Full-chain catering production and distribution ripening method

A full-chain, ripening technology, applied in instruments, individual input/output port registers, data processing applications, etc., can solve problems such as difficult control of food quality, potential safety hazards, and reduced user experience. The effects of human health, easy standardization, and controllable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

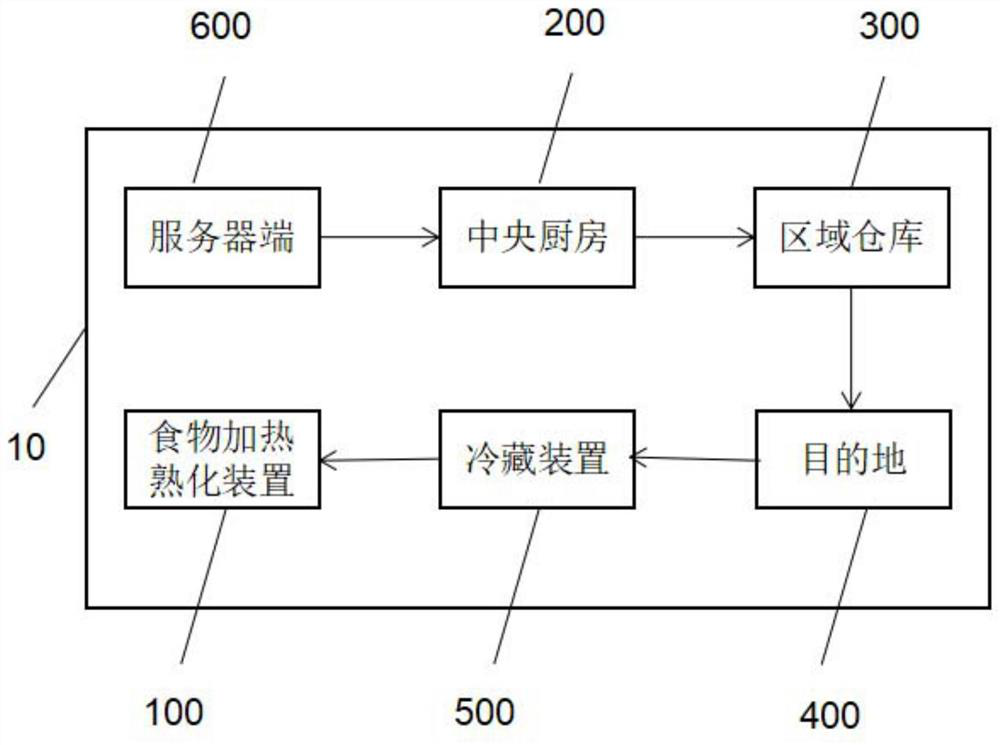

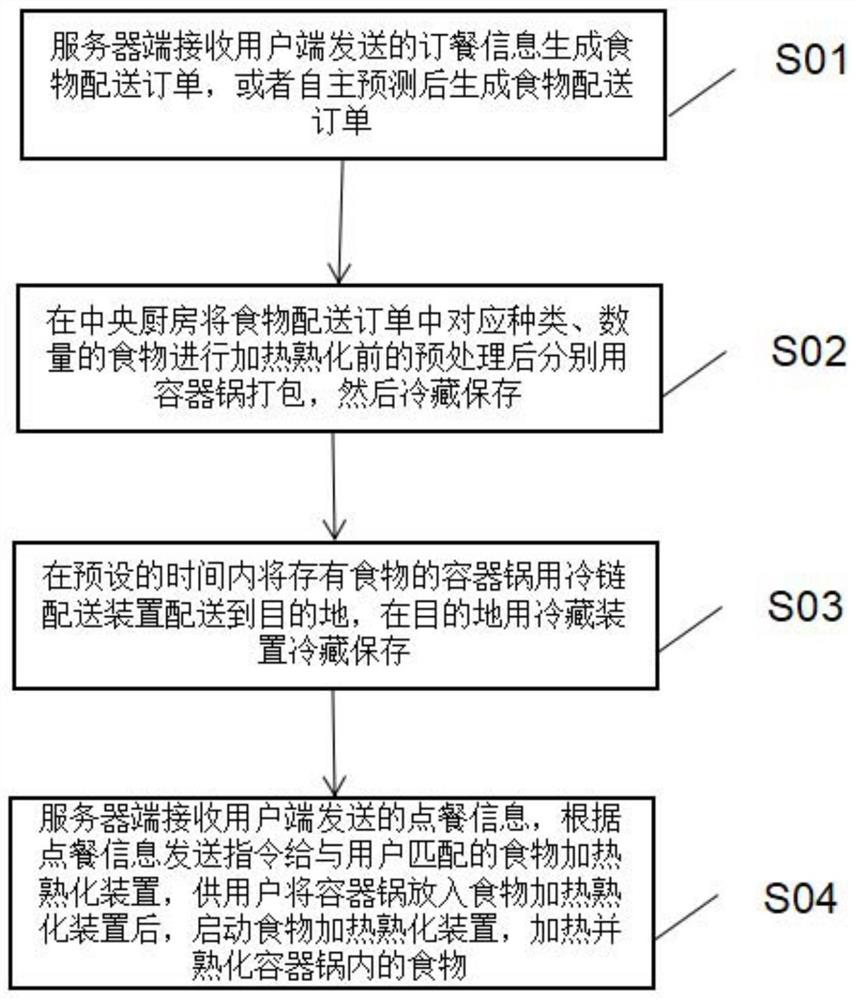

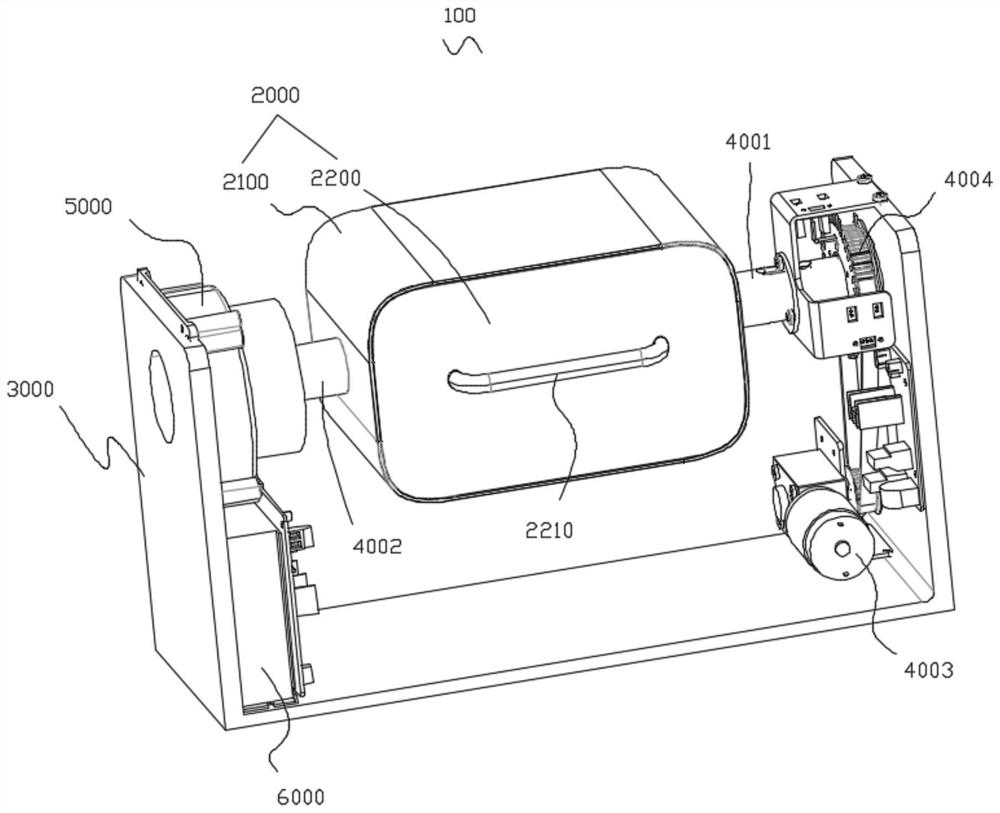

[0042] Please also refer to figure 1 , this embodiment provides a full-chain catering production and distribution ripening system 10 . Specifically, the full-chain catering production, distribution and cooking system 10 includes a server end 600 , a central kitchen 200 , a container pot, a cold chain distribution device, a refrigeration device 500 and a food heating and curing device 100 . Wherein, the food heating and cooking device 100 is used for heating the food in the cooking container pot.

[0043] Wherein, the server end 600 is used to generate food delivery orders. As a preferred server end 600, it includes a storage unit, a control unit, a communication unit, input and output interfaces, and the like.

[0044] Wherein, the central kitchen 200 is used for preprocessing the corresponding types and quantities of food in the food delivery order before heating and cooking, and then packing them in container pots respectively, and then storing them in cold storage. As a ...

Embodiment 2

[0086] Compared with embodiment 1, the main difference of this embodiment is:

[0087] The range hood 5000 is configured to be separated from the frame 3000, and is used for exhausting the oil fume in the container pot 1000 to the outside. Correspondingly, the oil fume purification device 6000 is not included in this embodiment.

[0088] Other features in this embodiment are the same as those in Embodiment 1 and will not be further described.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com