Automatic assembling machine for slide rail

A technology for assembly machines and slide rails, applied in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as poor product quality, high production costs, and poor assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

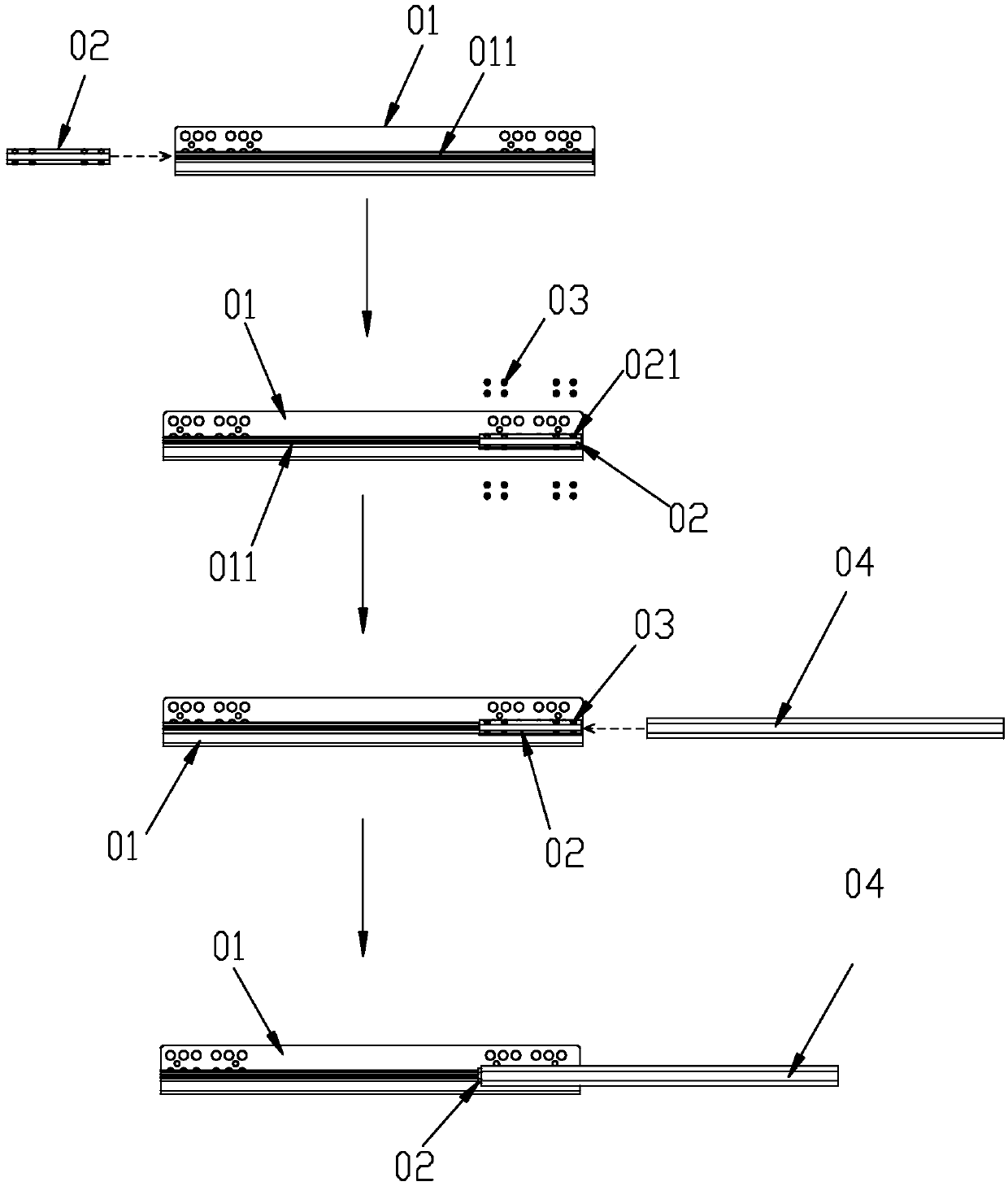

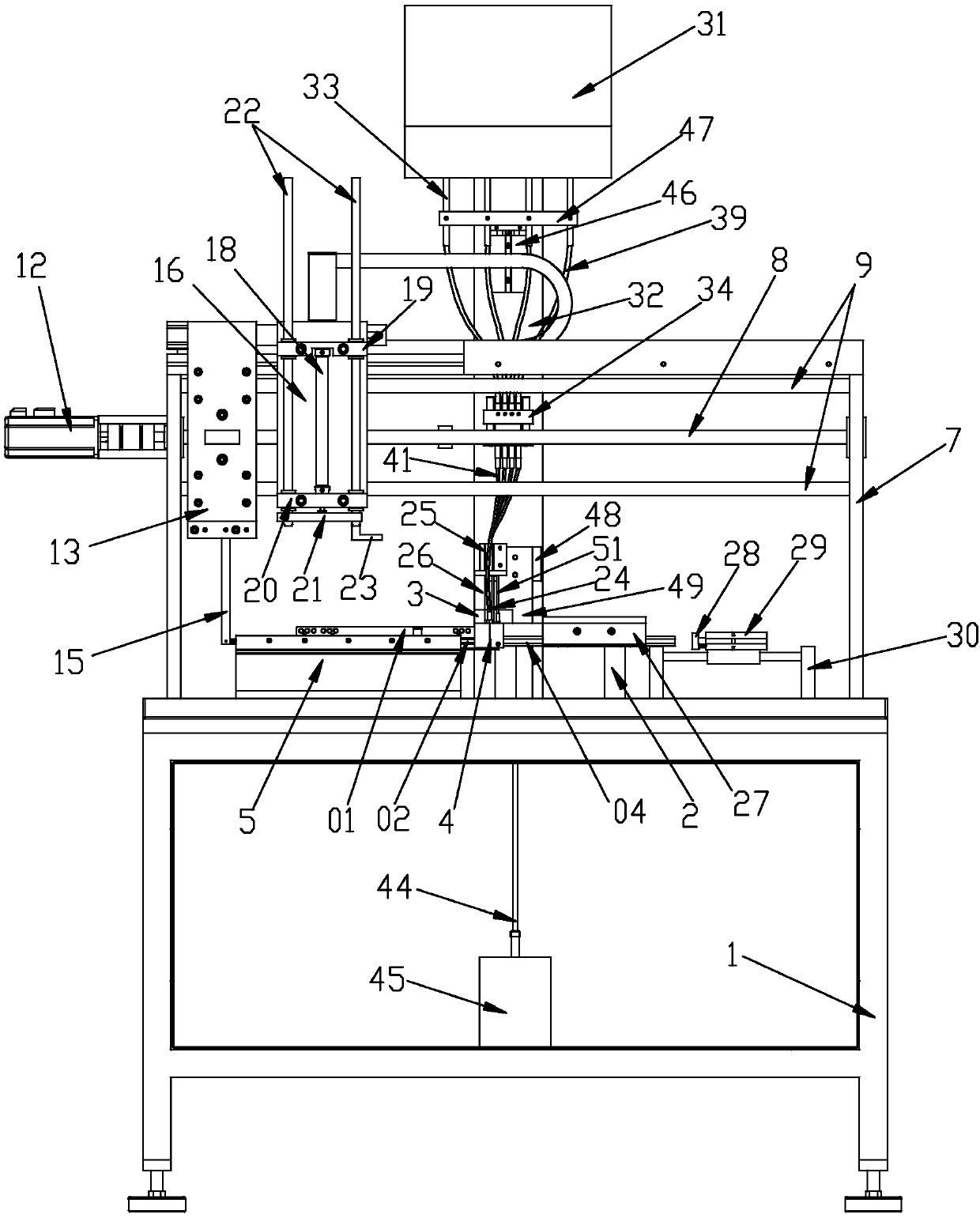

[0045] refer to Figure 2-16 :

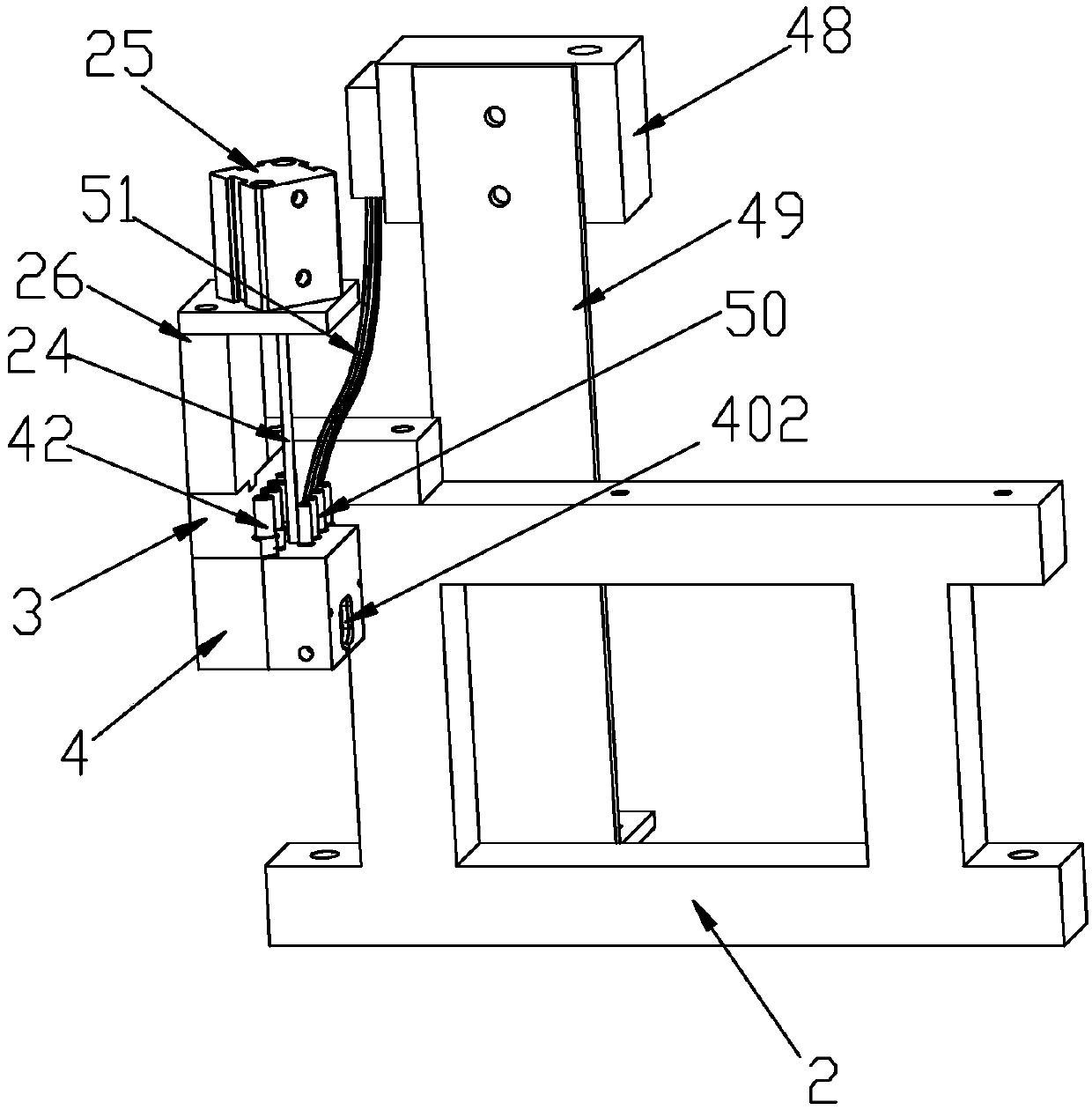

[0046] An automatic assembly machine for slide rails, comprising a machine platform 1, an underframe 2 is provided on the table surface of the machine platform, a cross arm 3 is provided on the front end of the underframe 2, and an assembly seat 4 is fixedly installed on the bottom surface of the cross arm 3. The bottom surface of the seat 4 is provided with a bracket U-groove 401 and a movable rail U-groove 402 for the slide rail bracket 02 and the movable rail 04 to be inserted from the left and right sides of the left and right sides, and the movable rail U-groove 402 is arranged vertically. The bottom outlets of the ball through holes 403 and the four ball guide holes 403 communicate with the U-groove 401 of the bracket, and are located at positions that can be connected with each group of ball mounting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com