Gear type underground coal bunker walling crib and construction method of coal bunker provided with walling crib

A gear type and coal bunker technology, which is applied to shaft lining, underground chamber, shaft equipment, etc., can solve the problems of high cost, heavy workload and difficult construction, and achieve the effect of low cost, simple construction and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

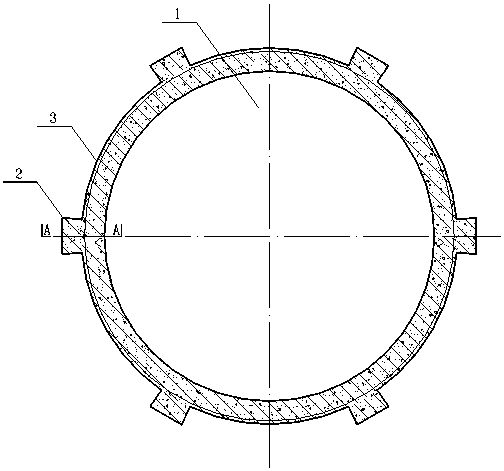

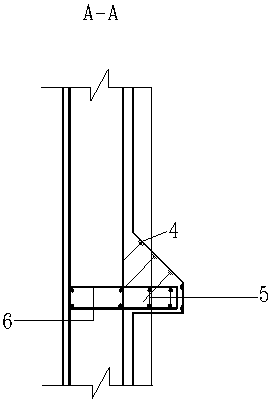

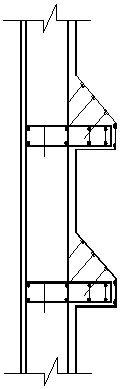

[0031] Such as figure 1 , figure 2 , image 3 As shown, a gear-type underground coal bunker wall seat includes a wall seat body 2, the shape of the wall seat body 2 is a gear tooth shape, and the wall seat body 2 is a concrete reinforcement structure. A number of anchor rods 4 are arranged obliquely inside the wall base body 2, and the anchor rods 4 are perpendicular to the inclined surface of the wall base body 2; the wall base body 2 is provided with connecting ribs 5 for connecting with the coal bunker wall body 3 as a whole.

[0032] The coal bunker wall body 3 is also a reinforced concrete structure. The inside of the coal bunker wall body 3 is provided with an annular rib 6, and the connecting rib 5 and the annular rib 6 are connected as one. Rib 6 is connected as an integral structure.

[0033] For the coal bunker wall with the gear type underground coal bunker wall seat, several coal bunker wall seats are arranged outside the coal bunker wall body 3 . Coal bunker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com