Cutting device of iron wire feather duster handle

A cutting device and a technology for a hair duster, which are applied to the field of cutting devices for a wire brush handle, can solve the problems of time-consuming and labor-intensive, low production efficiency, insufficient automation, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

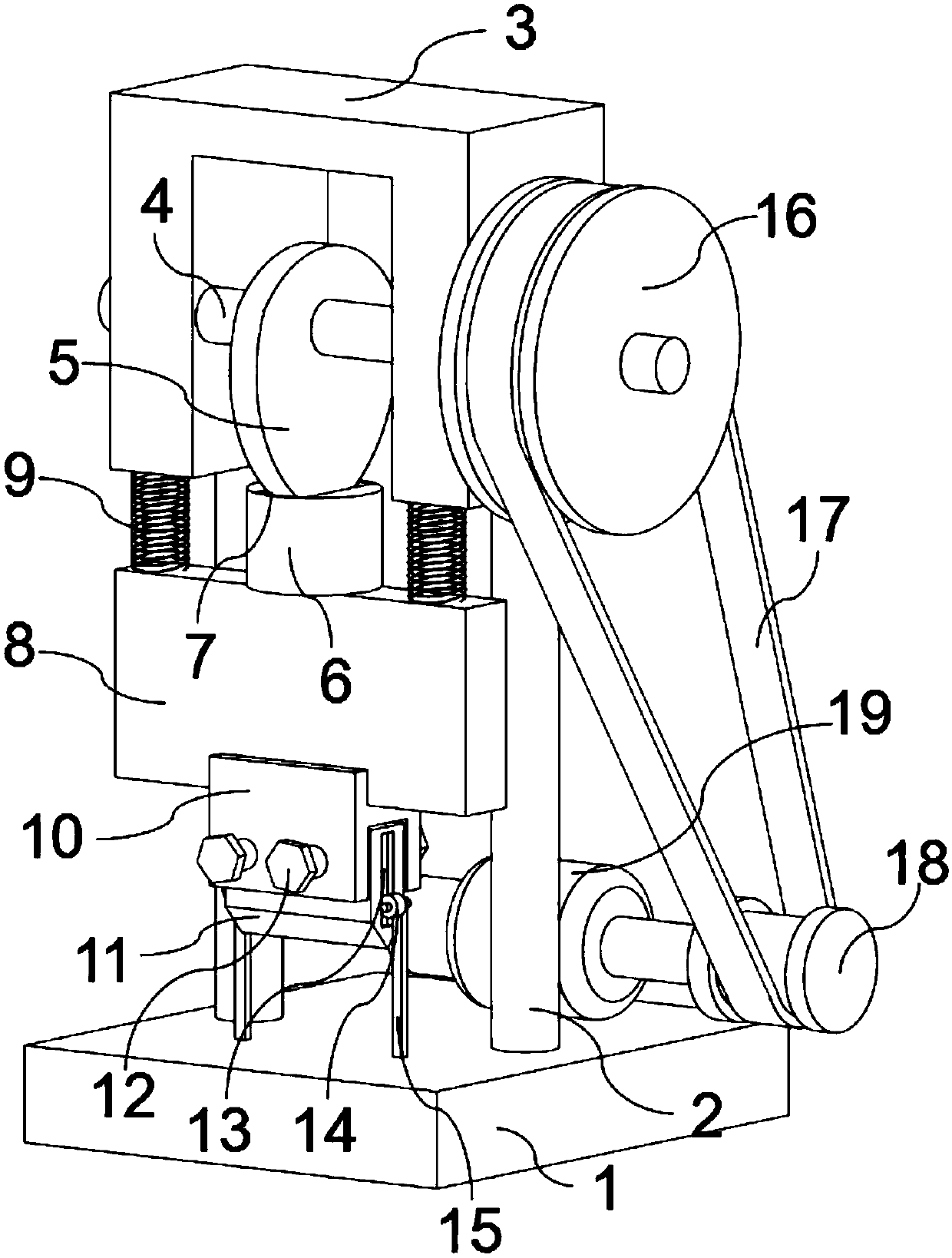

[0021] like figure 1 As shown in the three-dimensional structure diagram of the wire wool duster handle cutting device, a wire wool duster handle cutting device includes a base 1, a support rod 2 is arranged on the base 1, and a support frame 3 is fixed on the upper end of the support rod 2. The support frame 3 is equipped with a rotating shaft 4, the rotating shaft 4 is provided with a cam 5, and the cam 5 can rotate in the cam track 7 of the cam support shaft 6, and the cam support shaft 6 is fixed on the support plate 8, so A strong spring 9 is installed between the support plate 8 and the support frame 3, a cutter holder 10 is installed below the support plate 8, a cutter 11 is housed on the cutter holder 10, and the cutter 11 is fixed by Screw 12 is fixed, and described cutter 11 two sides are provided with cutter moving groove 13, and described cutter moving groove 13 links to each other with roller 14, and described roller 14 is installed on the roller support bar 15, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com