Whole wheat noodle improver, whole wheat noodle and preparation method thereof

A noodle improver and whole-wheat flour technology, which is applied in the direction of food ingredients as taste improvers, food science, food ingredients as color, etc., can solve the problems of production cost reduction, poor improvement of whole-wheat noodle texture quality, and product cost. Increase and other issues to achieve the effect of improving the color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

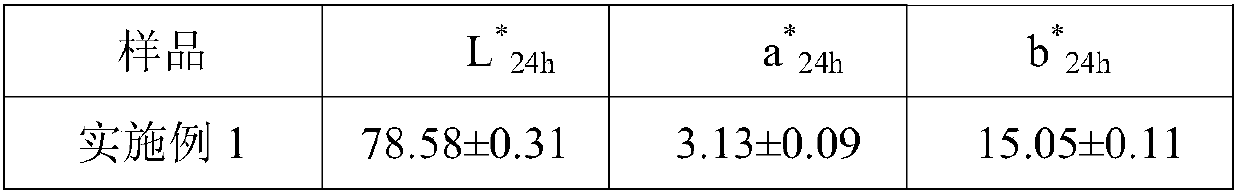

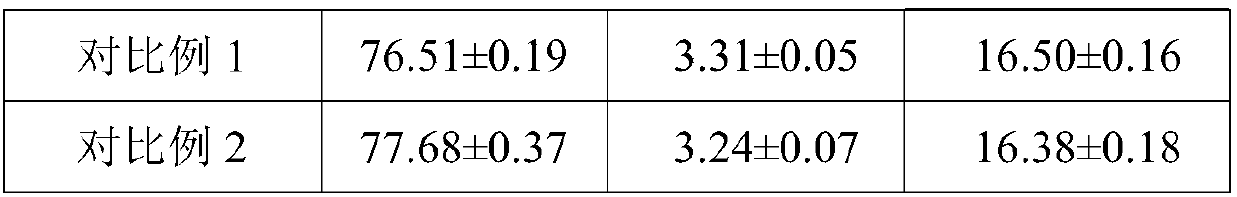

Embodiment 1

[0024] A whole-wheat noodle improver, which is composed of trisodium phosphate and sodium tripolyphosphate in a ratio of 1:3.

[0025] A kind of whole-wheat noodles, the whole-wheat noodle improver of this embodiment is added and used in the preparation process; wherein the addition amount of the whole-wheat noodle improver relative to the whole-wheat flour is: the amount of the whole-wheat noodle improver added per 100g of whole-wheat flour is 0.3g.

[0026] In the preparation process of whole wheat noodles in this embodiment, edible salt is also added, and the amount of edible salt is 1.0 g of edible salt per 100 g of whole wheat flour.

[0027] The preparation method of above-mentioned whole wheat noodles, concrete operation steps are:

[0028] 1) Preparation of whole-wheat flour: first grind and crush the whole wheat grains to obtain coarse-grained flour, then continue to grind with a superfine pulverizer, and obtain whole-wheat flour after all the powder grains pass thro...

Embodiment 2

[0031] A whole-wheat noodle improver, which is composed of trisodium phosphate and sodium tripolyphosphate in a ratio of 1:3.2.

[0032] A kind of whole-wheat noodles, the whole-wheat noodle improver of this embodiment is added and used in the preparation process; wherein the addition amount of the whole-wheat noodle improver relative to the whole-wheat flour is: the amount of the whole-wheat noodle improver added per 100g of whole-wheat flour is 0.4g.

[0033] In the preparation process of whole wheat noodles in this embodiment, edible salt is also added, and the amount of edible salt is 1.2 g for every 100 g of whole wheat flour.

[0034] The preparation method of above-mentioned whole wheat noodles, concrete operation steps are:

[0035] 1) Preparation of whole-wheat flour: first grind and crush the whole wheat grains to obtain coarse-grained flour, then continue to grind with a superfine pulverizer, and obtain whole-wheat flour after all the powder grains pass through a 1...

Embodiment 3

[0038] A whole-wheat noodle improver, which is composed of trisodium phosphate and sodium tripolyphosphate in a ratio of 1:3.5.

[0039] A kind of whole-wheat noodles, the whole-wheat noodle improver of this embodiment is added and used in the preparation process; wherein the addition amount of the whole-wheat noodle improver relative to the whole-wheat flour is: the amount of the whole-wheat noodle improver added per 100g of whole-wheat flour is 0.5g.

[0040] In the preparation process of whole wheat noodles in this embodiment, edible salt is also added, and the amount of edible salt is 1.5 g of edible salt per 100 g of whole wheat flour.

[0041] The preparation method of above-mentioned whole wheat noodles, concrete operation steps are:

[0042] 1) Preparation of whole-wheat flour: first grind and crush the whole wheat grains to obtain coarse-grained flour, then continue to grind with a superfine pulverizer, and obtain whole-wheat flour after all the powder grains pass th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com