Dual-feedback compact type high-precision hollow integrated joint

A compact, high-precision technology, applied in the control of mechanical energy, joints, manipulators, etc., can solve problems such as wounding, leakage, and joints that are not smooth enough to achieve the effect of maintaining function, simple connection method, and smooth external curve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

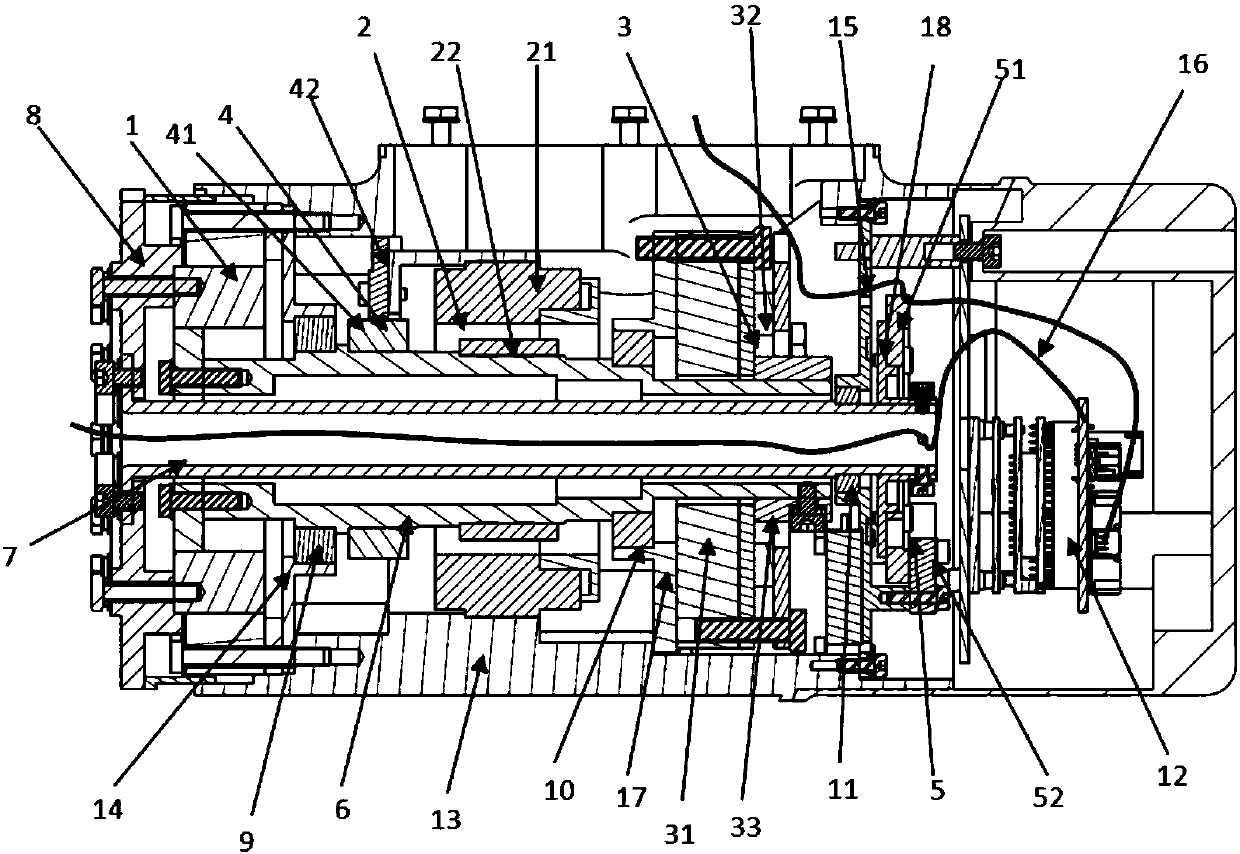

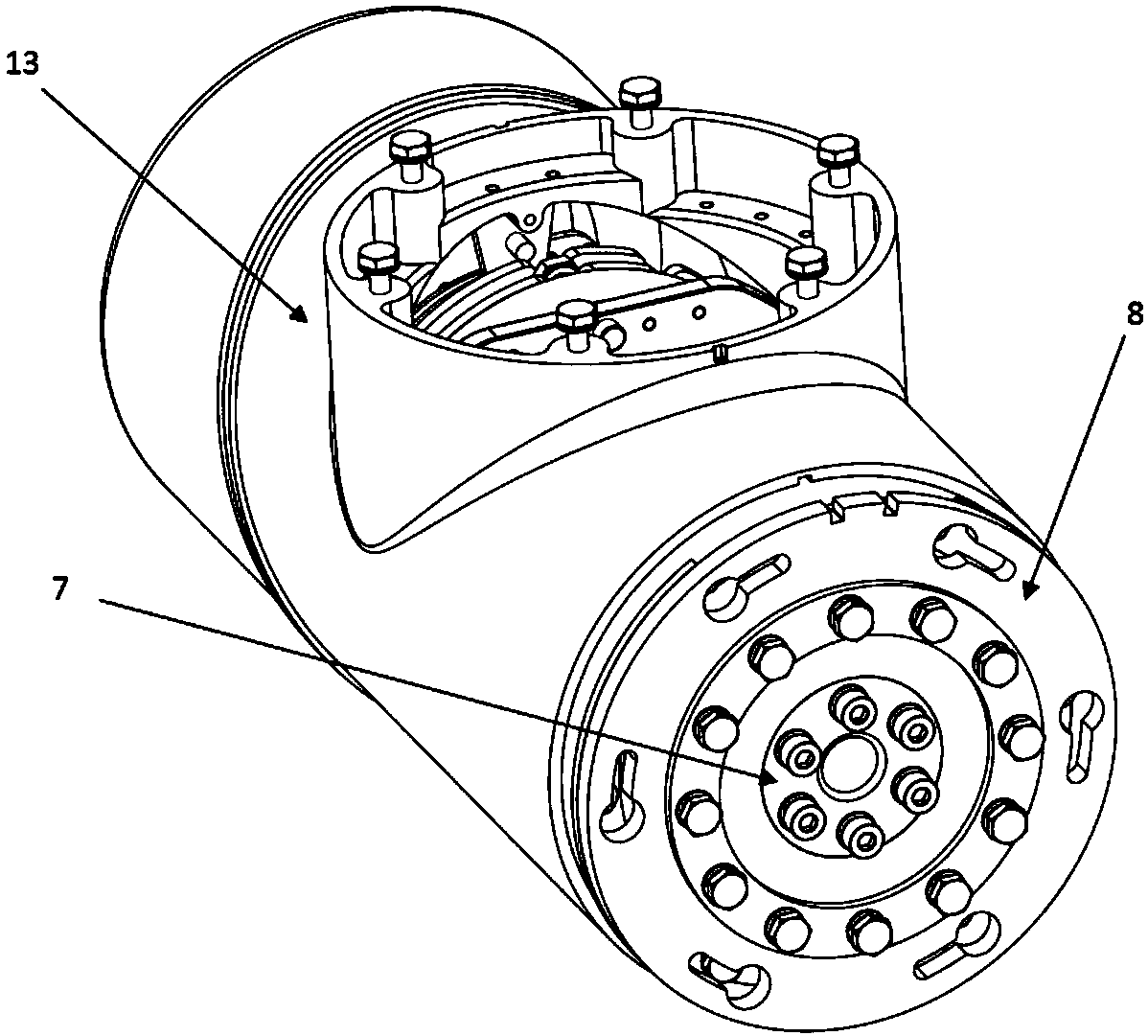

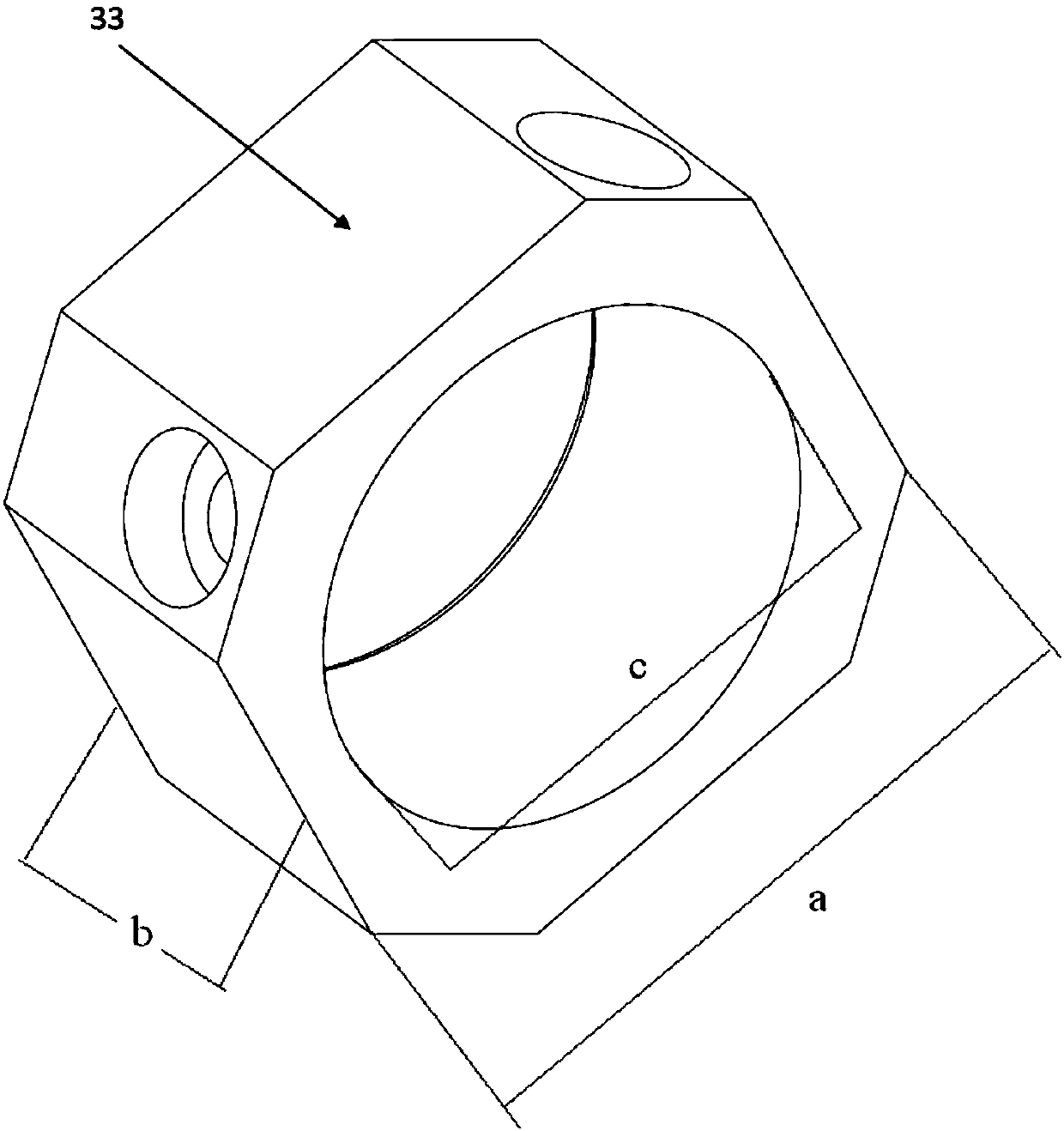

[0038]The rotor hub 33 has a square structure with a through hole in the center, and is fixed on the side by screws with the high-speed motor shaft 6. The side length a of the rotor hub 33 is 25 mm, the height b is 12.5 mm, the inner diameter c is 20 mm, and the four corners are flattened. The two corners have two countersunk holes for screw connection, the material is stainless steel 2Cr13. The frameless motor 2 uses Kollmorgen TBMS-6013-A, the gap between the motor stator 21 and the motor rotor 22 is 0.5mm, and the motor stator 21 and the motor rotor 22 are respectively glued to the housing 13 with thread glue Loctite 640 And on the high-speed motor shaft 6, the harmonic reducer is SHD-17-100-2SH, the motor shaft bearings 9, 10, and the hollow shaft bearing 11 are deep groove ball bearings. The brake stator 31 and the brake rotor 32 are Miki BXR-050-10LE.

[0039] The invention has high control precision, hollow joints, high integration, light weight, and reliable non-excit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com