Eddy current air inflow type nozzle for spraying release agent

A type of release agent and air-intake technology, which is applied in the direction of injection devices and liquid injection devices, can solve the problems of long response time of nozzle opening and closing, excessive disturbance of release agent liquid, etc., achieve good response time, reduce pollution, and save energy. The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

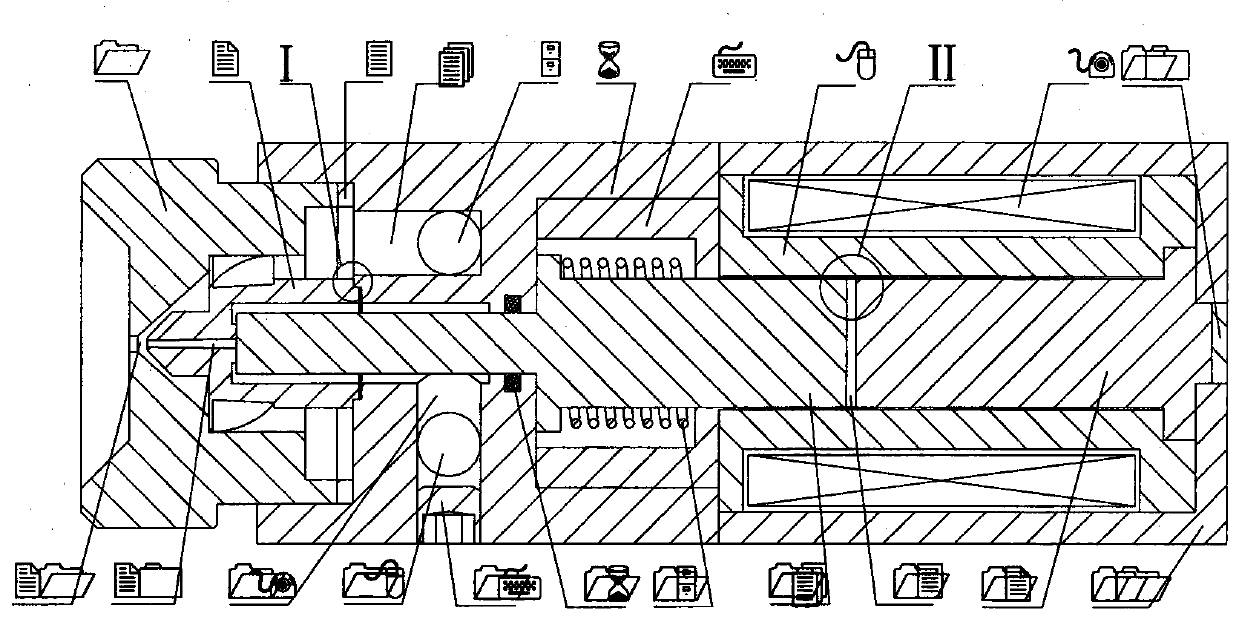

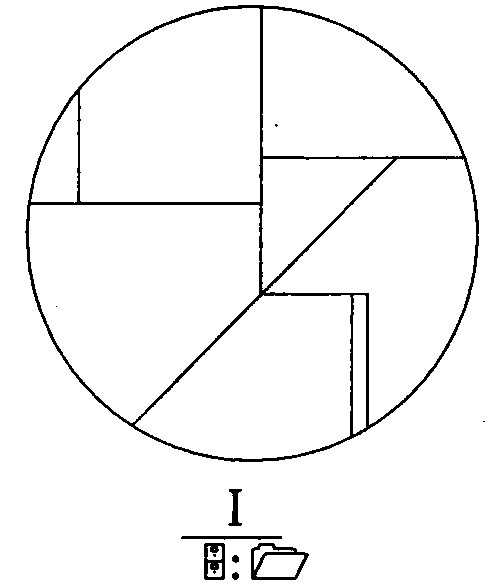

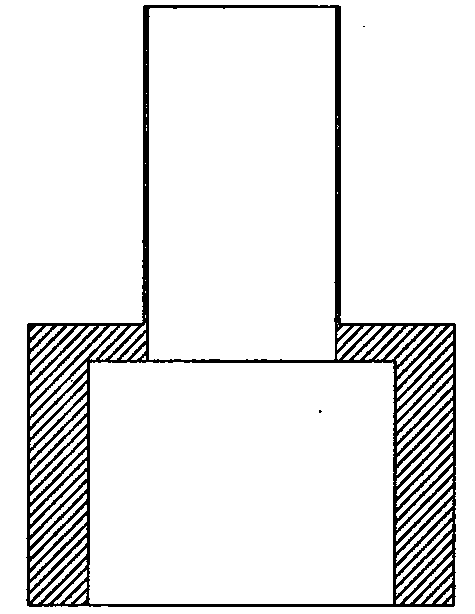

[0032] The present invention is a nozzle for spraying of a vortex air intake type release agent, such as figure 1 As shown, it consists of nozzle cover 1, atomizing head 2, gasket 3, front valve body 6, guide sleeve 7, coil skeleton 8, coil 9, sealing cover 10, rear shell 11, static iron core 12, moving iron core 14. Spring 15, sealing ring 16, set screw 17 and other components. The atomizing head 2 is arranged inside the nozzle cover 1, and the nozzle cover 1 and the front valve body 6 are connected by threads, and the atomizing head 2 is clamped between the nozzle cover 1 and the front valve body 6, as figure 2 shown. The spool of the nozzle part and the armature of the electromagnetic control part are made into a whole, that is, the moving iron core 14 . The front section of the moving iron core 14 is arranged inside the atomizing head 2 , the middle section of the moving iron core 14 passes through the front valve body 6 , and the rear section of the moving iron core 14...

Embodiment 2

[0040] In this embodiment, three evenly distributed spiral channels 28 are provided on the outside of the atomizing head 2 . Others are the same as the embodiment.

Embodiment 3

[0042]In this embodiment, six evenly distributed spiral channels 28 are provided on the outside of the atomizing head 2 . Others are the same as the embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com