Bar feeding device

A technology of discharging device and bar material, which is applied in the direction of grinding machine, metal processing equipment, grinding/polishing equipment, etc. The effect of high efficiency, improved processing quality and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

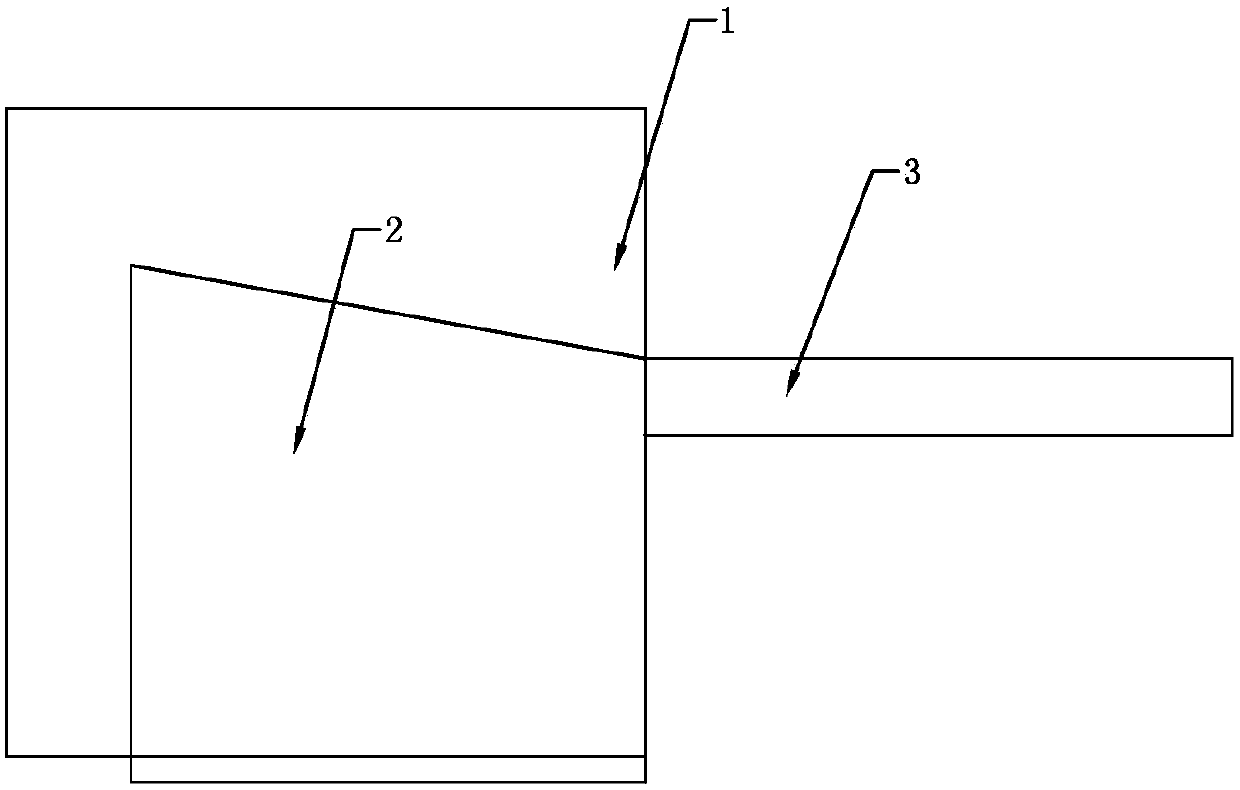

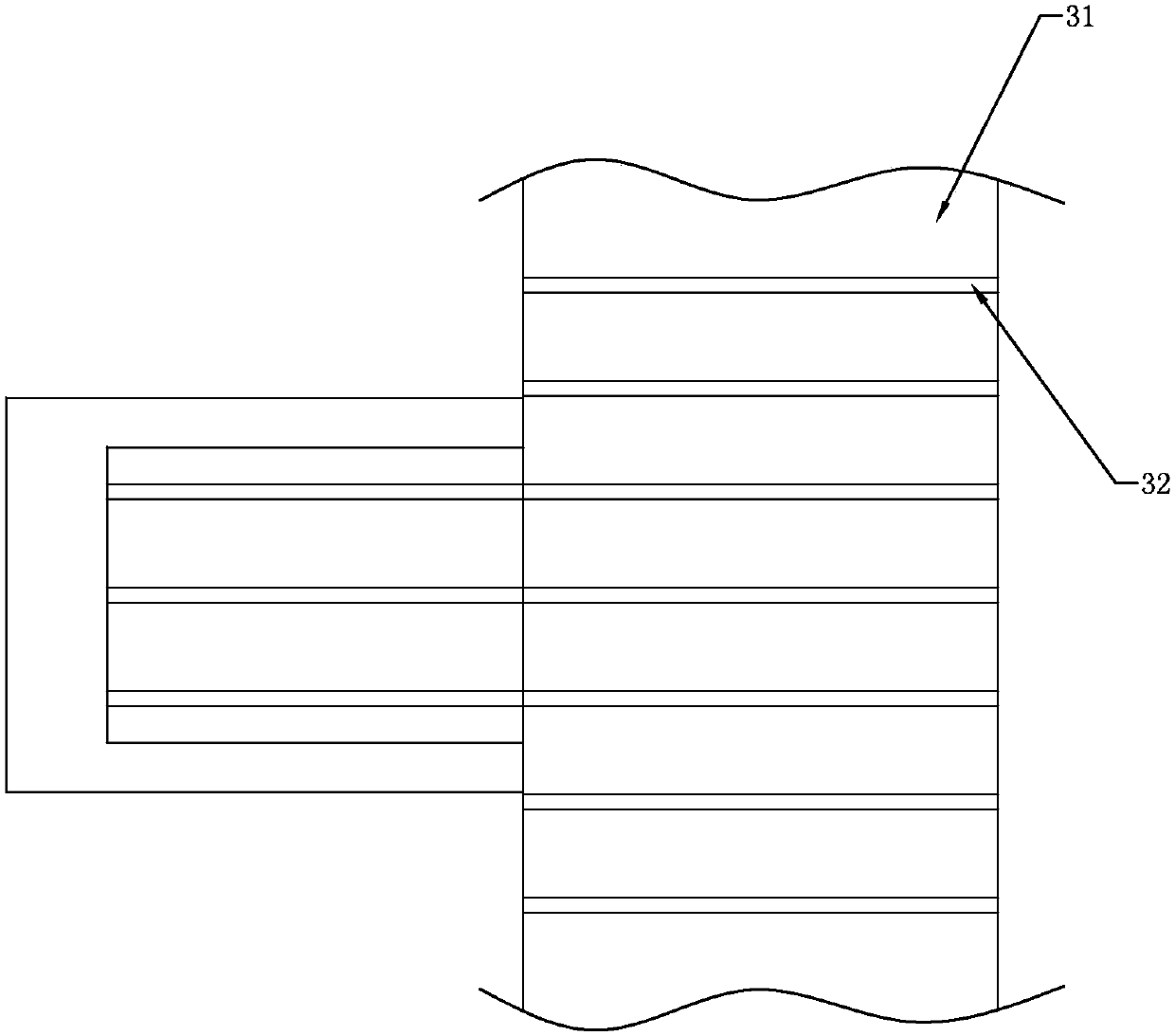

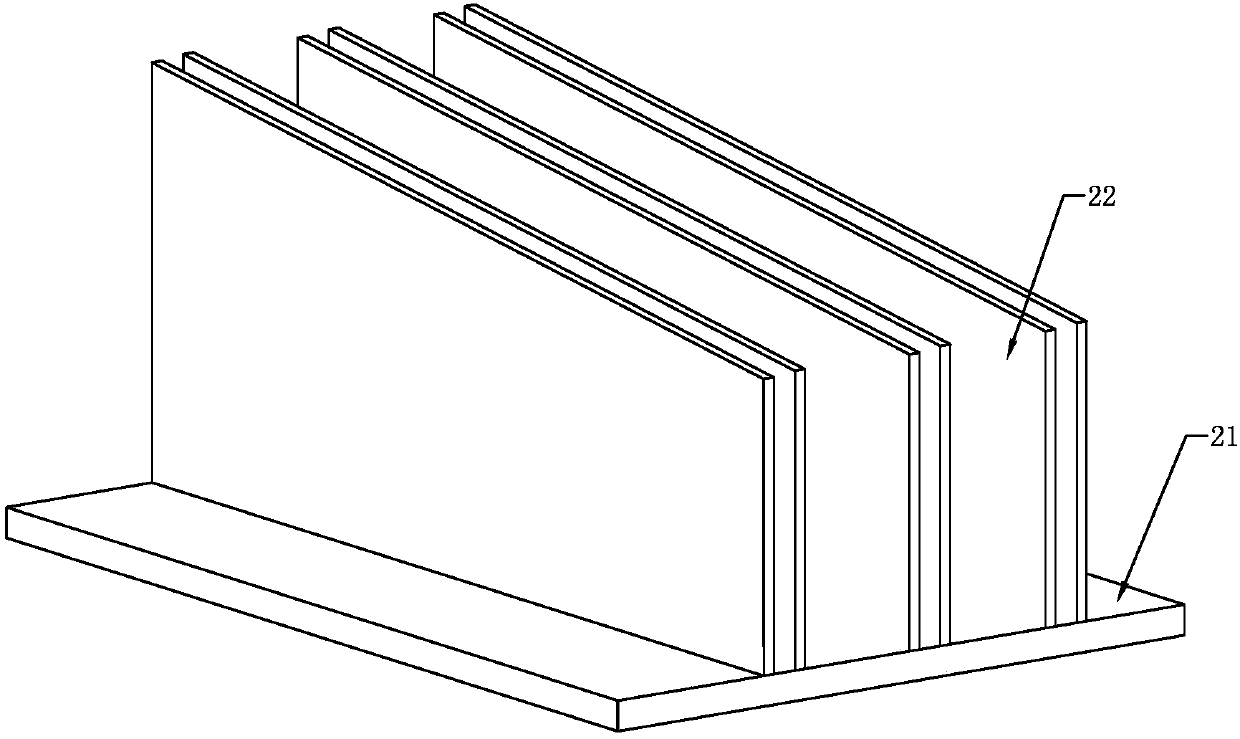

[0015] refer to Figure 1 to Figure 3 , a bar feeding device of the present invention includes a material box 1, a lifting device 2 and a discharge device 3, the length of the material box 1 is adapted to the length of the bar, and the lifting device 2 includes a bottom plate 21, a top block 22 and a power unit, the top block 22 includes two side-by-side inclined plates, the top edge of the inclined plates is a hypotenuse, the gap between the two inclined plates is less than the diameter of the bar, and the top block 22 is fixedly arranged on the bottom plate 21, the bottom plate 21 is arranged below the material box 1, and the top block 22 extends into the material box 1 through the strip hole at the bottom of the material box 1, and the power device can drive the bottom plate 21 and the top block 22 to rise and fall. A through hole is opened at the highest position corresponding to the top block 22 in the magazine 1, the size of the through hole is adapted to the size of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com