Separating-preventing ligating clip

A ligation clip and anti-dropping technology, which is applied in the field of medical devices, can solve the problems of vascular clips falling off, easily damaged and broken at the connection, and difficult to control the quality of the arc-shaped hole. Solid and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

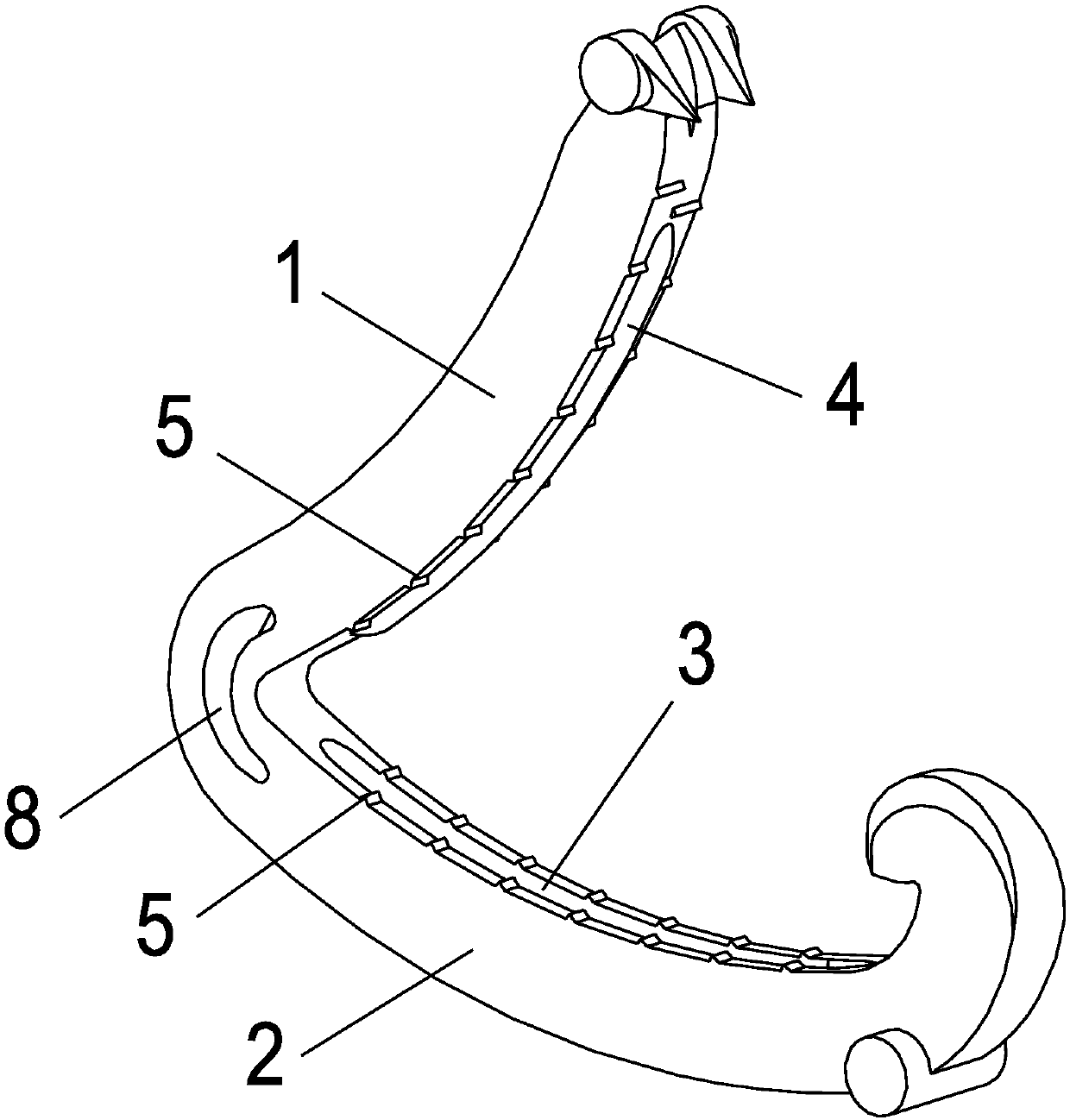

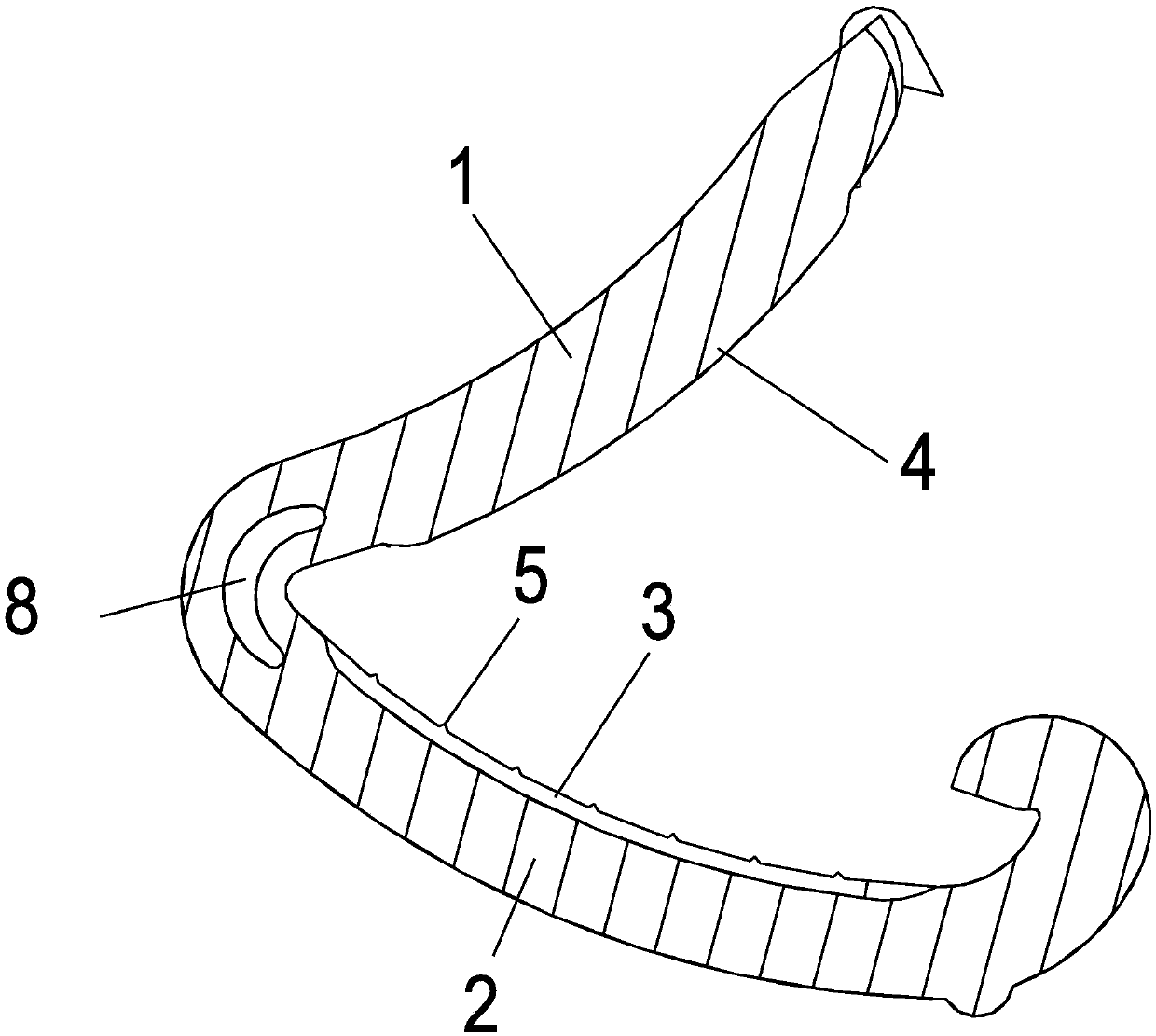

[0034] Such as Figure 1-3 As shown, the clamping surface of the upper clamping arm 1 is provided with an anti-slip protrusion 4 , and the clamping surface of the lower clamping arm 2 is provided with an anti-slip long groove 3 .

[0035] Preferably, the anti-slip long groove 3 is located in the middle of the clamping surface, the clamping surfaces on both sides of the anti-slip long groove 3 are provided with anti-slip lines 5, the anti-slip protrusion 4 is located in the middle of the clamping surface, and the two sides of the anti-slip protrusion 4 are clamped Anti-slip lines 5 are provided on the surface.

[0036] When the upper clamping arm 1 and the lower clamping arm 2 are clamped together, the anti-slip long groove 3 and the anti-slip protrusion 4 are buckled together, which not only increases the clamping area, but also makes the clamping tissue on different surfaces, which can effectively prevent the lateral slipping of blood vessels.

Embodiment 2

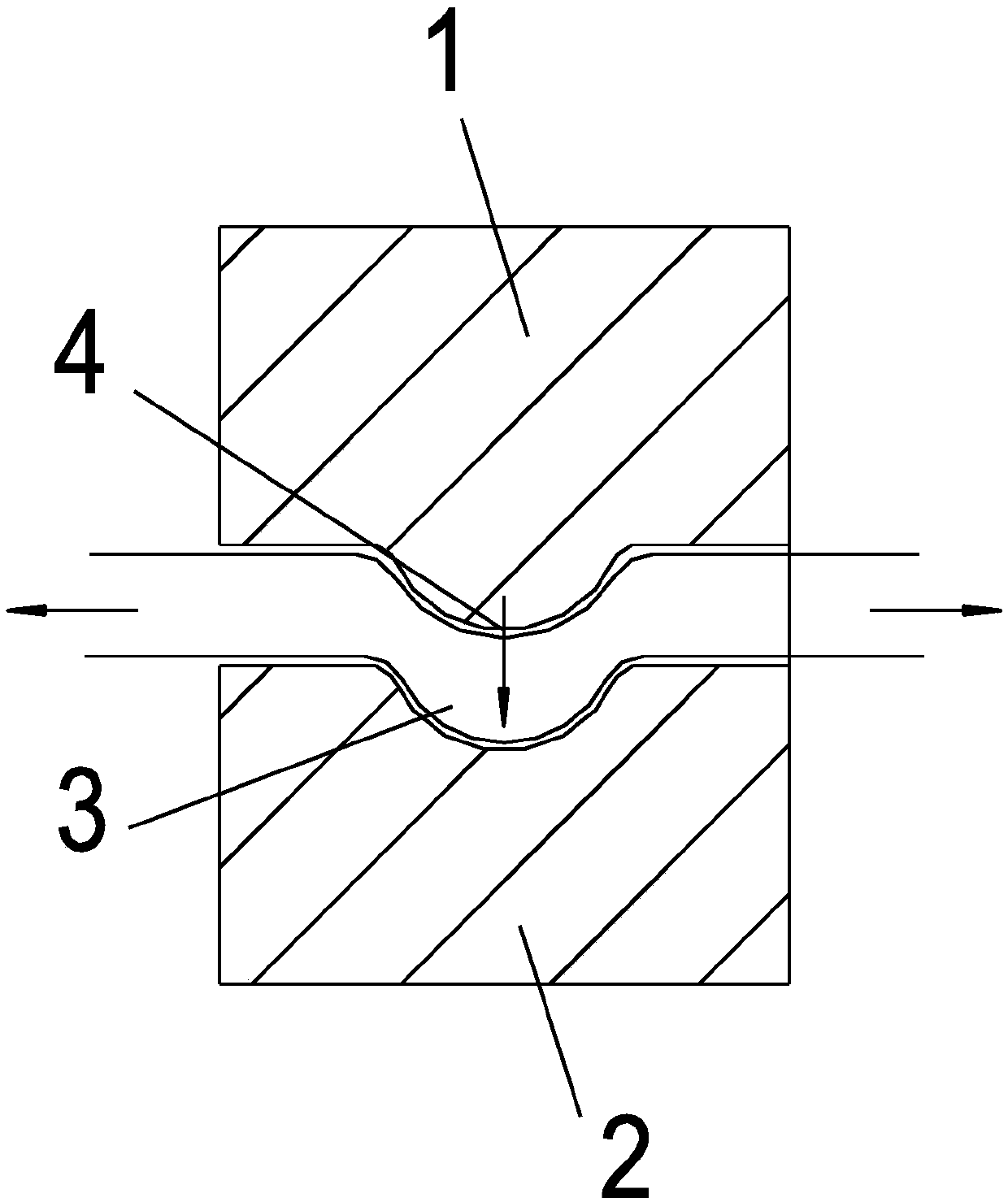

[0038] Such as Figure 4-6 As shown, the clamping surface of the upper clamping arm 1 is provided with an anti-slip long groove 3 , and the clamping surface of the lower clamping arm 2 is also provided with an anti-slip long groove 3 .

[0039] Preferably, the long anti-slip groove 3 is located in the middle of the clamping surface, and the two sides of the long anti-slip groove 3 are provided with anti-slip lines 5 on the clamping surface.

[0040] When the upper clamping arm 1 and the lower clamping arm 2 are clamped together, the two anti-skid long grooves 3 buckle to form an inner cavity. When clamping, the tissue expands in the inner cavity to form a lateral block, which can effectively increase the clamping force and prevent the blood vessel from slipping laterally.

Embodiment 3

[0042] Such as Figure 11-12 As shown, the anti-slip long groove 3 is provided with one, which extends from the front side of the clamping surface of the clamp arm to the rear side; the corresponding anti-slip protrusion 4 is also provided with one, which extends from the front side of the clamping surface of the clamp arm to the rear side. rear side.

[0043] Described upper jig arm 1 and lower jig arm 2, wherein one is wide arm 9, and another is narrow arm 10; Anti-slip long groove 3 is set on wide arm 9, and anti-slip protrusion 4 (anti-slip protrusion 4 is set on narrow arm 10) Consistent with the width of the clamping surface of the narrow arm 10). The upper side of the narrow arm 10 is embedded in the anti-skid slot 3 of the wide arm 9 .

[0044] Chamfers 6 are provided on both sides of the clamping surface of the narrow arm 10 , and both inner surfaces of the long anti-slip groove 3 are inclined surfaces 7 matching with the chamfers 6 .

[0045] The bottom surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com