Testing system for sealing performance of motor and control method thereof

A test system and control method technology, applied in the direction of liquid tightness measurement using liquid/vacuum degree, and detecting the appearance of fluid at the leakage point, etc., can solve the problems that are not suitable for mass production, heavy labor load of workers, and potential safety hazards, etc. Problems, to achieve the benefits of industrial automation, improve detection efficiency, and avoid the effect of loose assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

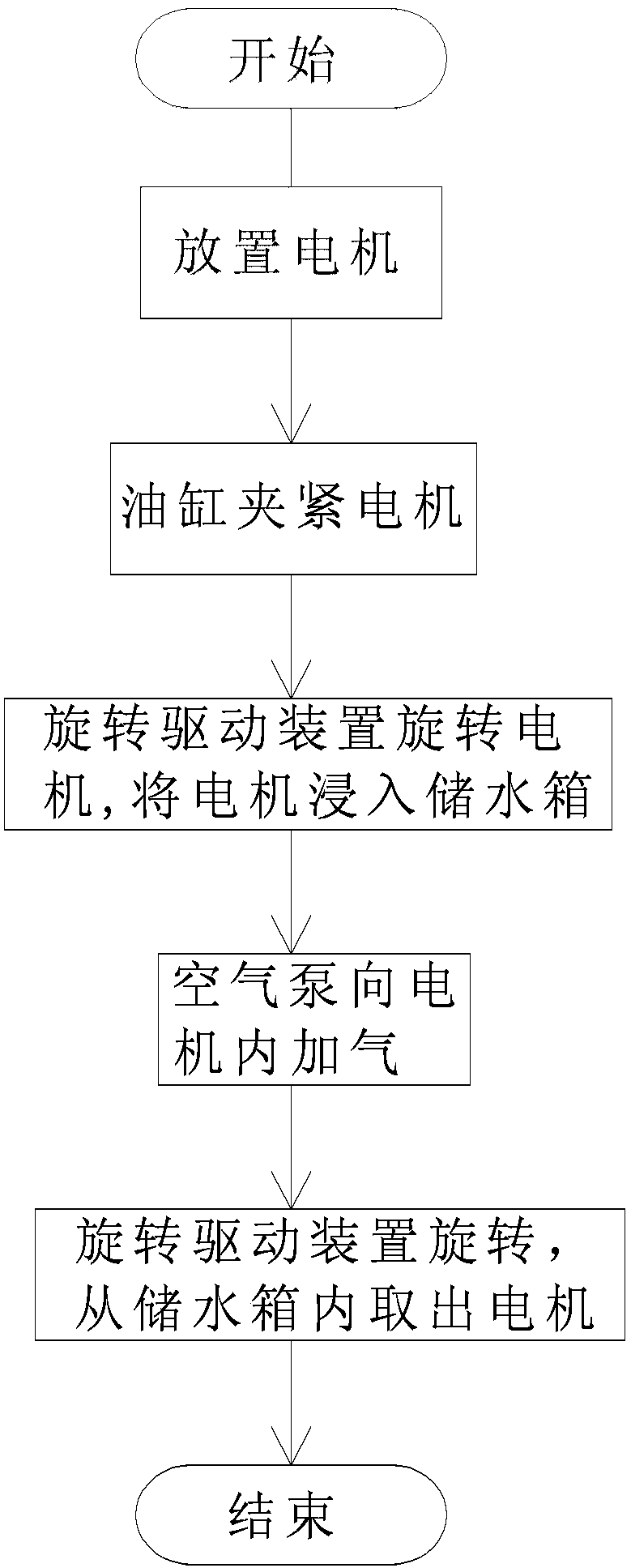

[0049] The invention provides a motor sealing test system. Change the traditional idea of hoisting and bolt locking and sealing, and use the method of turning the motor into the water and clamping at both ends, which greatly improves the reliability of the operation and increases the production efficiency by more than 50%.

[0050] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

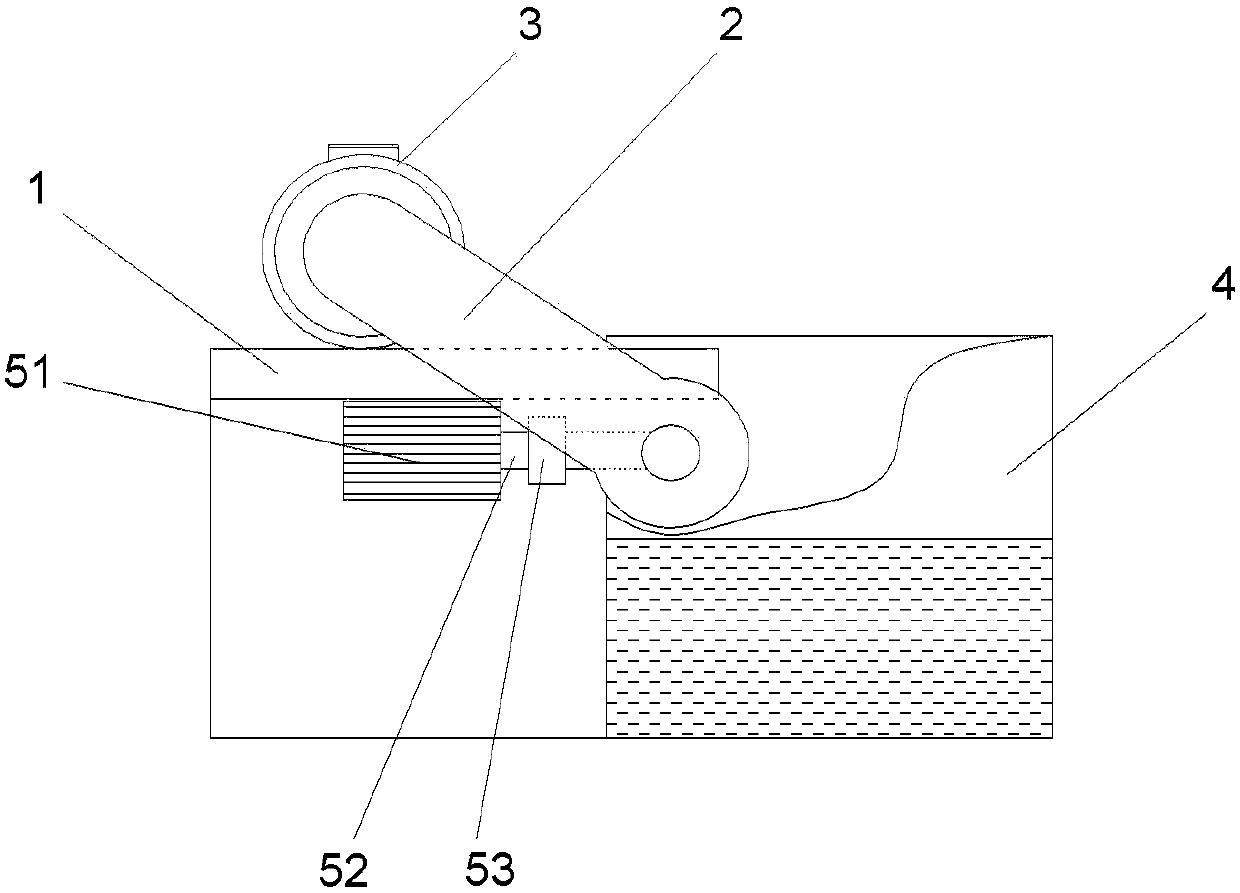

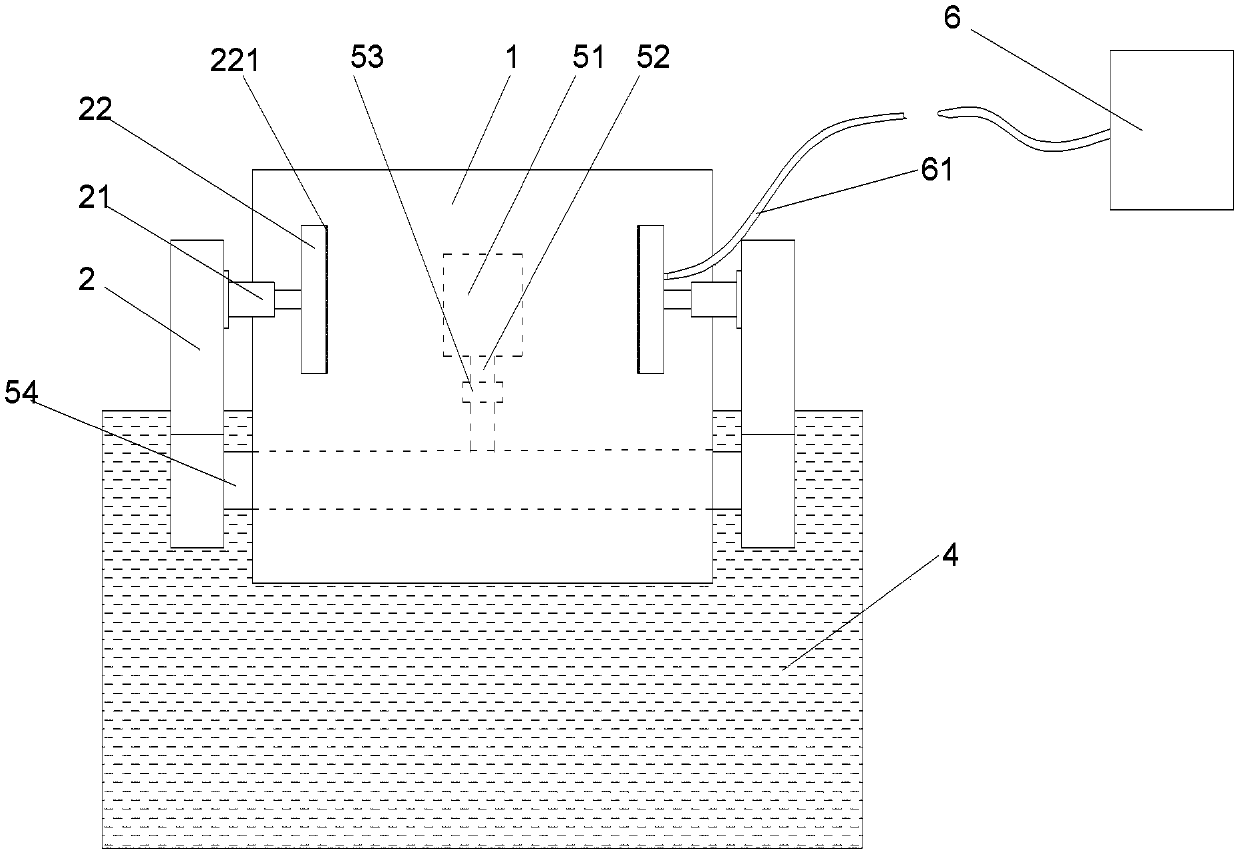

[0051] In an exemplary embodiment of the present invention, a motor sealing test system is provided, and no end caps are installed on the end faces of the tested motor axial sides, such as figure 1 , figure 2 As shown, the present invention includes a material platform 1 , a sealing clip device, a rotary drive device, an air pump 6 and a water storage tank 4 .

[0052] Each component of this embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com