Roll-over type pineapple harvester

A harvester and pineapple technology, which is applied to harvesters, cutters, agricultural machinery and implements, can solve the problems of wasting manpower and material resources, and achieve the effects of efficient picking, simplified structure, and improved picking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described in detail below in conjunction with the accompanying drawings.

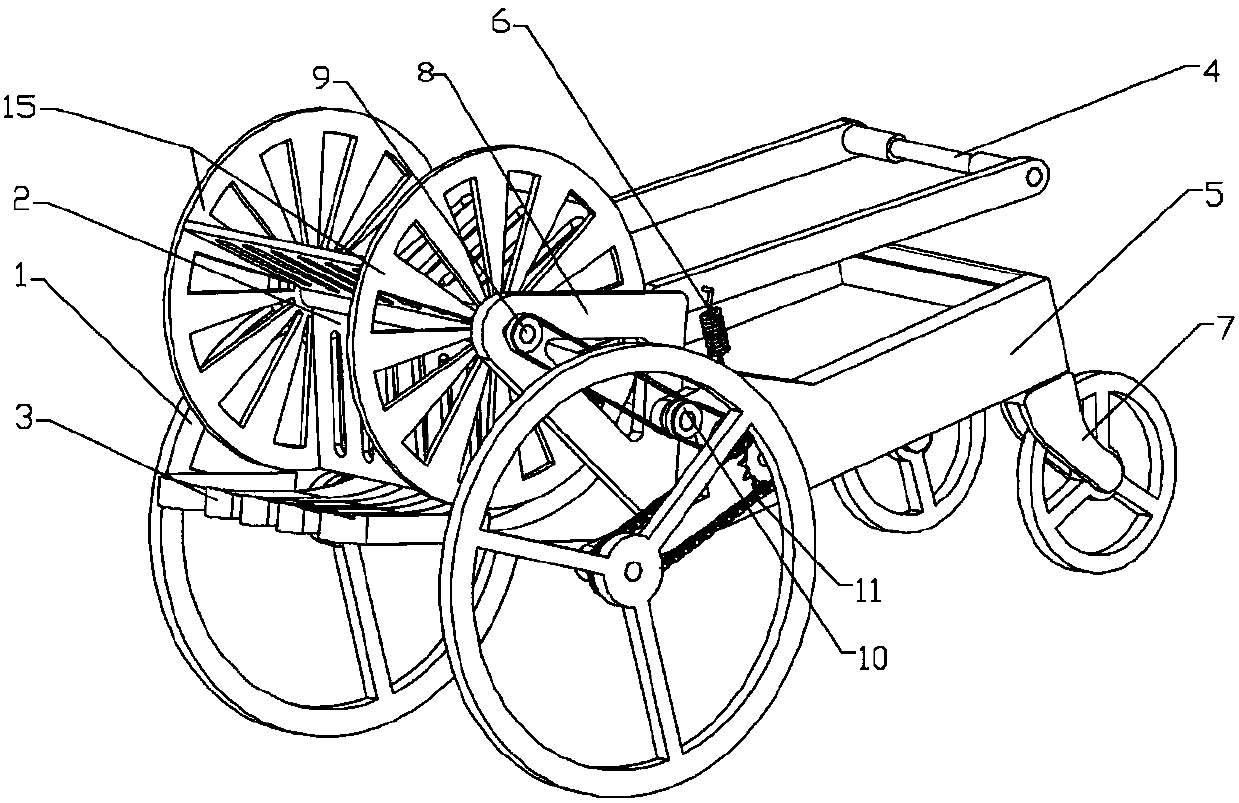

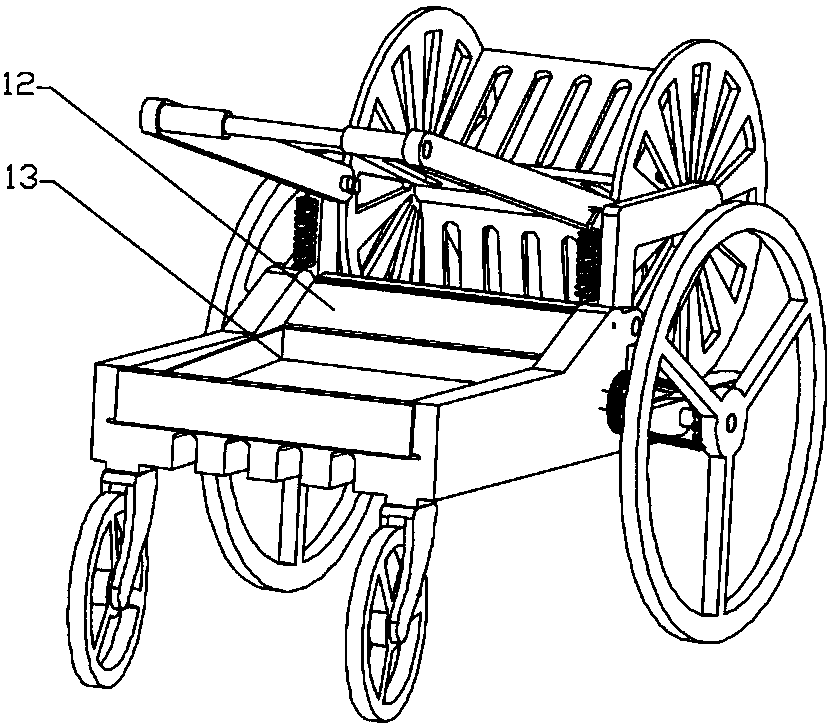

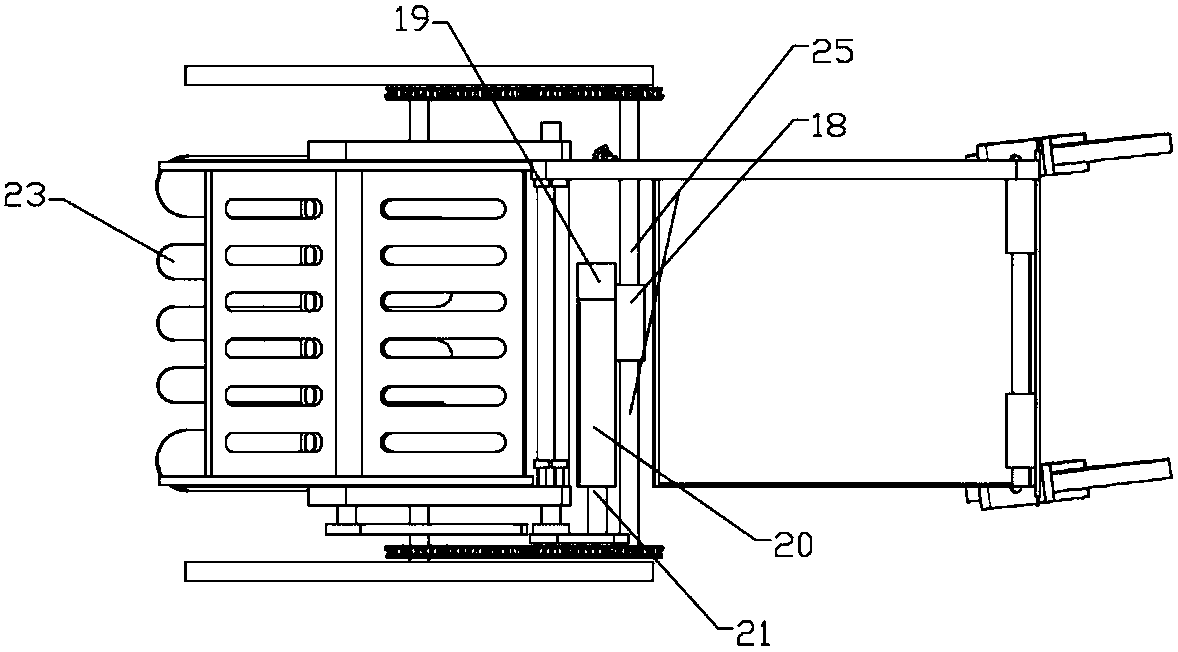

[0025] The tumbling pineapple harvester of the present invention can realize auxiliary manual picking of pineapples, such as figure 1 , figure 2 and image 3 As shown, the present invention includes picking parts, collecting parts, lifting parts, power transmission parts, supporting parts, wherein the picking parts are installed on the front end upper part of vehicle frame 5 and include scraper 2, separating frame 3 and scraper mounting frame 8, and collecting parts Including vehicle frame 5, chassis cover 12, collection box 13, lifting parts include control handle 4, scraper mounting frame 8 and the separation frame shaft 30 or hole on it, balance spring 6, power transmission parts include drive motor 19, a Into and out of two gearboxes 20, differential 18, front axle output shaft 25, scraper drive shaft 21, scraper shaft 9, scraper p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com