Method for adjusting rigidity of axle box positioning node with sectioning jackets and axle box positioning node

A technology of positioning nodes and adjustment methods, which is applied in the directions of axle box installation, railway car body parts, bogies, etc., can solve the problem of the large range of rigidity requirements of axle box positioning nodes in all directions, and achieves expansion of the scope of use and adjustable range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

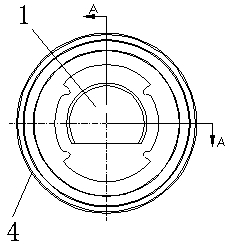

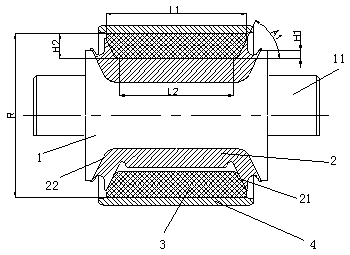

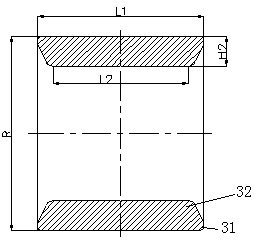

[0041] like Figure 1-Figure 3 As shown, a split casing 3-axle box positioning node includes a mandrel 1, a rubber layer 2, a split casing 3, and an overall casing 4. The rubber layer 2 is vulcanized and bonded on the outside of the mandrel 1, and the split casing 3 is set On the outside of the rubber layer 2, the overall jacket 4 is arranged on the outside of the split jacket 3; wherein the split jacket 3 is a circular sleeve that is divided into multiple pieces and has the same specifications in pairs, and includes a main body 1 31 positioned on the outside and a 31 positioned on the inside. Main body 2 32, main body 1 31 is a hollow cylinder inside, main body 2 32 is a circular cylinder with internal hollow and concave slopes at both ends, the outer side of main body 2 32 and the inner side of main body 1 31 are connected as a whole .

[0042] like figure 2 and image 3 As shown, the thickness H2 of the split coat 3, the length L1 of the split coat 3 main body one 31, t...

Embodiment 2

[0053] This embodiment is basically the same as Embodiment 1, the difference is that: Figure 4 and 5 As shown, between the thickness H2 of the split coat 3, the length L1 of the split coat 3 main body one 31, the length L2 of the split coat 3 main body two 32 inner sides and the inclined plane and the inner side of the split coat 3 main body two 32 two ends The relationship between the angle A1 is: H2≤[(L1-L2) / 2]*tanA1, the length of the outer surface of the main body two 32 of the split coat 3 is less than the length of the main body one 31 of the split coat 3, and the two ends of the main body one 31 There is a protruding end protruding relative to the main body 2 32. At this time, the thickness H3 of the main body 1 31 of the split casing 3 is not less than 3 mm, so as to ensure the strength of the protruding end when the axle box positioning node is loaded, and avoid deformation of the protruding end .

[0054] Specifically, the length L2 of the inner side of the main b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com