning tool, and the positioning tool will automatically clamp the cylindrical part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com