Emulsion paint film maintaining device and test method of color-modulable emulsion paint color stability

A testing method, technology of latex paint, applied in color/spectral characteristic measurement, device for coating liquid on surface, surface pretreatment, etc., can solve unqualified color stability test, unspecified stirring time, uniform mixing understanding There are problems such as deviation, to achieve the effect of small size, light weight, easy temperature control, and small thermal inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

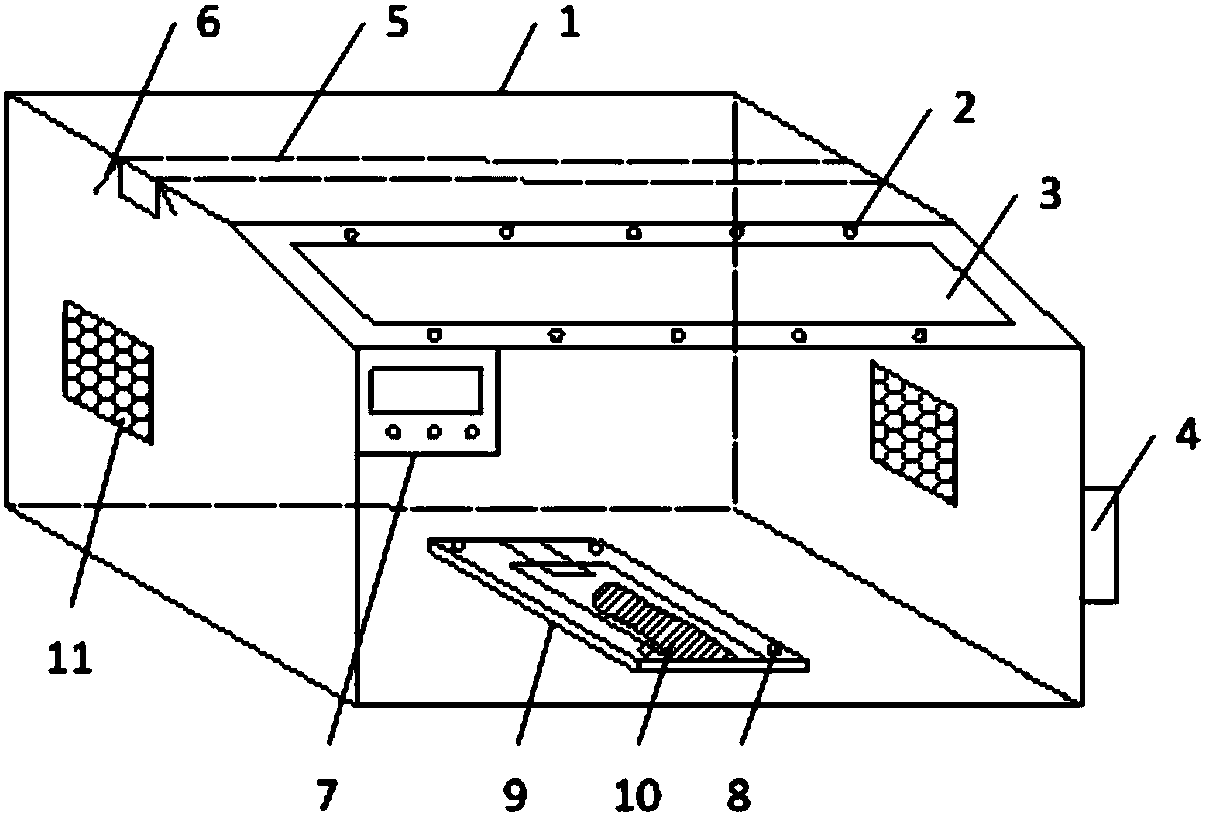

[0046] Embodiment 1 A kind of latex paint paint film curing device

[0047] A kind of latex paint film maintenance device, such as figure 1 As shown, the device includes: a box body 1 provided with vents 11 on the opposite side wall, and a side door 4 is also provided on one side wall of the box body 1; The magnifying glass panel 3 in the paint film state; the LED lamp bead 2 arranged on the edge of the magnifying glass panel 3 for improving the brightness of the box body 1; A short-wave infrared heating lamp 5; a sample stage 9 for fixing a white paper card 10 arranged on the bottom wall of the box body 1; a thermal induction element 8 arranged on the edge of the sample stage 9 for measuring the temperature of the sample stage 9; The device also includes a control device 7 for controlling the LED lamp bead 2, the short-wave infrared heating lamp 5 and the thermal induction element 8, and the control device 7 is connected with the LED lamp bead 2, the short-wave infrared heat...

Embodiment 2

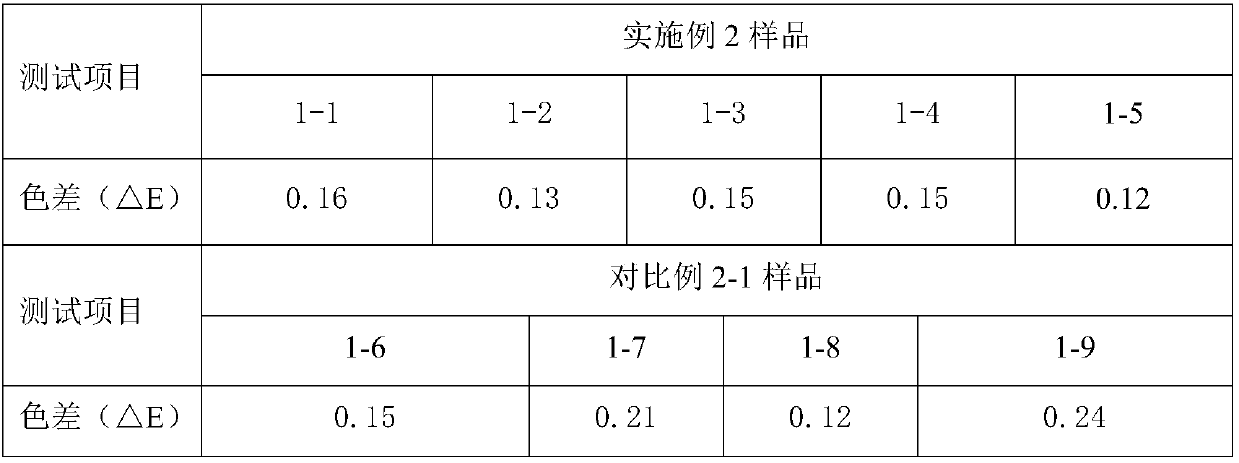

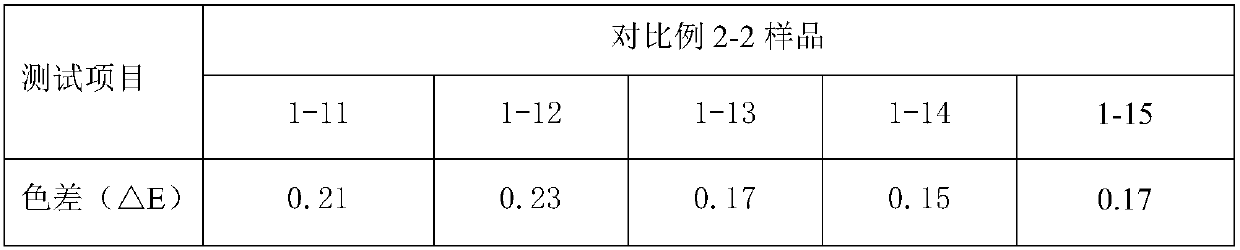

[0054] Jingwei 120 Bamboo Charcoal 3 in 1 No Additive Interior Wall Latex Paint Color Stability Test, the method is as follows:

[0055] Accurately test the dilution densities of the Net Taste 120 Bamboo Charcoal 3-in-1 No Additive Interior Wall Latex Paint and the reference paint, which are 1.374g / ml and 1.373g / ml respectively; add 1.511g and 1.534g to the mixing container Color paste (color paste density is 1.371g / ml), and add 90.858g of the sample paint to be tested and 92.174g of the reference paint at a volume ratio of 1:60, shake in a shaker for 3 minutes and prepare with a 250μm wet film Paint film on a white paper card, maintain in the latex paint film maintenance device of embodiment 1 for 15 minutes, and test the results on a double-beam spectrophotometer. The cured paint films were randomly marked as samples 1-1, 1-2, 1-3, 1-4, and 1-5; the results are shown in Table 1.

[0056] Wherein, the determination method of described dilution density is: 1) weighing test ne...

Embodiment 3

[0071] Nippon "porcelain clean taste full effect" interior wall latex paint, the method is as follows:

[0072] Accurately test the dilution density (concrete method is the same as embodiment 2) of the Nippon State "porcelain clean and taste full effect" interior wall latex paint and reference sample paint to be tested, which are respectively 1.441g / ml and 1.443g / ml; Add 1.503g and 1.512g of color paste (the density of color paste is 1.371g / ml) into the container respectively, add 94.784g of the paint to be tested and 95.484g of the reference paint at a volume ratio of 1:60, and shake in the shaker After 3 minutes, use a 250 μm wet film preparation device to coat a film on a white paper card, maintain it in the latex paint film maintenance device of Example 1 for 15 minutes, and test the results on a double-beam spectrophotometer. The cured coating film is randomly marked as samples 2-1, 2-2, 2-3, 2-4, 2-5 and the rest conditions remain unchanged; the results are shown in Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com