Method for enhancing anticorrosion time of acid washing lens

A pickling lens and anti-corrosion technology, applied in the direction of chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problems of affecting the normal use of the lens, blackening, blackening of the coating, etc. Corrosion time, improve service life, delay corrosion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0015] A method for enhancing the anti-corrosion time of pickling lenses, comprising the following steps:

[0016] S1, first wash the semi-finished lens after the pickling process with clean water, dry or air-dry for later use;

[0017] S2, affix a protective film for preventing the mirror surface from being scratched on the side of the mirror surface of the semi-finished lens product treated in S1, and paste a layer of process film on the back side of the semi-finished lens product;

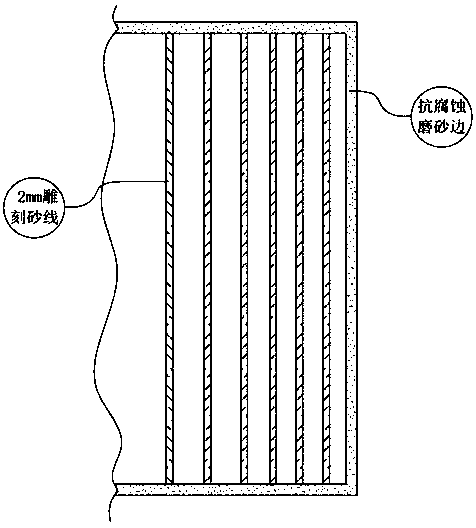

[0018] S3, use a vertical engraving machine to engrave the semi-finished lens that has been processed by S2, and engrave a 2mm wide sand line on the edge of the pickled lens;

[0019] S4, sanding the sand line engraved on the edge of the lens in S3, after the sanding is completed, remove the protective film on the mirror surface and the process film on the back, clean the semi-finished lens, and then dry or air dry it;

[0020] S5, pasting a layer of protective film on the mirror surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com