A kind of foaming material of high resilience composition for shoe sole and preparation method thereof

A technology of foaming material and high resilience, which is applied in the fields of foaming material and its preparation, high resilience composition foaming material for shoe soles and its preparation, and can solve the problem of large permanent deformation and large loss of resilience of foamed EVA materials , poor wear resistance and other problems, to achieve the effect of improving resilience, excellent resilience, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

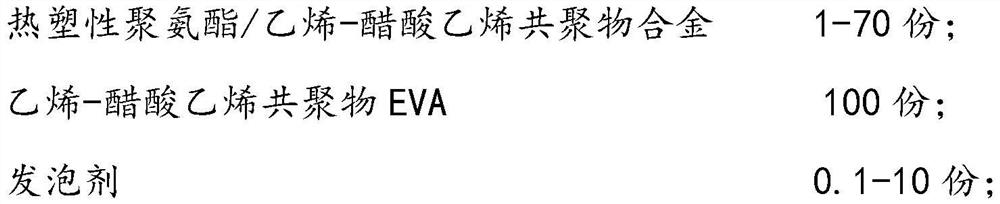

Method used

Image

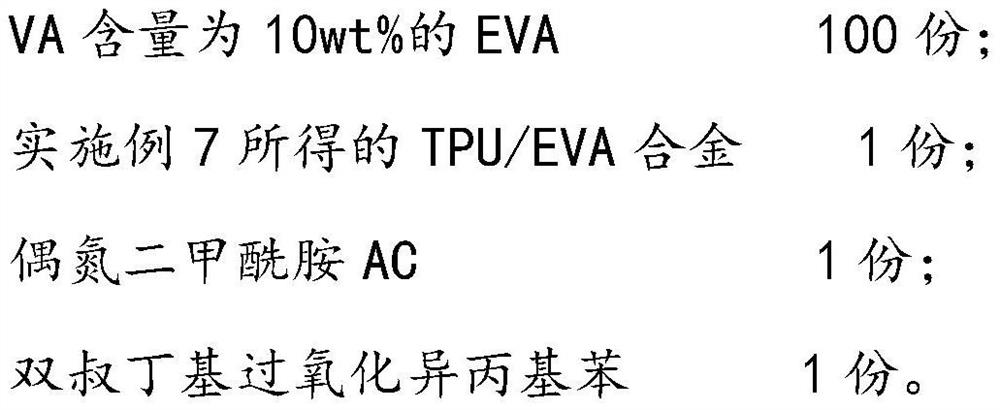

Examples

Embodiment 1

[0036] A kind of technique for preparing TPU alloy material, comprises the steps:

[0037] 1) 68 parts of polyester polyols, 6 parts of BDO, and 26 parts of diphenylmethane diisocyanate MDI with a molecular weight of 2000g / mol are added to the feed port of the twin-screw extruder, and 95 parts of EVA, MAH (maleic anhydride ) 10 parts and 5 parts of initiator DCP (dicumyl peroxide) are injected in the twin-screw extruder by side feeding;

[0038] 2) Control the temperature in the reaction zone of the twin-screw extruder to 140-200°C, and the temperature in the cooling zone to 90-110°C, and the extruded material is cut and granulated underwater;

[0039] 3) drying the granulated product obtained in step 2).

Embodiment 2

[0041] A kind of technique for preparing TPU alloy material, comprises the steps:

[0042] 1) 55 parts of polyester polyols, 7 parts of BDO, and 38 parts of diphenylmethane diisocyanate MDI with a molecular weight of 1500g / mol are added to the feed port of the twin-screw extruder, and 75 parts of EVA, MAH (maleic anhydride ) 5 parts and 0.2 part of initiator DCP (dicumyl peroxide) are injected in the twin-screw extruder by side feeding;

[0043] 2) Control the temperature in the reaction zone of the twin-screw extruder to 50-250°C, and the temperature in the cooling zone to 90-110°C, and the extruded material is cut and granulated underwater;

[0044] 3) drying the granulated product obtained in step 2).

Embodiment 3

[0046] A kind of technique for preparing TPU alloy material, comprises the steps:

[0047] 1) the molecular weight of 70 parts by weight is the polyether polyol of 1800g / mol and 5 parts of BDO, toluene diisocyanate TDI 25 parts join the feed port of twin-screw extruder, 65 parts of EVA (Mitsui Chemicals' 150Y), 0.1 part of acrylic acid and 0.1 part of initiator DCP (dicumyl peroxide) are injected into the twin-screw extruder by side feeding;

[0048] 2) Control the temperature in the reaction zone of the twin-screw extruder to 140-180°C, and the temperature in the cooling zone to 90-110°C, and the extruded material is cut and granulated underwater;

[0049] 3) drying the granulated product obtained in step 2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com