A drum sorting screen

A drum-type, sorting and screening technology, applied in the field of sorting and screening, can solve the problems of easy clogging of the screen, reduced support of the screen, and depression.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

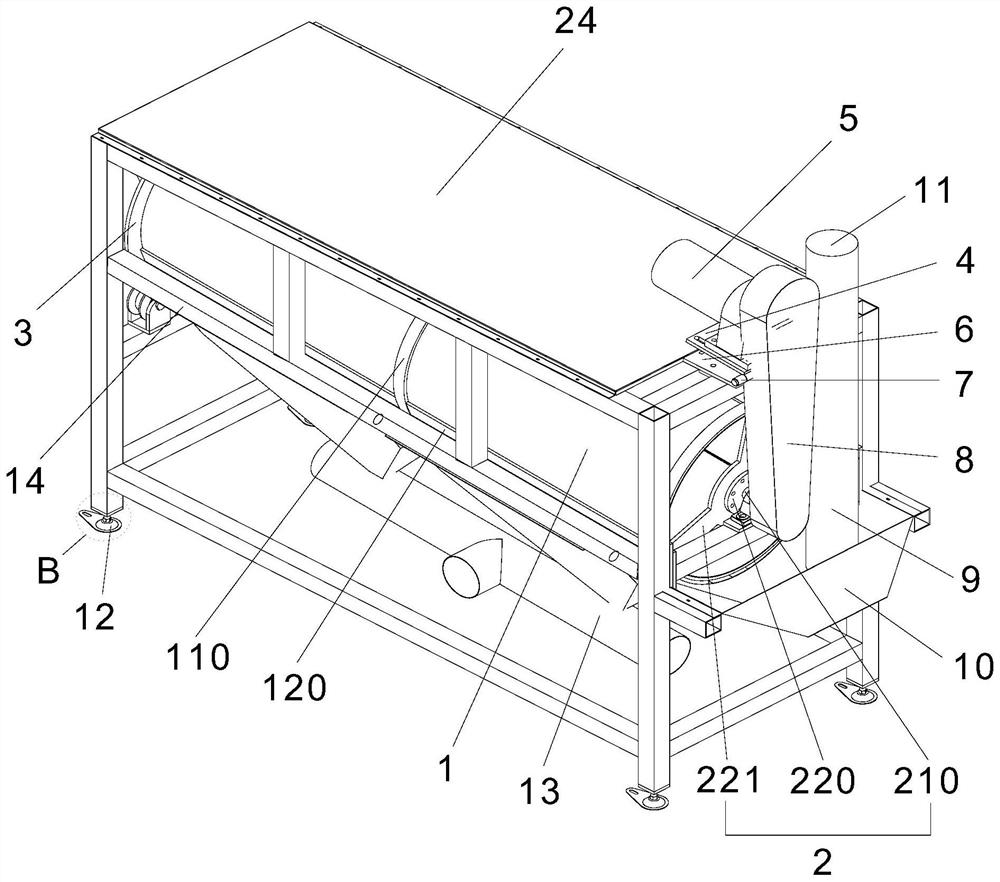

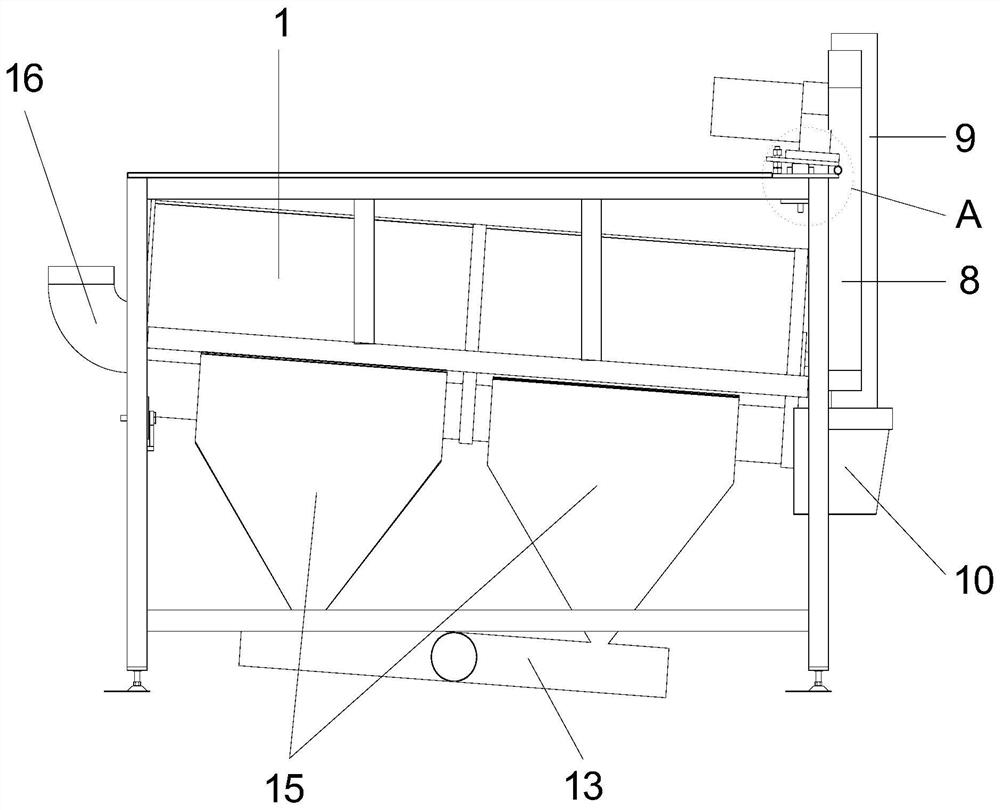

[0033] see figure 1 —3, a kind of drum type sorting screen, it comprises: frame 14, drum type screen cloth 1 is installed on frame 14, and drum type screen cloth 1 is inclined at a certain angle with the horizontal plane; Drive wheel 2, It includes a rotating shaft 210 and a hub 220 sleeved on the rotating shaft 210; the hub 220 includes several hub brackets 210; the follower wheel 3, in order to reduce the resistance of the follower wheel 3 running, the frame 14 is connected with a pulley bracket 22, The pulley bracket 22 is connected with a pulley 21, and the follower wheel 3 is arranged on the pulley 21; the beam 120 is fixedly connected to a hub support 4 at one end, and fixedly connected to the follower wheel 3 at the other end; 210 are arranged in parallel; the motor 5 is arranged on the support 4 and is fixedly connected with the support 4, and the motor 5 drives the driving wheel 2 to run through the transmission belt. For the sake of safety, a protective baffle 8 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com