Highland-barley-kernel pie and preparing method thereof

A technology of highland barley and granules, applied in the field of highland barley granule pie and its preparation, can solve the problems of difficult absorption, rough taste of tsampa, etc., and achieve the effects of easy absorption, improved nutrition and digestion and absorption rate, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing highland barley granule pie, comprising the following steps:

[0035] Cake skin production steps: prepare ingredients according to the ratio of the cake skin, mix the mung bean paste and maltitol in the cake skin, add the eggs in two times, stir evenly, then add the cake skin custard powder, add the cake skin thickener, natural matcha Powder, after mixing evenly, let it stand for 3-7 minutes to get the cake skin, set aside;

[0036]Filling production steps: Prepare ingredients according to the filling ratio, mash the peeled potatoes, heat and cook until rotten, remove the surface moisture, transfer to a blender, add the filling mung bean paste, mash into a paste, add sugar, compound emulsifier , stir well, then pour it back into the pot, and boil; add maltitol, compound cream, and salt to the pot in turn, stir while adding, and cook until it forms a ball; make milk powder and filling custard powder into a paste, and divide it into three times Add...

Embodiment 1-7

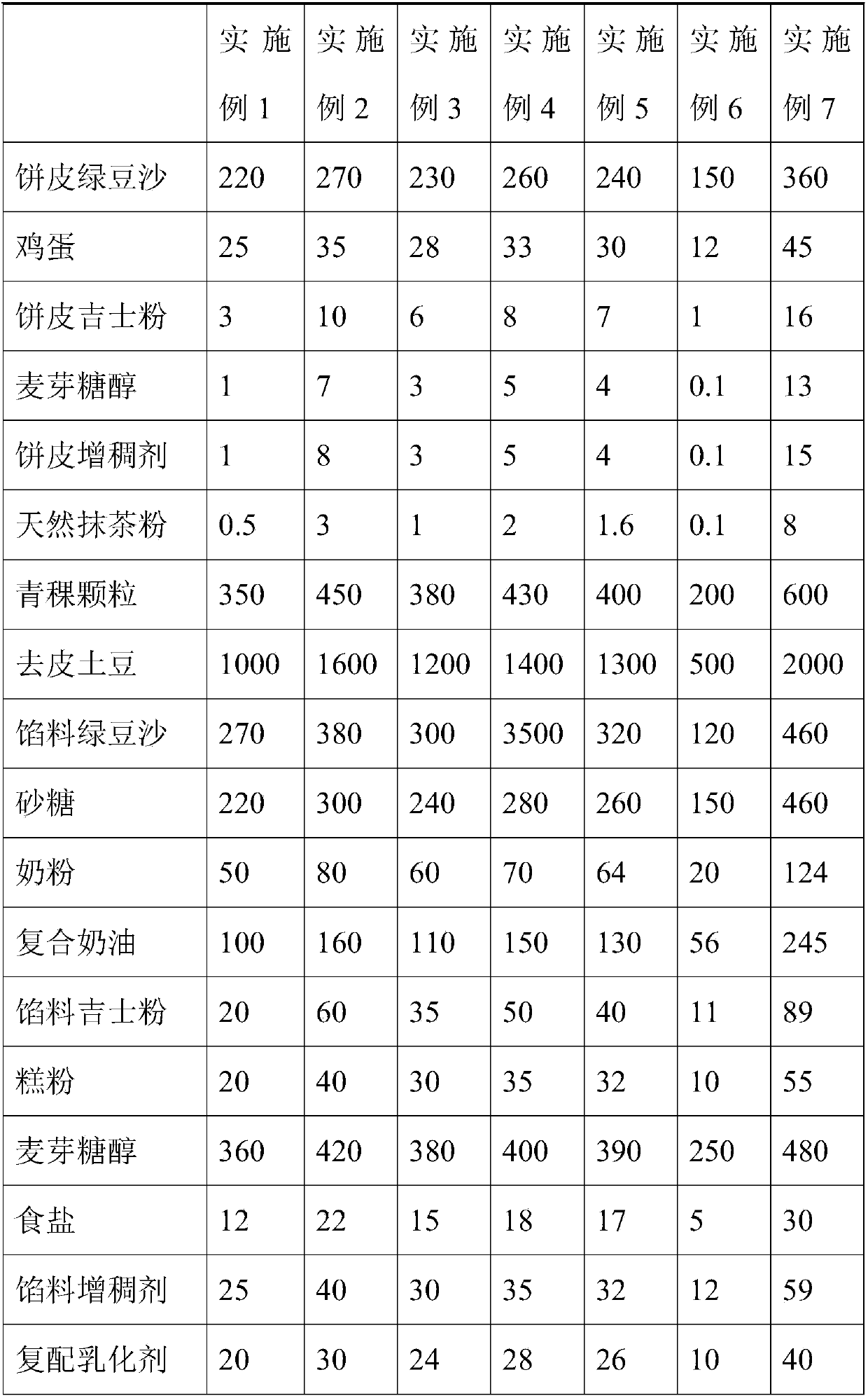

[0044] The proportioning ratio of Examples 1-7 is shown in the table below.

[0045] Table 1 Embodiment 1-7 proportioning

[0046]

[0047] The preparation method of the highland barley particle pie of embodiment 1-7 all adopts following method, and method comprises the following steps:

[0048] Cake skin production steps: prepare ingredients according to the ratio of the cake skin, mix the mung bean paste and maltitol in the cake skin, add the eggs in two times, stir evenly, then add the cake skin custard powder, add the cake skin thickener, natural matcha Powder, after mixing evenly, let it stand for 3-7 minutes to get the cake skin, set aside;

[0049] Filling production steps: Prepare ingredients according to the filling ratio, mash the peeled potatoes, heat and cook until rotten, remove the surface moisture, transfer to a blender, add the filling mung bean paste, mash into a paste, add sugar, compound emulsifier , stir well, then pour it back into the pot, and boil; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com