Beverage bottle cap with bubble cover

A technology for blisters and beverages, applied to caps with auxiliary devices, containers with multiple items, sealing parts with auxiliary devices, etc., can solve the production cost of beverage pollution in the bottle, the sealing of beverage bottle caps is not strict, Problems such as weak connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

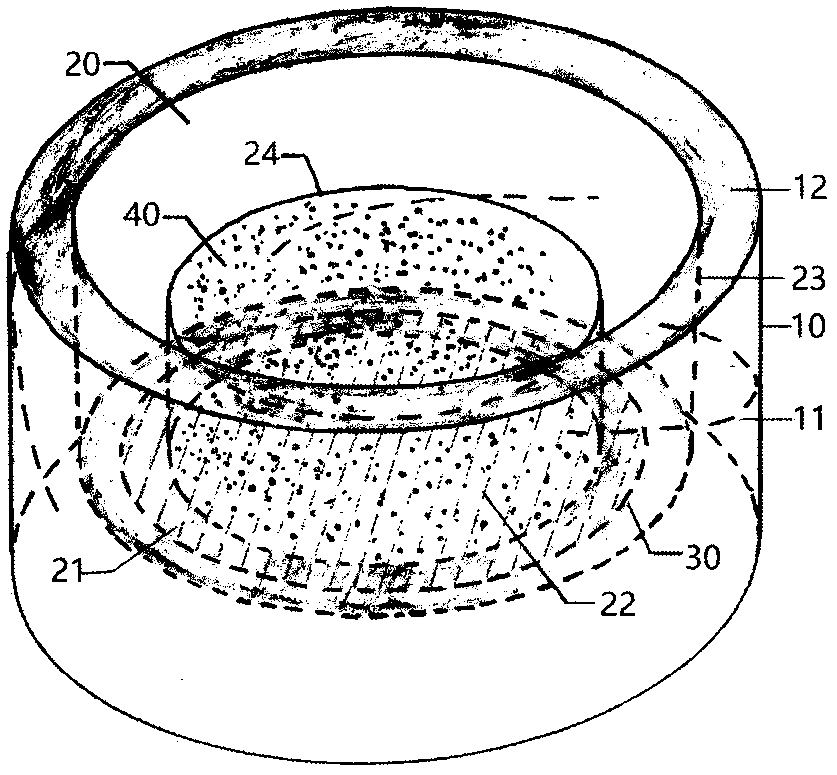

[0021] Such as figure 1 As shown, there is a bottle cap groove 20 on the top of the beverage bottle cap, and the bottle cap groove 20 has a blister 24. The blister 24 is an integral part of the bottle cap groove 20, and the blister opening 22 is in the bottle cap groove. On the plastic sheet 21 at the bottom of 20, the blister 24 is directly formed by injection molding or formed by blistering of the plastic sheet 21 at the bottom of the bottle cap groove 20. The blister opening 22 is covered and sealed by a film 30 containing aluminum foil. The blister 24 and the bottle cap are concave There is only one groove 20, and there is a beverage condiment 40 in the blister 24, and the blister opening 22 is directed downward toward the mouth of the beverage bottle. Cap groove 20 radius.

[0022] There is a bottle cap thread 11 on the side wall 10 of the beverage bottle cap, and there is a gap between the side wall 10 of the beverage bottle cap and the side wall 23 of the groove. Ther...

Embodiment 2

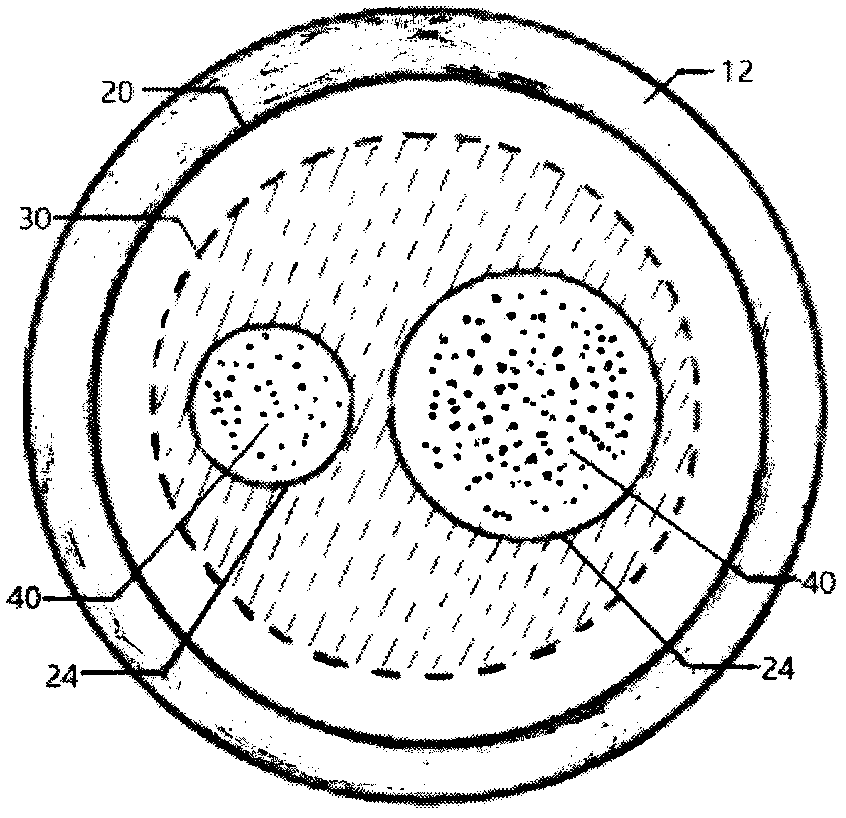

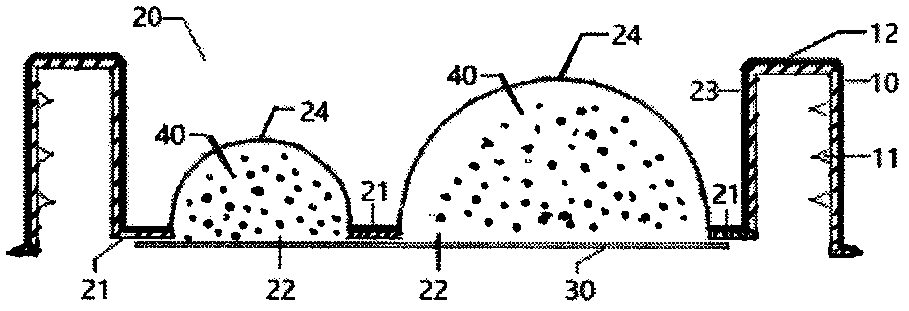

[0025] Such as figure 2 , image 3 As shown, there is a bottle cap groove 20 on the top of the beverage bottle cap, and the bottle cap groove 20 has a blister 24. The blister 24 is an integral part of the bottle cap groove 20, and the blister opening 22 is in the bottle cap groove. On the plastic sheet 21 at the bottom of 20, the blister 24 is directly formed by injection molding or formed by blistering of the plastic sheet 21 at the bottom of the bottle cap groove 20, the blister opening 22 is covered and sealed by a film 30 containing aluminum foil, and the beverage bottle cap has a bottle cap Groove 20, there are two blisters 24 in the groove 20 of the bottle cap, and there is a kind of beverage condiment 40 in each blister 24, and the direction of the blister opening 22 is downward toward the mouth of the beverage bottle, and the depth of the blister 24 is smaller than that of the corresponding bottle. The depth of the cap groove 20 and the radius of the blister 24 are s...

Embodiment 3

[0029] Such as Figure 4 , Figure 5 As shown, there is a bottle cap groove 20 on the top of the beverage bottle cap, and the bottle cap groove 20 has a blister 24. The blister 24 is an integral part of the bottle cap groove 20, and the blister opening 22 is in the bottle cap groove. On the plastic sheet 21 at the bottom of the bottle cap 20, the blister 24 is directly formed by injection molding or formed by blistering of the plastic sheet 21 at the bottom of the bottle cap groove 20. The blister opening 22 is covered and sealed by a film 30 containing aluminum foil. The bottle cap groove 20 has two Each bottle cap groove 20 has a blister 24, a beverage condiment 40 is arranged in each blister 24, the blister opening 22 direction is downwards towards the beverage bottle mouth, and the depth of the blister 24 is smaller than that of the corresponding bottle cap. The depth of the groove 20 and the radius of the blister 24 are smaller than the radius of the corresponding bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com