Bucket for swinging rotor of centrifugal separator

A centrifugal separator and rotor technology, which is applied to the barrel field of the swing rotor to ensure the sealing performance and easy handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

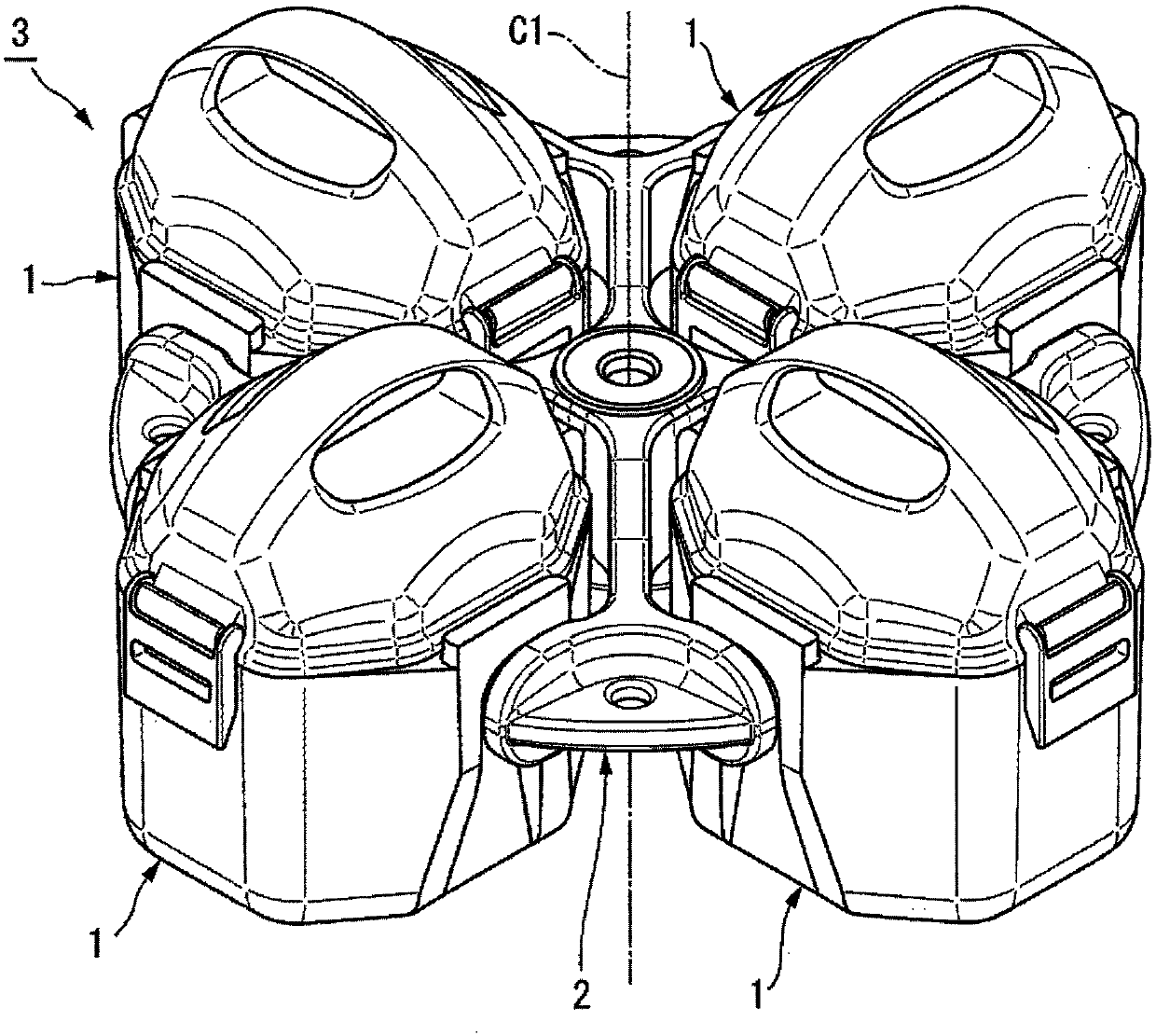

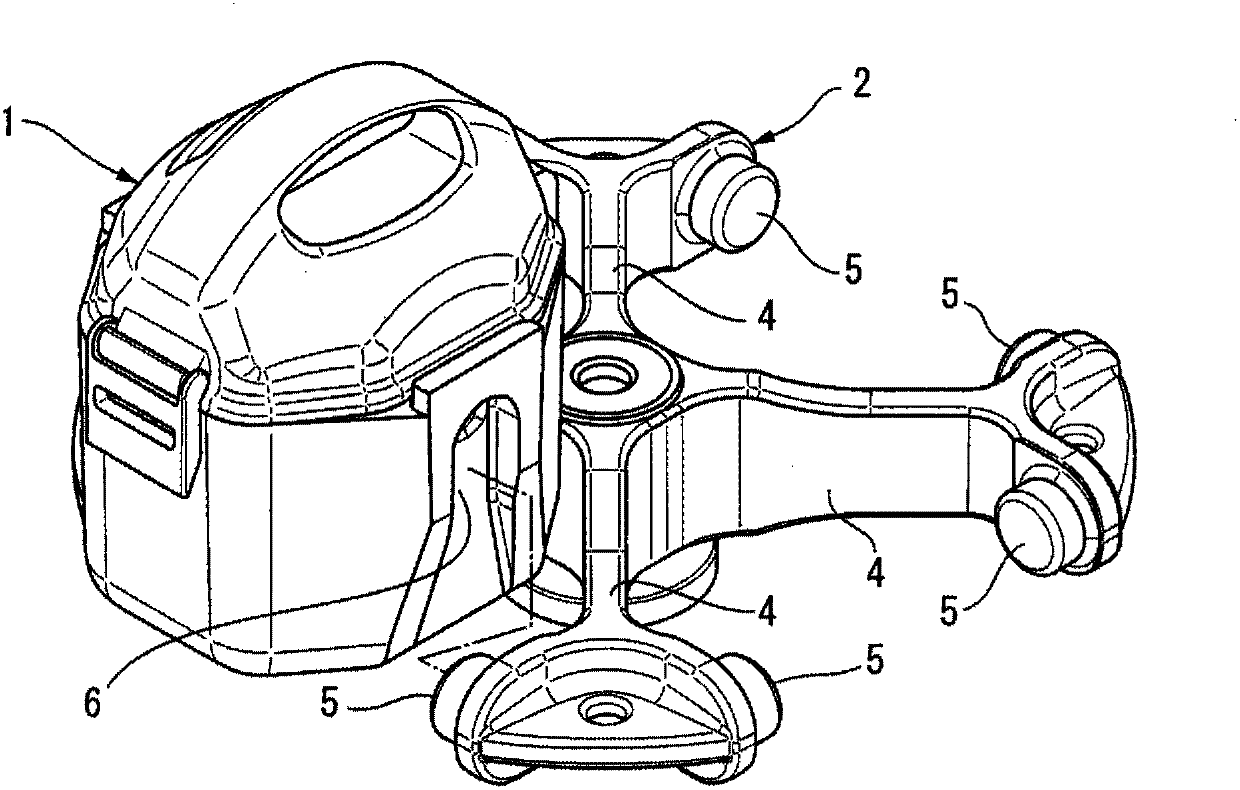

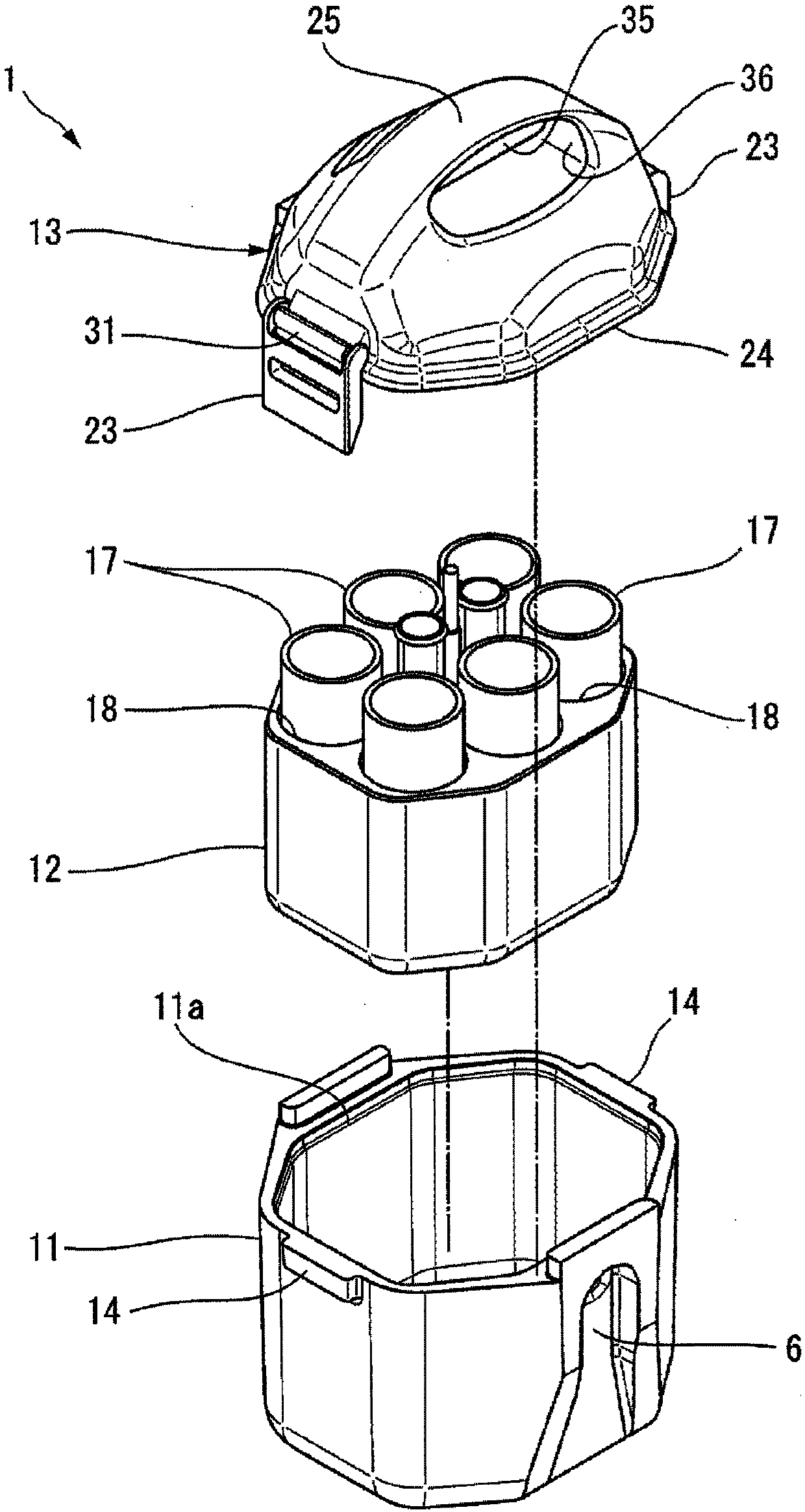

[0047] The following will refer to Figure 1 to Figure 12 An embodiment of a bucket for an oscillating rotor of a centrifuge according to the invention will be described in detail.

[0048] figure 1 The four barrels 1 shown in are supported by a rotor yoke 2 . The four buckets 1 and the rotor yoke 2 form an oscillating rotor 3 of a centrifuge (not shown). Rotor yoke 2 around figure 1 The axis of rotation indicated by the dashed-dotted line C1 in the center rotates. The axis of rotation C1 extends in the vertical direction.

[0049] Such as figure 2 As shown in , the rotor yoke 2 includes four arms 4 each extending in the horizontal direction. Each of the distal end portions of the arms 4 is provided with a trunnion pin 5 . The trunnion pins 5 support the tub 1 rotatably and detachably, and are each formed in a cylindrical shape. Trunnion pins 5 are rotatably fitted from below in trunnion pin grooves 6 provided in both side portions of each tub 1 (see figure 2 )middl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com