Conductive film and metal grid touch sensor

A touch sensor, metal grid technology, applied in the direction of instrument, electrical digital data processing, data processing input/output process, etc., can solve the problems of large charging of conductive wire, low signal lift, weak signal, etc. Control signal stability, increase touch sensitivity and accuracy, and reduce the effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

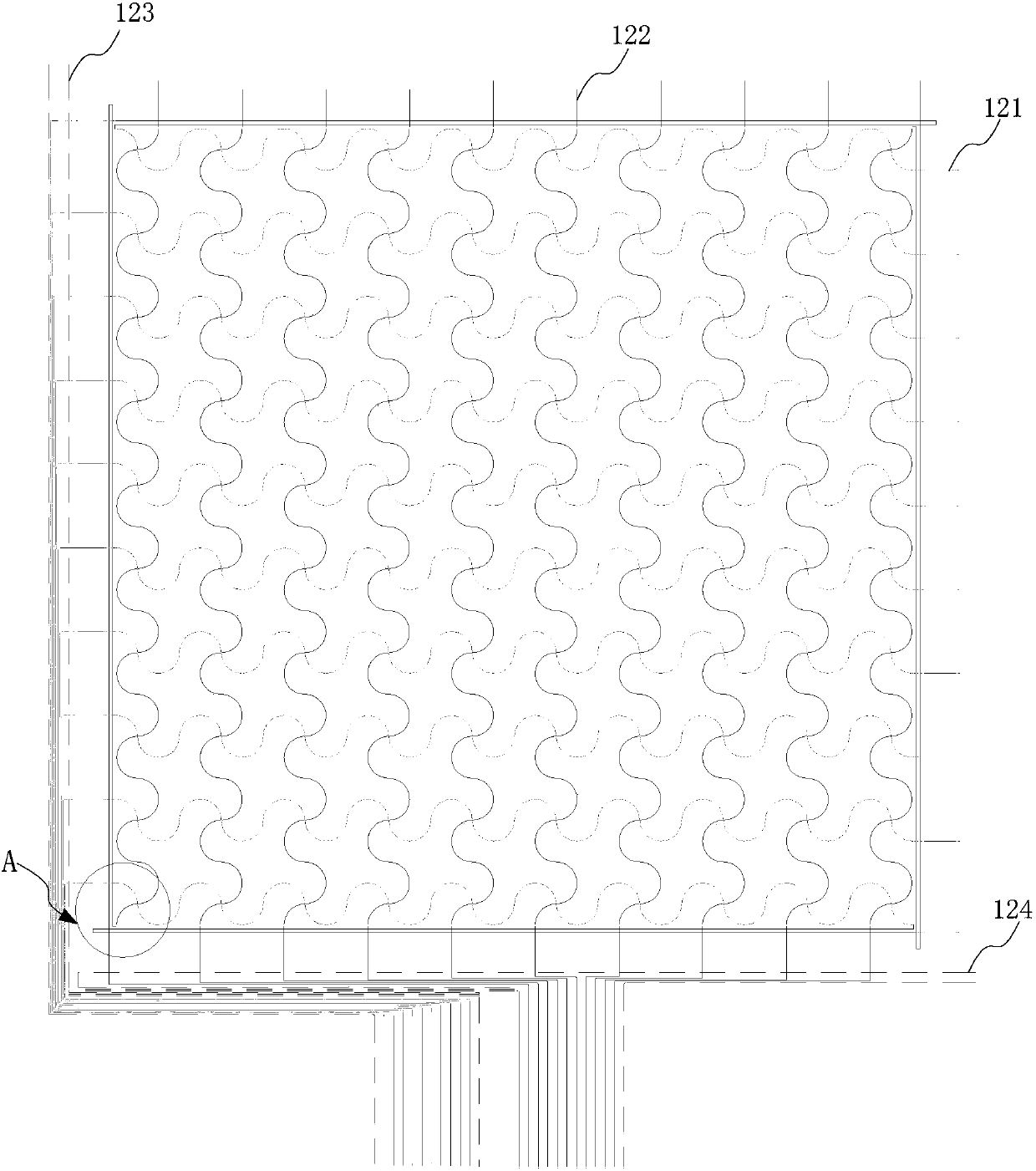

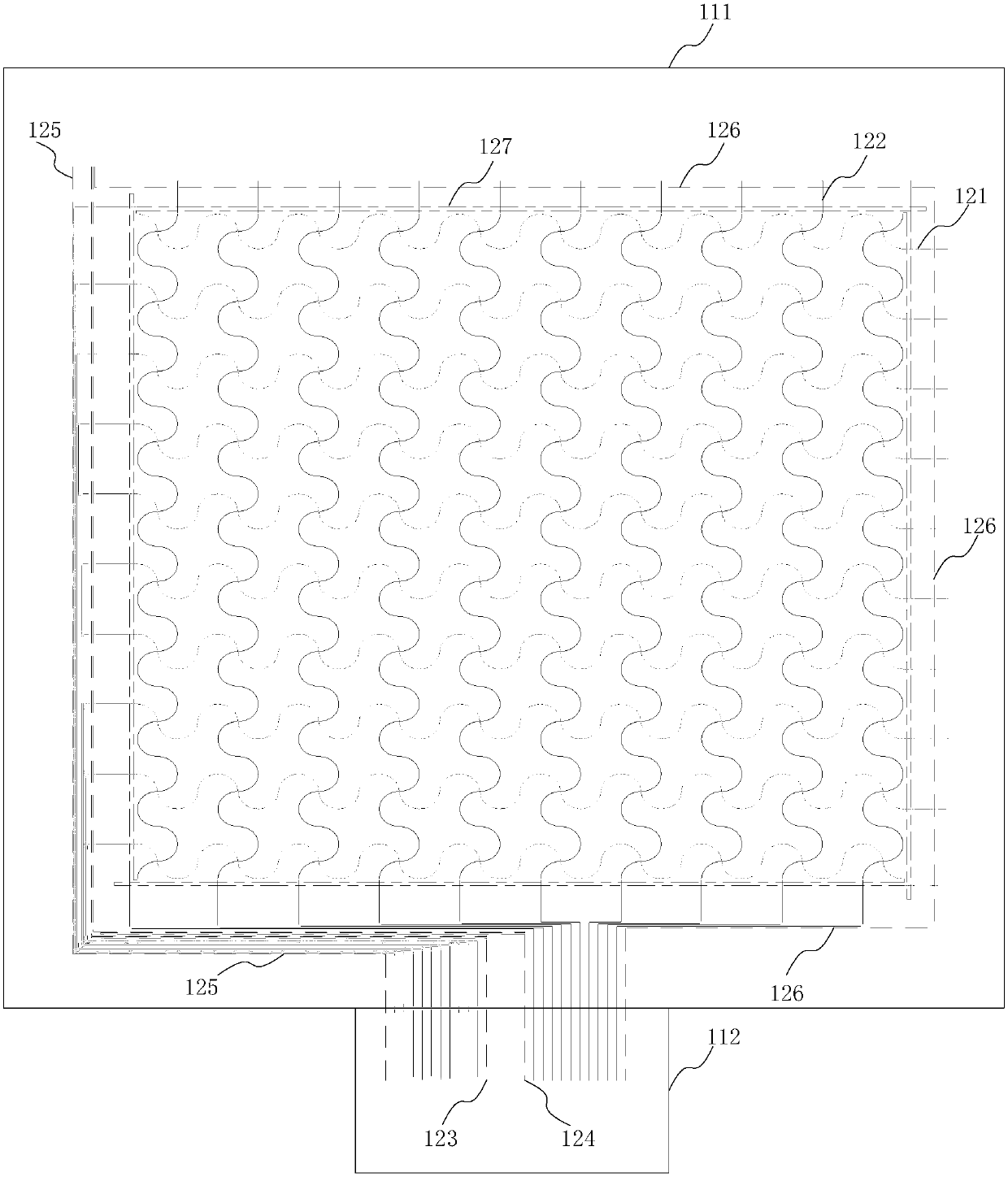

[0045] This embodiment discloses a conductive film 100 based on Metal-Mesh technology, such as figure 2 and image 3 As shown, a substrate 110 and a conductive layer 120 are included. Also, the shape of the conductive film 100 is a rectangle.

[0046] The substrate 110 may be a transparent substrate or an opaque substrate. Specifically in this embodiment, the conductive film 100 is applied to a super-sized touch screen, and the substrate 110 is a transparent substrate. The transparent substrate may be a glass plate, polycarbonate (PC), polyethylene terephthalate (polyethylene terephthalate, PET) and the like. When the conductive film of this embodiment is applied to a keypad or a touch panel of a notebook computer, the substrate may also be an opaque substrate.

[0047] Further, the substrate 110 includes a substrate main body 111 and a flexible connection part 112 ( figure 2 Not identified in the image 3 identified in ). The flexible connecting portion 112 is formed...

Embodiment 2

[0059] The structure of the conductive film 100 of this embodiment is basically the same as that of Embodiment 1, including a first conductive thread 121, a second conductive thread 123, a first isolated conductive thread 123, a second isolated conductive thread 124, a third isolated conductive thread 125, The fourth isolated conductive thread 126 and the edge conductive thread 127; wherein, a plurality of first conductive threads 121 and a plurality of second conductive threads 123 are laid crosswise in the touch area; the edge conductive thread 127 is laid along the surrounding edges of the touch area , to increase the edge touch effect; and, the first isolated conductive wire 123, the second isolated conductive wire 124, the third isolated conductive wire 125, the fourth isolated conductive wire 126 and the edge conductive wire 127 are all laid on the edge routing area. A first conductive wire 121 and a plurality of second conductive wires 123 are gathered in the edge routin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com