Cover plate of electronic equipment, preparation method of cover plate and electronic equipment

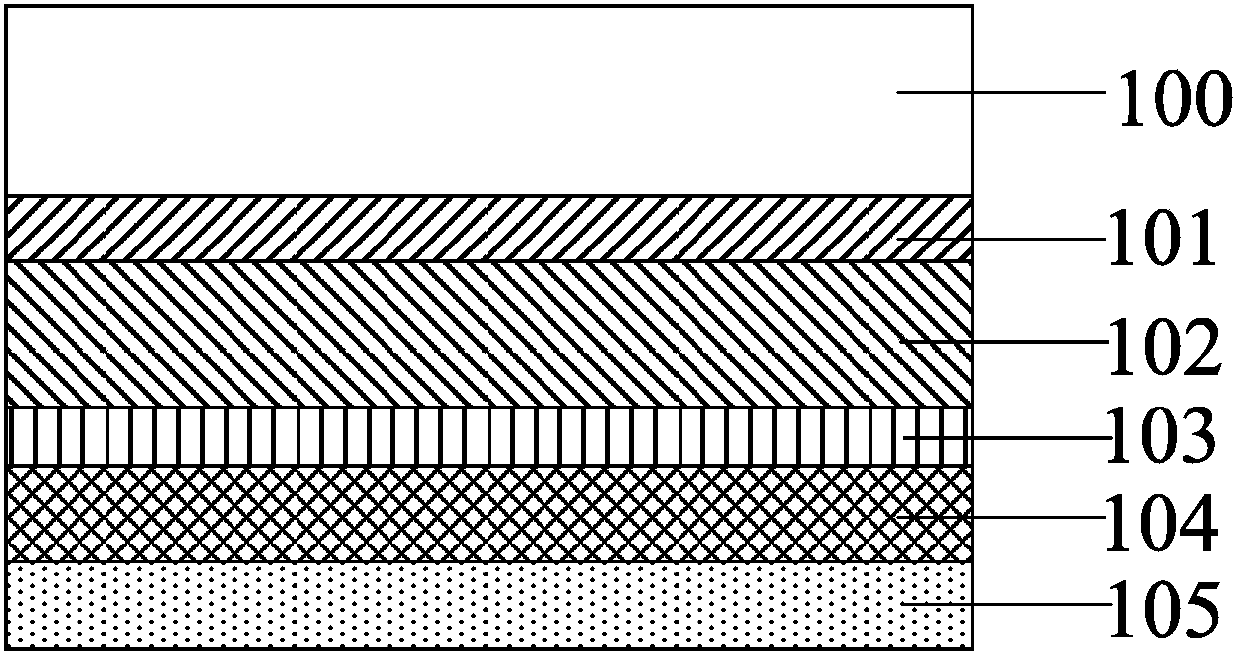

A technology for electronic equipment and cover plates, which is applied to electrical equipment shells/cabinets/drawers, electrical components, and processes for producing decorative surface effects, etc., which can solve problems such as expensive consumables, cumbersome processes, and low product yields , to achieve the effect of simple process, simple cover plate structure and improved product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following description is a preferred embodiment of the present invention, it should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also considered Be the protection scope of the present invention.

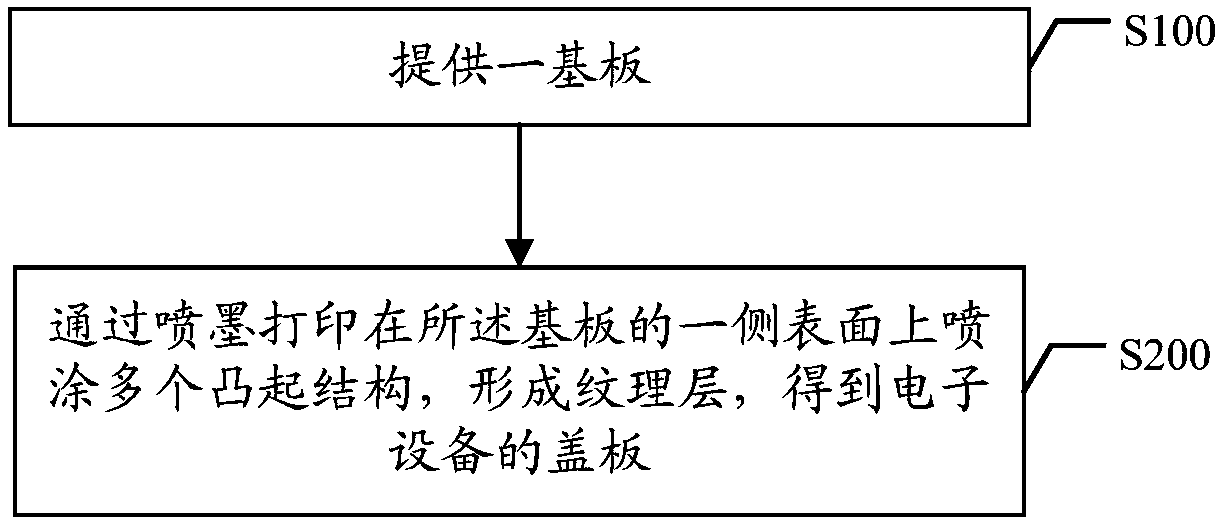

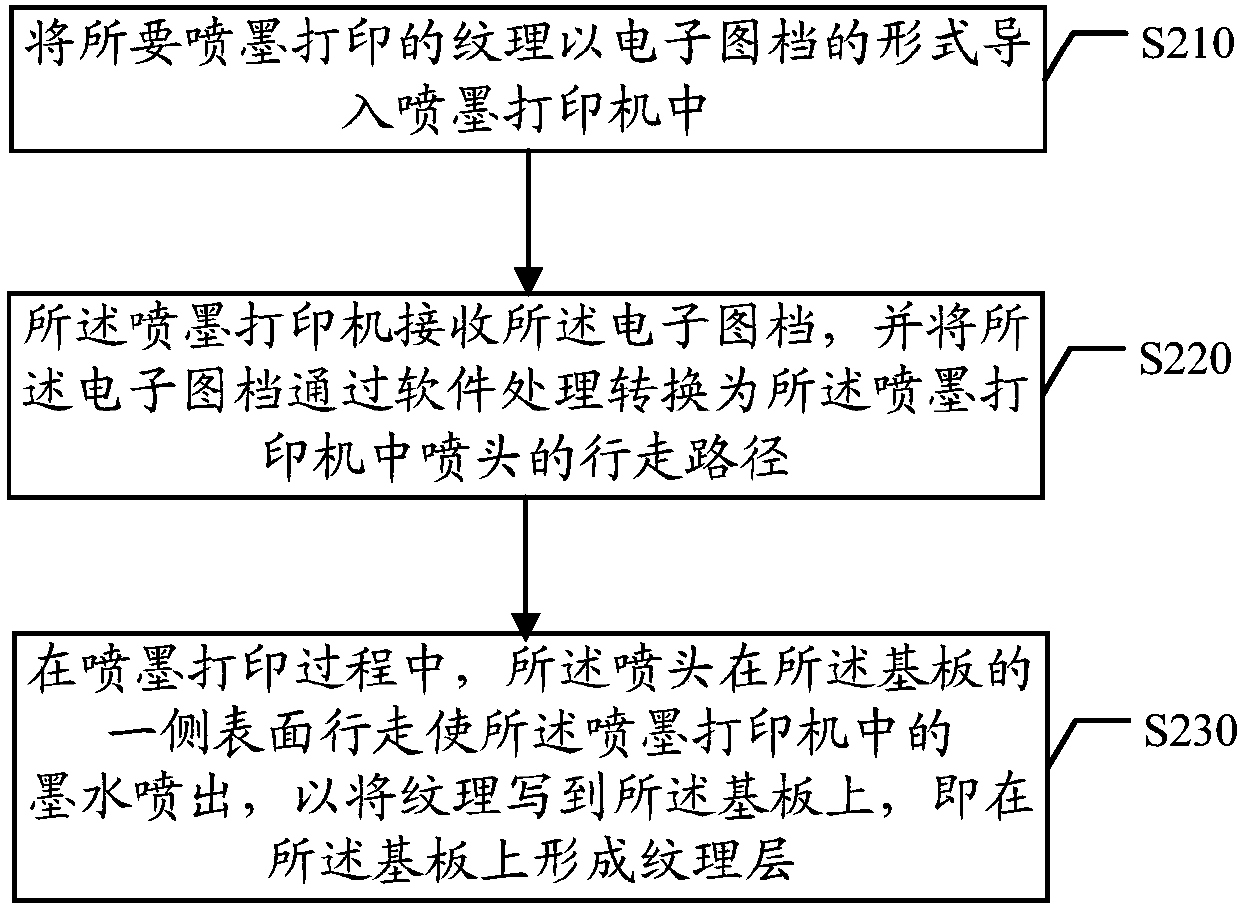

[0048] An embodiment of the present invention provides a method for preparing a cover plate of an electronic device, please refer to figure 2 , figure 2A flowchart of a method for preparing a cover plate of an electronic device provided by an embodiment of the present invention. The preparation method of the cover plate of the electronic equipment includes but not limited to the following steps.

[0049] Step S100, providing a substrate.

[0050] Step S200, spraying a plurality of raised structures on one side of the substrate by inkjet printing to form a textured layer to obtain a cover plate for an ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com