Electric automobile charging system and charging control system

A technology for electric vehicles and charging systems, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of difficult circuit design and high cost, and achieve improved redundancy and reliability, low cost, and circuit design. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

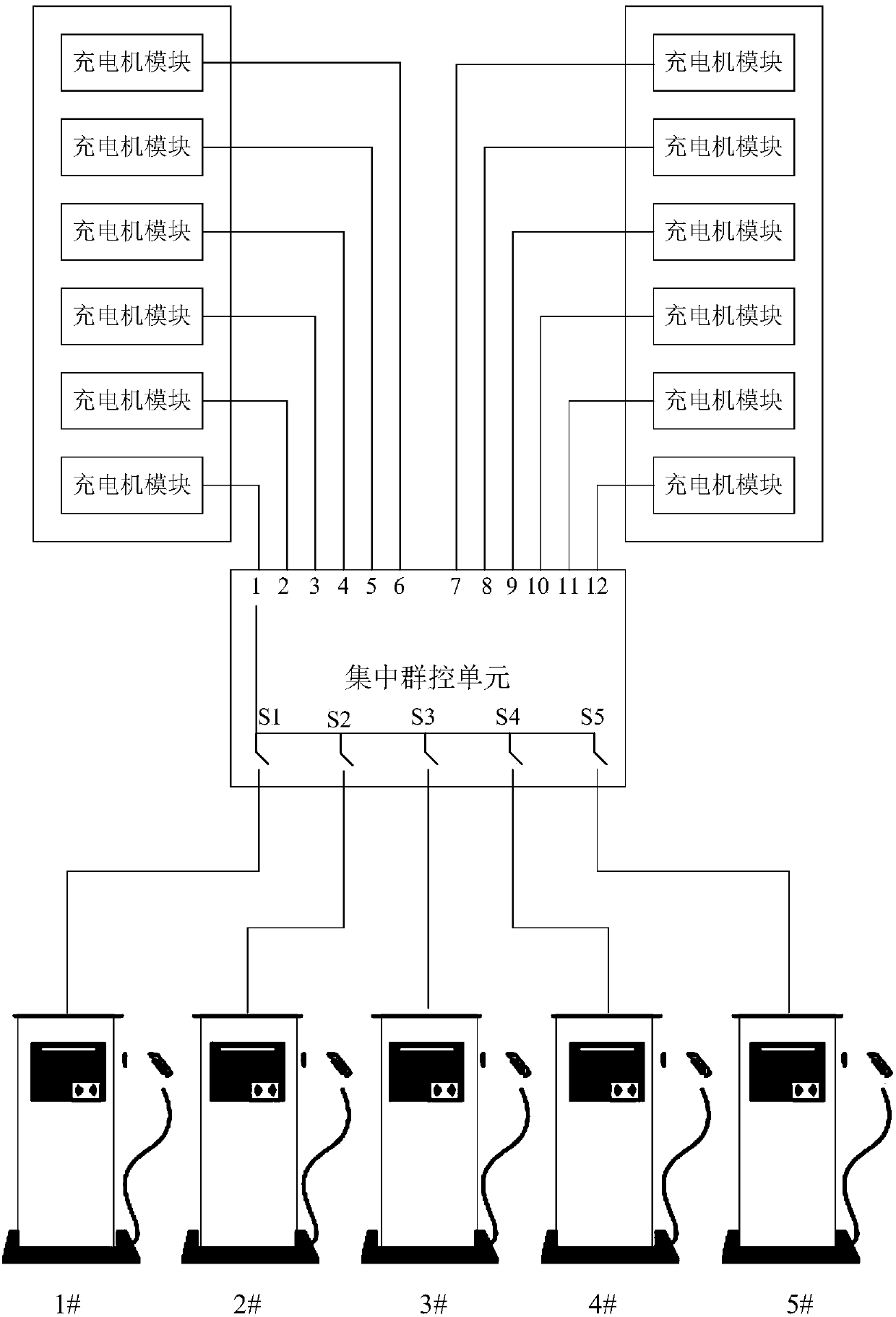

[0026] An electric vehicle charging system of the present invention includes a charging control system, a charger, and a charging pile. Among them, the charging control system includes a controller and a basic module unit for connecting the charger and the charging pile. The basic module unit has at least two levels. Each charger is connected to the charging pile through the basic module unit. The basic module unit of the previous level and the basic module unit of the subsequent level are connected in a tree shape. Each basic module unit includes one Input interface, two output interfaces, input interface strobes to connect two output interfaces. The basic module unit of the last stage of each charger is connected to all charging piles, and the last stage refers to the basic module unit whose output interface is not connected to any basic module unit. The controller is connected to at least two chargers, and each charger is connected to the charging pile through at least two-...

Embodiment 2

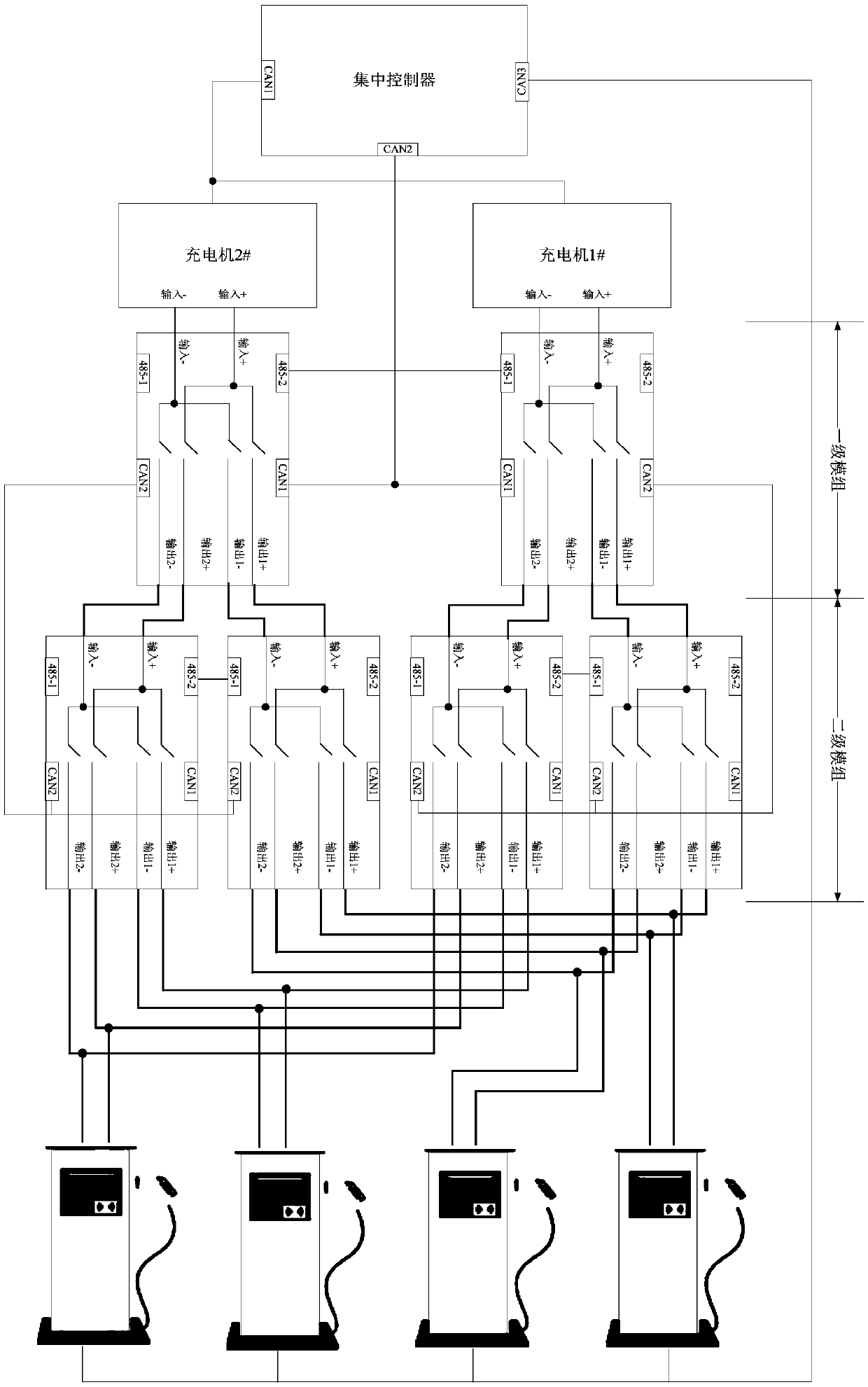

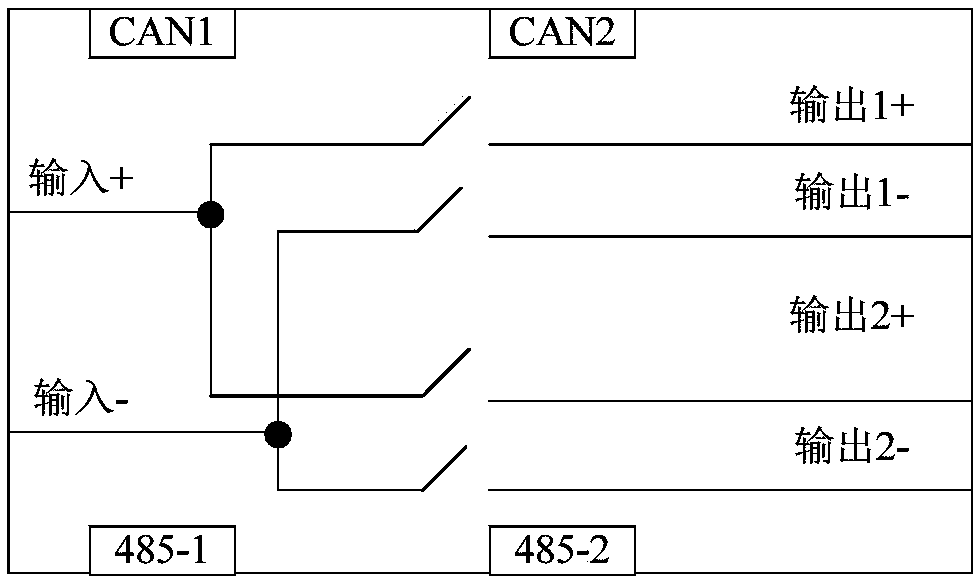

[0031] Such as image 3 The basic module unit shown is provided with 1 input interface, 2 output interfaces, 2 CAN communication interfaces, and 2 485 communication interfaces, and a switch is connected between the data interface and the output interface, and the switch is turned on. And shut-off is controlled by a centralized controller. Centralized controller such as Figure 4 As shown, there are 3 CAN communication interfaces, which are respectively responsible for communicating with the charging pile, the charger, and the basic module.

[0032] The electric vehicle charging system mainly composed of the above-mentioned basic module units and centralized controllers such as figure 2 As shown, the centralized controller is connected to charger 1# and charger 2#, namely charger 1 and charger 2, through the communication interface CAN1, and both chargers are connected through their respective primary and secondary modules Charging pile, where the first-level module corresponding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com