3D printing and production system and method for garments

A 3D printing and production system technology, applied in the field of clothing production, can solve problems such as reduced comfort, long production cycle, and inaccurate sizes, and achieve the effects of reducing errors, low scrap rate, and improving size fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

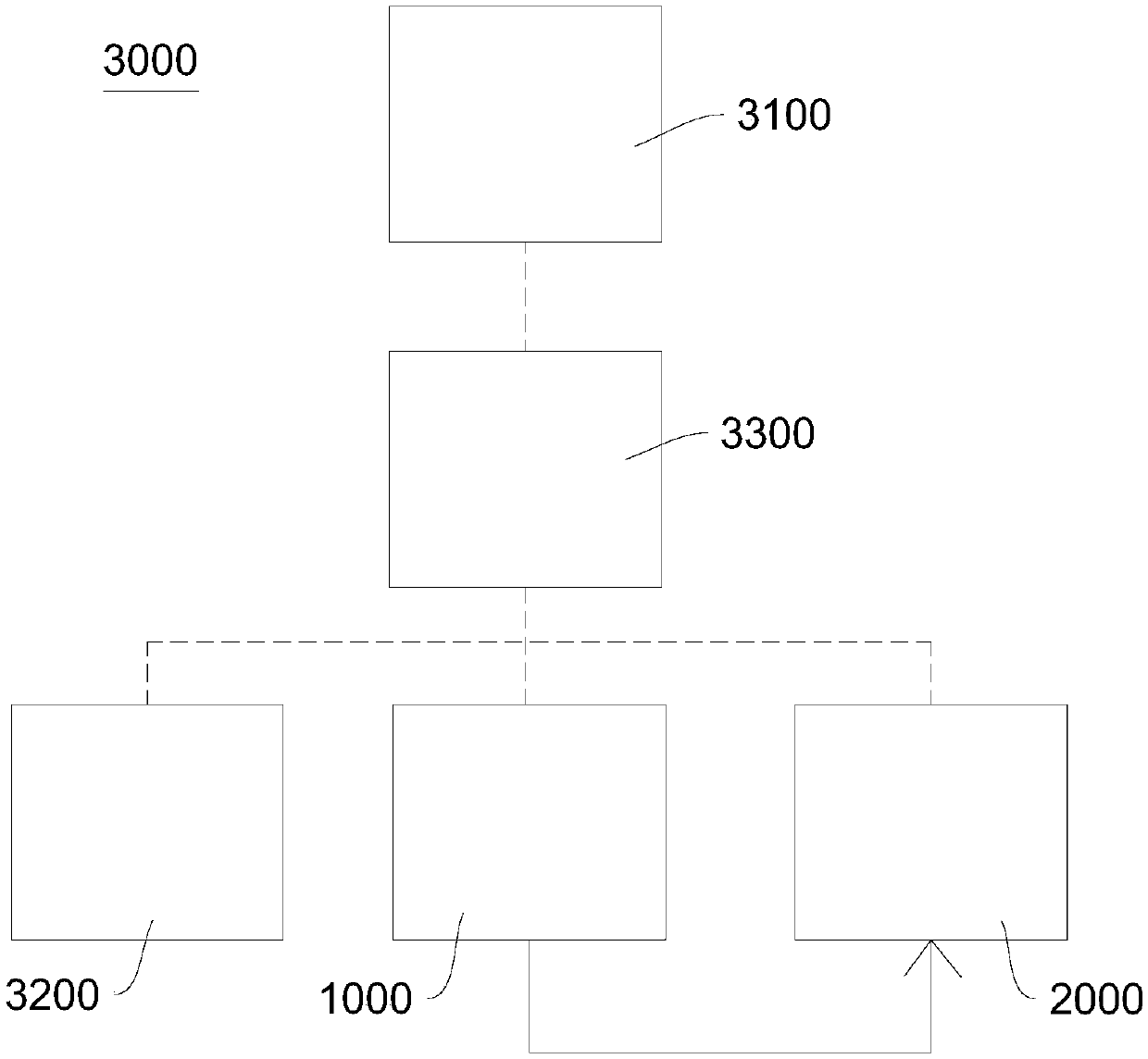

[0044] Please refer to Figure 1~3 , this embodiment provides a garment 3D printing production system 3000 . The clothing 3D printing production system 3000 includes: a human body 3D scanning device 3100 , a 3D printing device 3200 , a 3D printed clothing blank air support device 1000 and a control mechanism 3300 .

[0045] The human body 3D scanning device 3100 is used to scan human body 3D data for designing a suitable clothing 3D model.

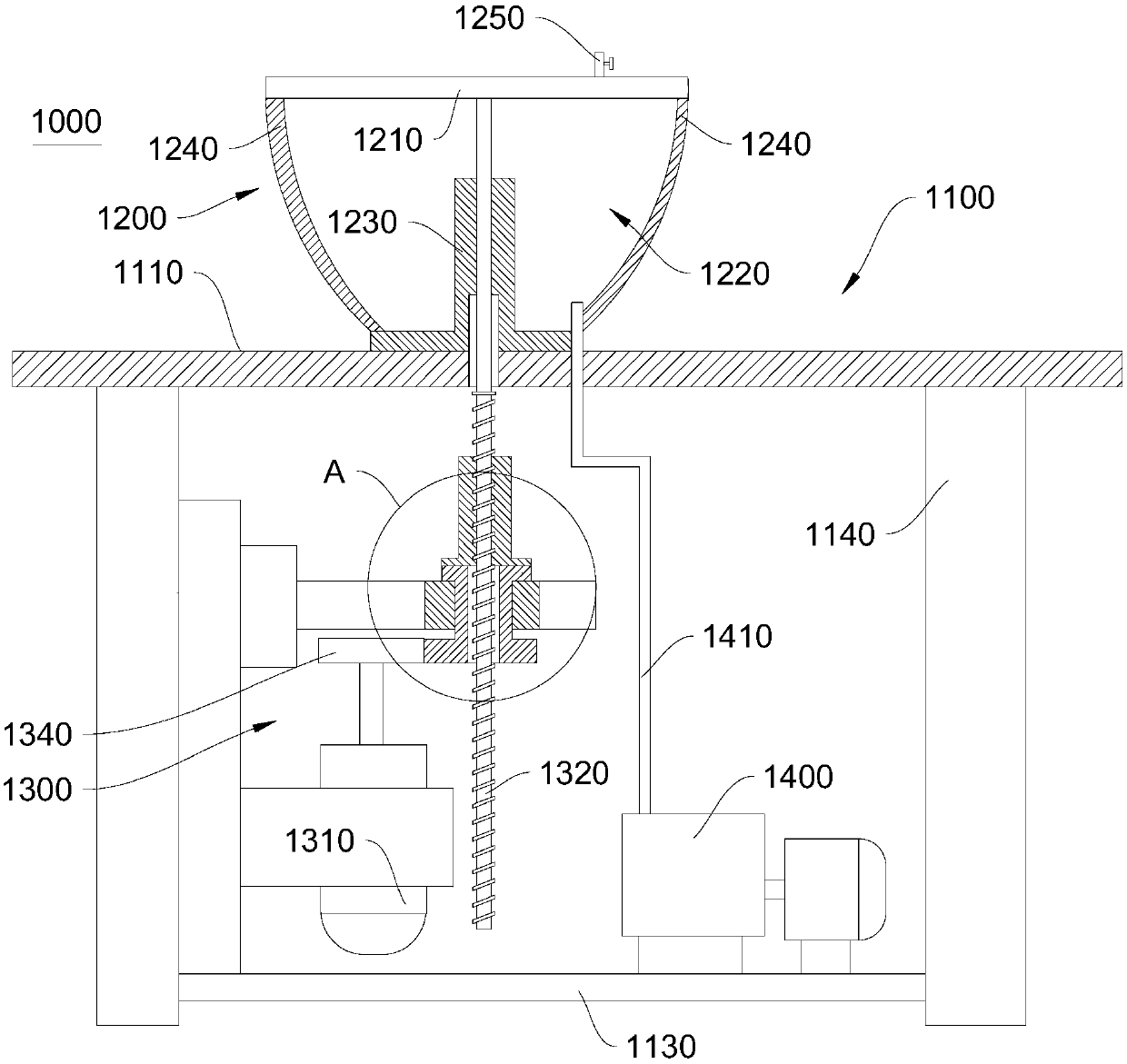

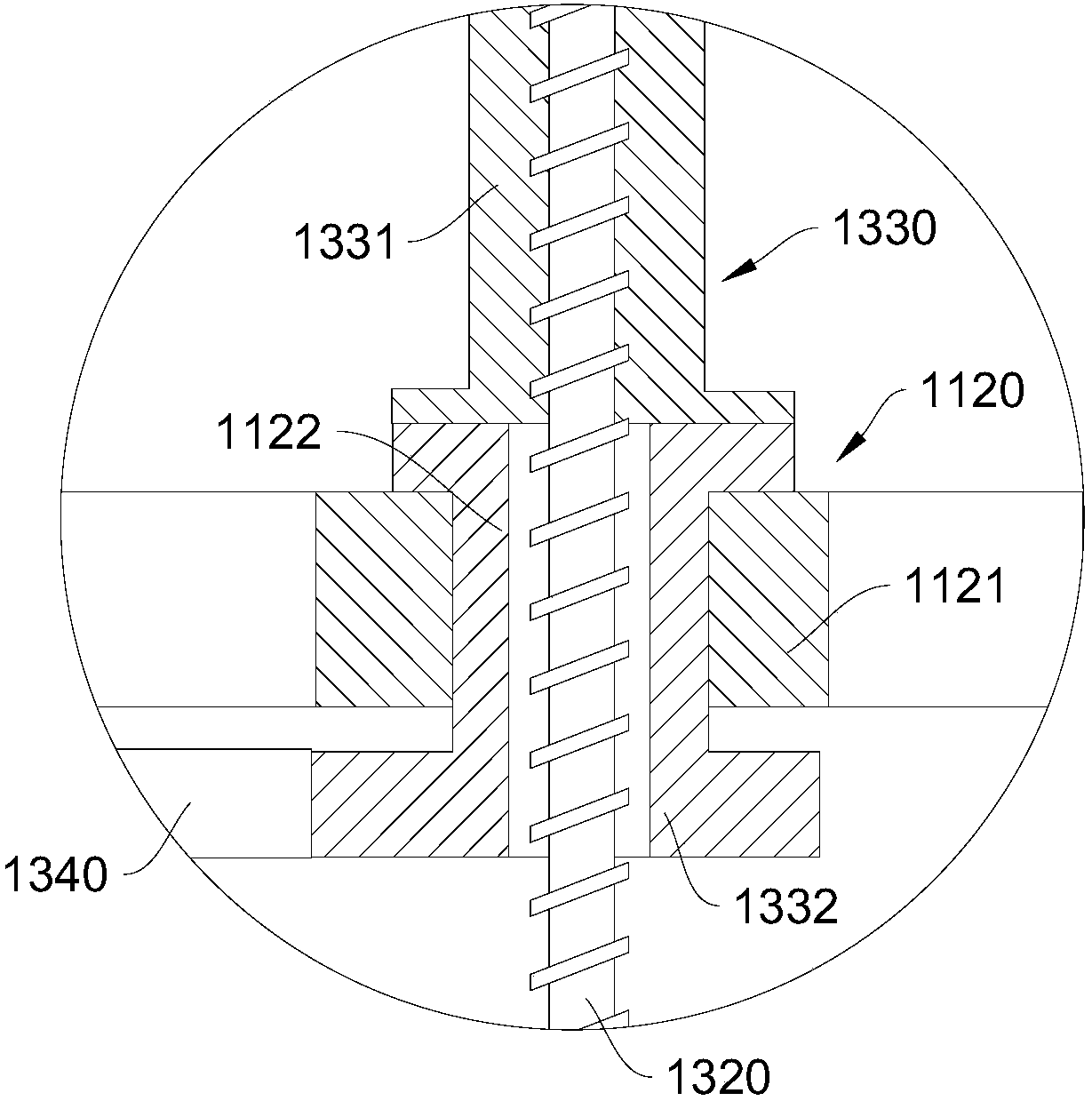

[0046] The air pressure support device 1000 for 3D printed clothing includes a support table 1100 , a support air bag 1200 , a driving mechanism 1300 and an air pump 1400 . The support airbag 1200 is set on the tabletop 1110 of the support table 1100 for 3D printing. The end of the support airbag 1200 away from the tabletop 1110 is connected with a stretching disc 1210 . The air outlet of the air pump 1400 communicates with the inner cavity 1220 of the support airbag 1200 . The driving mechanism 1300 includes a driver 1310 , a screw rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com