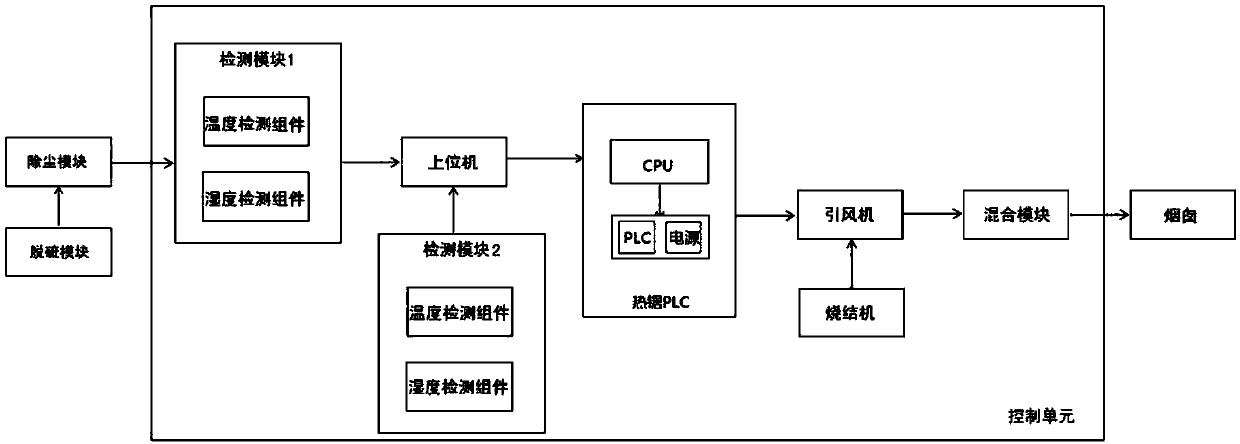

White smoke eliminating control system and method thereof

A control system and white smoke technology, applied in the field of flue gas purification, can solve the problems of low elimination efficiency, steel structure corrosion, and reduced service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific examples.

[0022] Sulfur dioxide is one of the main air pollutants faced by mankind today, and its pollution sources are divided into two categories: natural pollution sources and man-made pollution sources. Natural pollution sources do little harm to the environment because of their small amount, wide area, and easy dilution and purification, while man-made pollution sources cause serious harm to the environment due to their large amount, concentration, and high concentration.

[0023] For a long time, all countries in the world are committed to the treatment of sulfur-containing flue gas. Among them, the flue gas with a volume content of sulfur dioxide above 3.5% generally adopts the contact method to make acid. This method can not only control the pollution of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com