Leadless BNT-BT substrate system with large electrostrictive strain

A BNT-BT, electro-strain technology, applied in the field of lead-free BNT-BT-based systems, can solve problems such as harming human health and polluting the environment, and achieve the effect of great application prospects and excellent field-induced strain performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

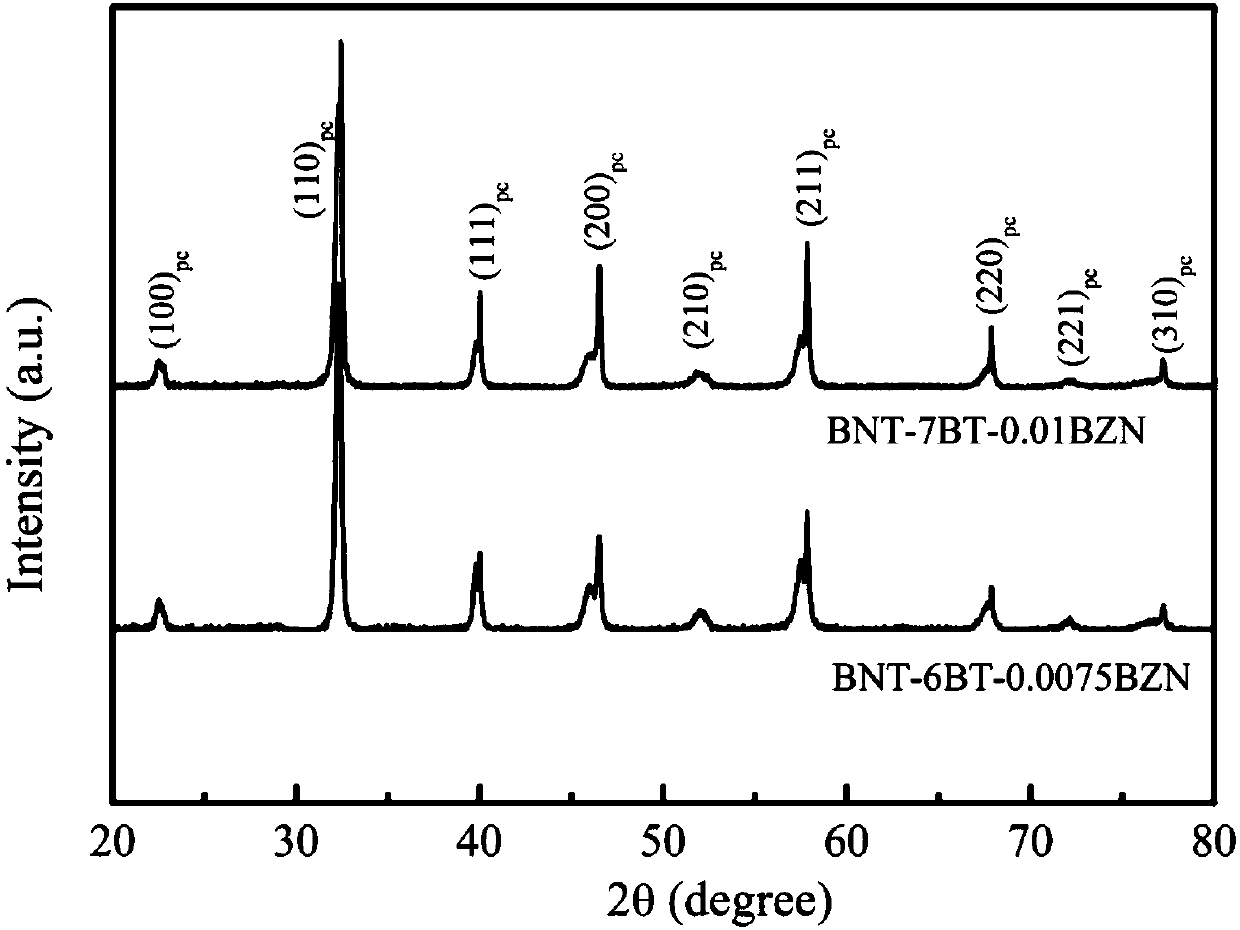

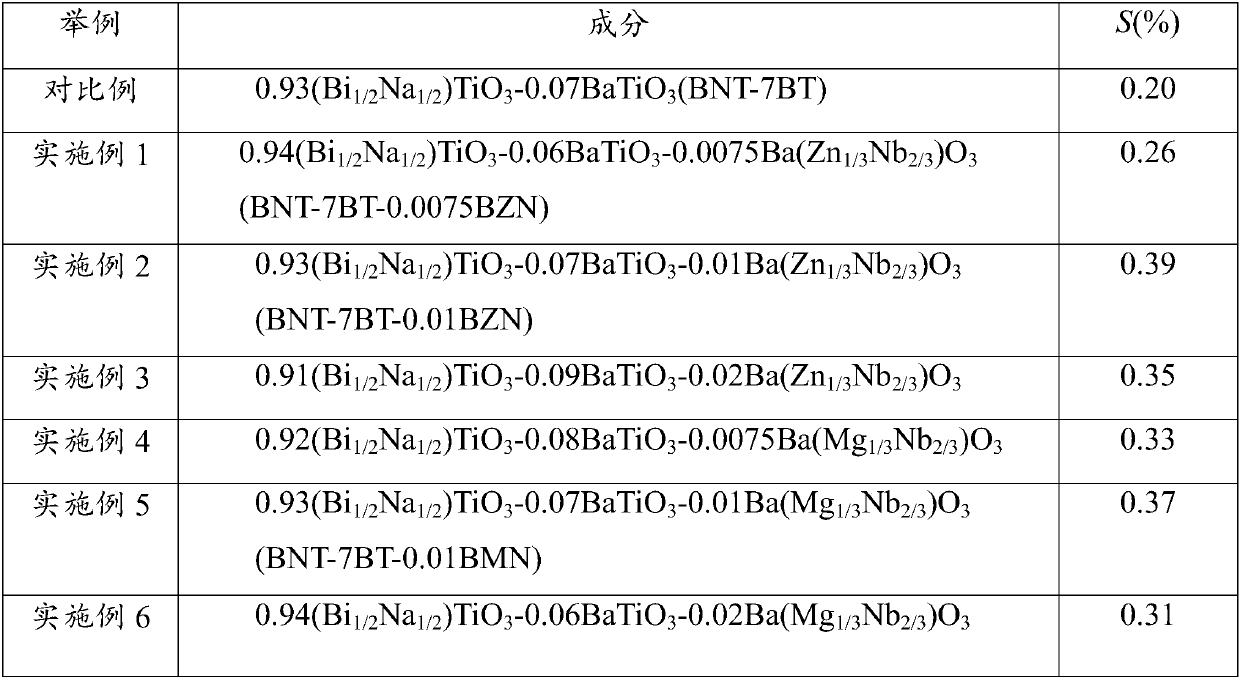

[0022] Composition: 0.94 (Bi 1 / 2 Na 1 / 2 )TiO 3 -0.06BaTiO 3 -0.0075Ba(Zn 1 / 3 Nb 2 / 3 )O 3

[0023] Process: first combine ZnO with Nb 2 o 5 combined to prepare ZnNb 2 o 6 ; Its preparation method is: according to the general chemical formula ZnNb 2 o 6 Weigh the raw materials according to the stoichiometric molar ratio, ball mill the raw materials in ethanol to make the raw materials fully mixed and uniform, dry the uniform raw materials and put them into alumina crucibles, and calcinate at 800°C for 4 hours. Second, using chemically pure Na 2 CO 3 , Bi 2 o 3 ,TiO 2 , BaCO 3 and prepared ZnNb 2 o 6 etc. as raw materials, according to the general formula (1-x) (Bi 1 / 2 Na 1 / 2 )TiO 3 -xBaTiO 3 -yBa(B 1 / 3 Nb 2 / 3 )O 3 The stoichiometric ratio of (B=Zn) weighs the raw materials; ball mill the raw materials in ethanol to fully mix the raw materials, dry the uniformly mixed raw materials and put them into an alumina crucible, and calcinate them at 900°C for a ...

Embodiment 2

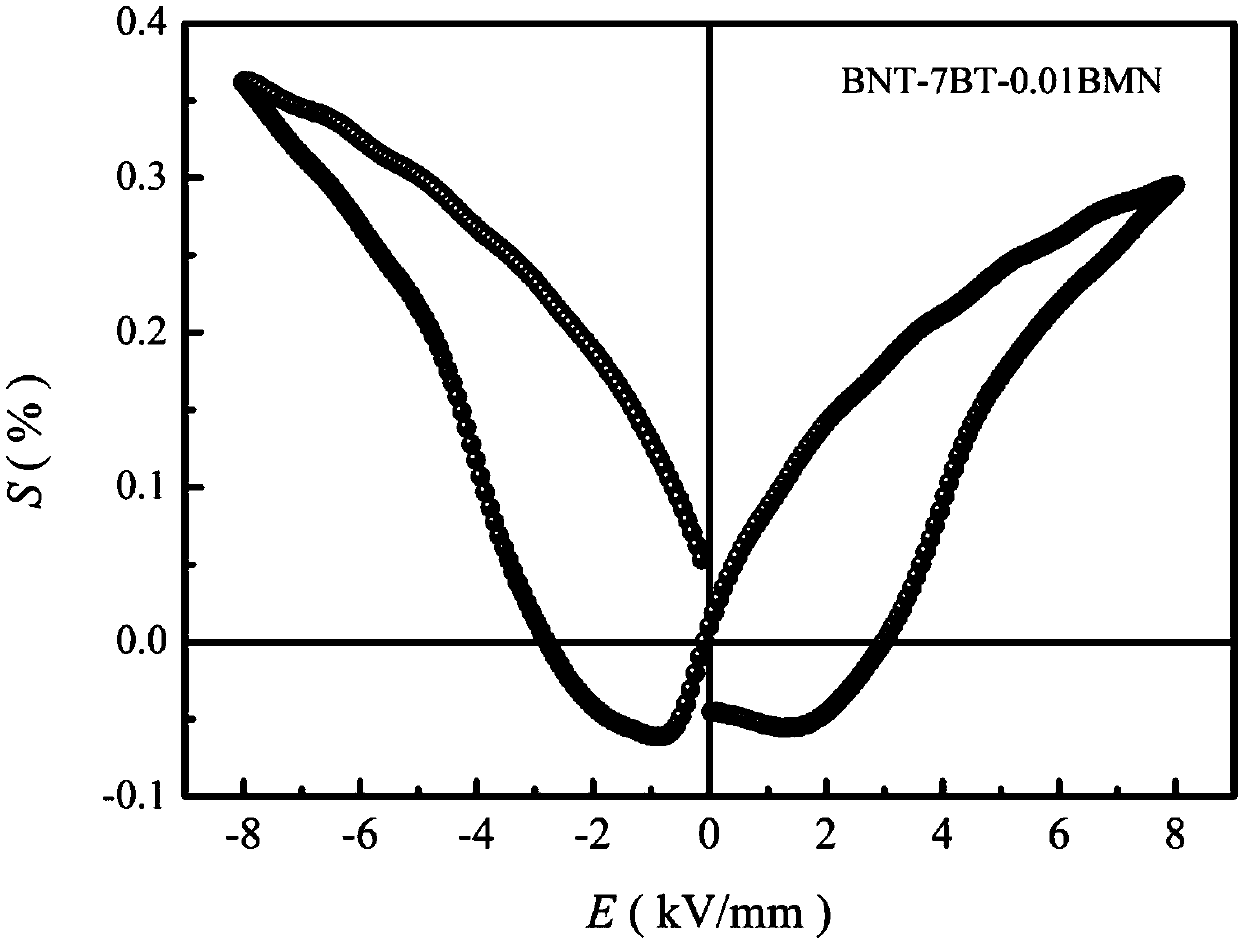

[0025] Composition: 0.93(Bi 1 / 2 Na 1 / 2 )TiO 3 -0.07BaTiO 3 -0.01Ba(Zn 1 / 3 Nb 2 / 3 )O 3

[0026] Process: ZnNb 2 o 6 The calcination temperature is 850° C., and the holding time is 2 hours; the calcination temperature of the general ceramic is 850° C., the sintering temperature is 1150° C., the holding temperature is 4 hours, and the pressure is 300 MPa. Others are the same as in Example 1.

Embodiment 3

[0028] Composition: 0.91(Bi 1 / 2 Na 1 / 2 )TiO 3 -0.09BaTiO 3 -0.02Ba(Zn 1 / 3 Nb 2 / 3 )O 3

[0029] Process: ZnNb 2 o 6 The calcination temperature is 800° C., and the holding time is 3 hours; the calcination temperature of the general ceramic is 800° C., the sintering temperature is 1000° C., the holding temperature is 2 hours, and the pressure is 300 MPa. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com