Measurement device and method used for screen printing machine and stencil printing machine

A technology of stencil printing machine and screen printing machine, which is applied to the general parts of printing machinery, printing machines, printing, etc., and can solve the problems of unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

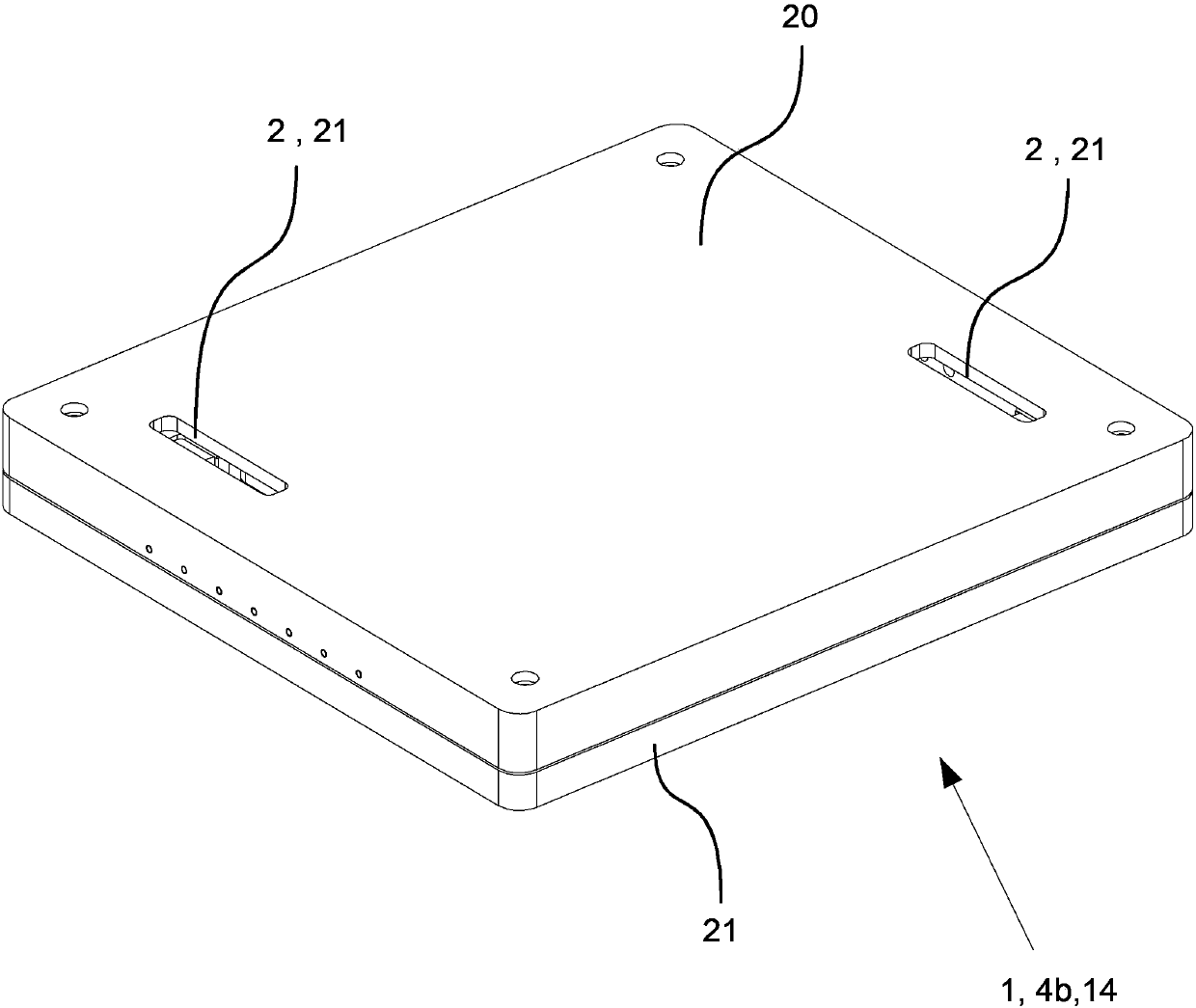

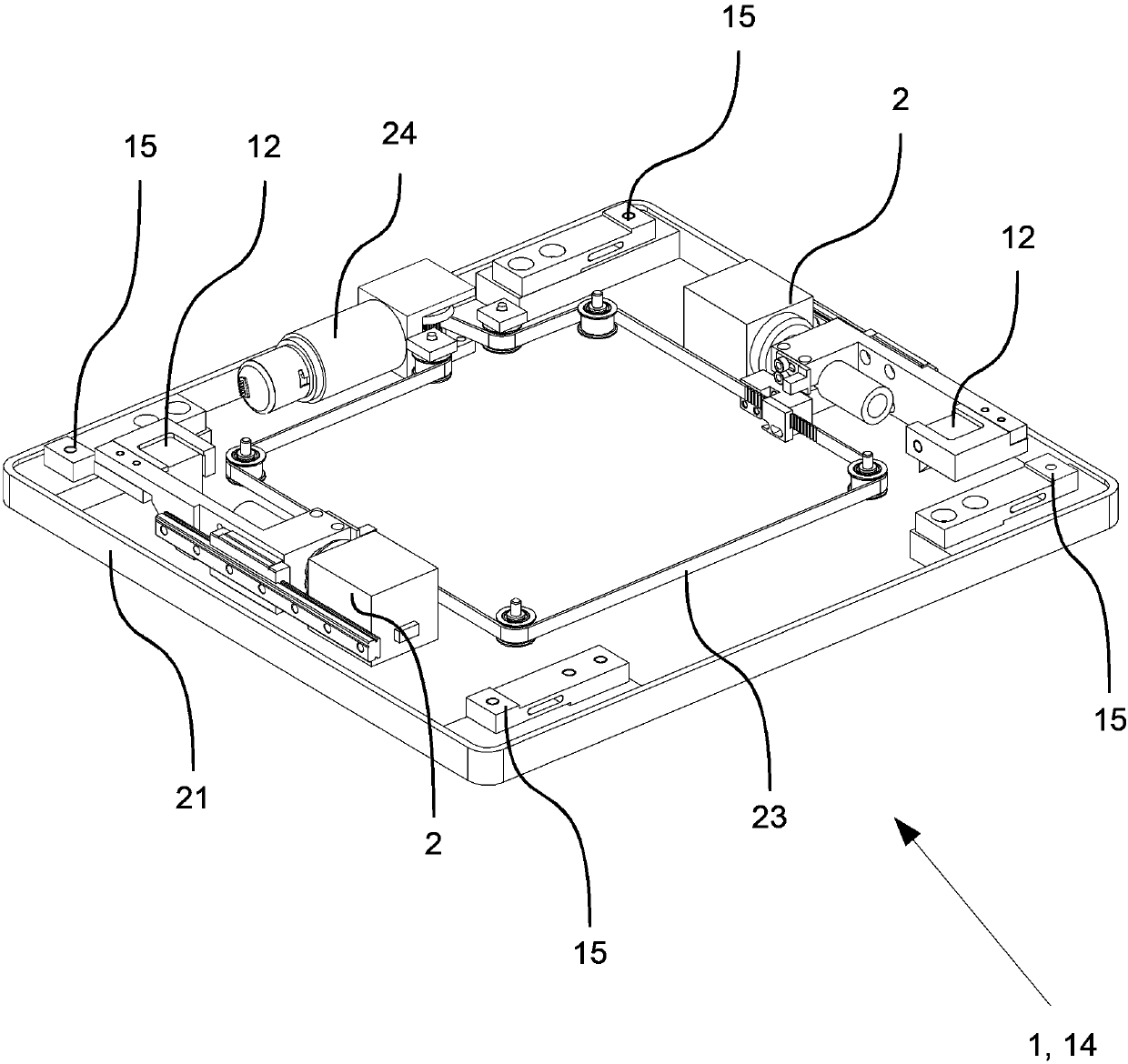

[0039] figure 1 A light transmission is shown of a measuring device 1 integrated in a force measuring plate 14 comprising two camera units 2 for use in a screen printing machine or a stencil printing machine (not shown).

[0040] In principle, it is advantageous that the measuring device 1 can be integrated in the plate-shaped wiring carrier receptacle 4b. In order to be able to use the assembly and at the same time also determine the scraper pressure, the optical measuring device 2 is integrated in the force-measuring plate 14 serving as the wiring carrier support 4 b.

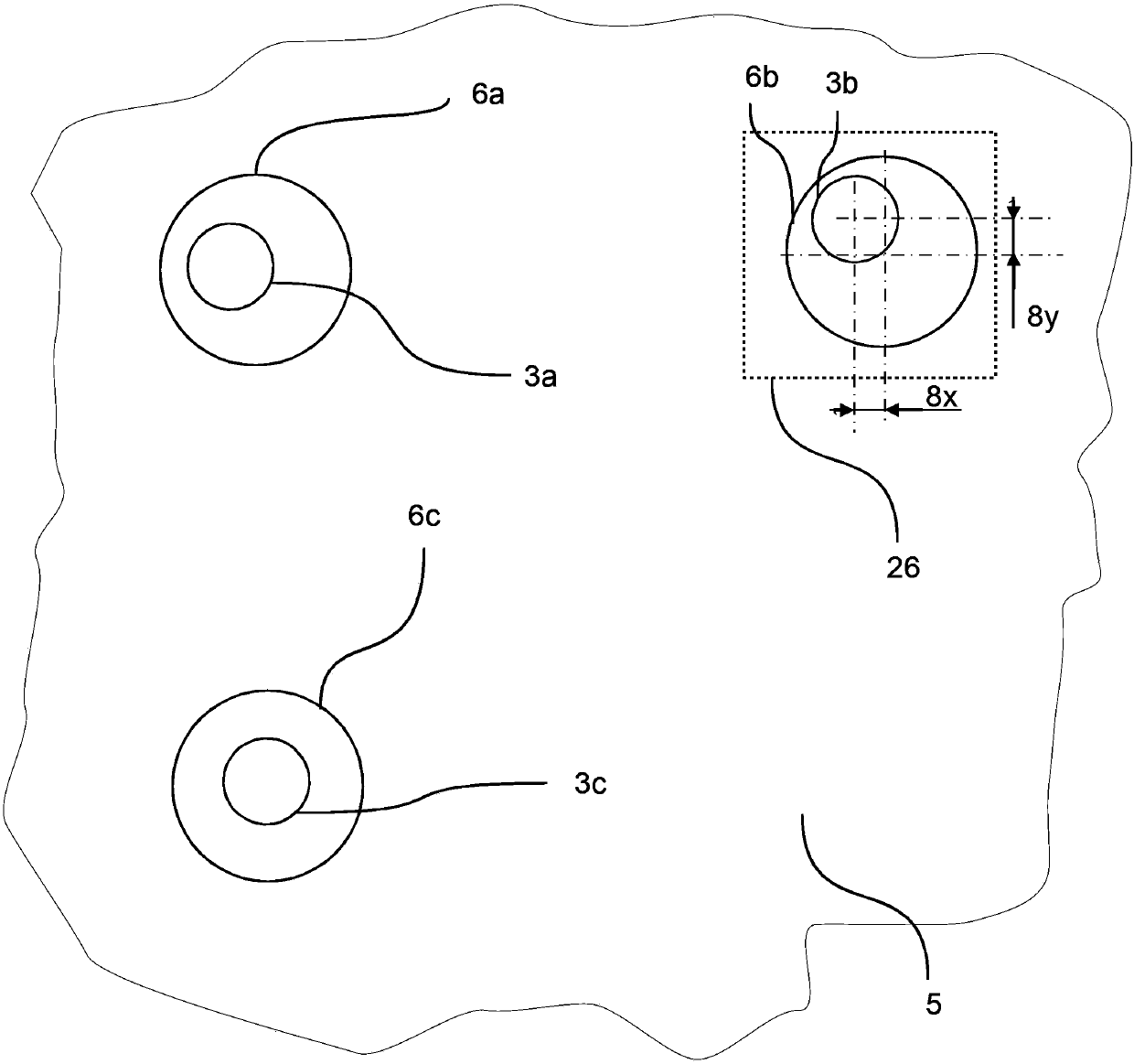

[0041] In the force measuring plate 14, between the cover plate 20 and the base plate 21, the force sensor 15 (in the figure 1 not shown). Optical measuring device 2 includes two camera units 2 arranged in measuring device 1 . For this purpose, corresponding openings 22 are provided in the cover plate 20 of the measuring device 1, said openings enabling the optical detection of the glass measuring plate ly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap