Polyimide precursor, polyimide and manufacturing method of transparent polyimide film

A technology of polyimide precursor and polyimide film, applied in the direction of coating, etc., to achieve the effects of simple dimensional stability, excellent heat resistance, and excellent laser peeling characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

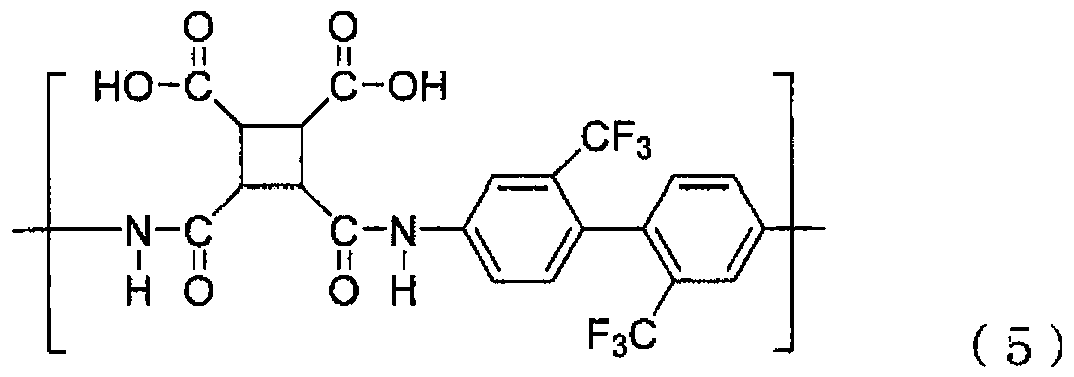

[0122] Under nitrogen flow, 9.17 g of TFMB were dissolved in 85 g of NMP in a 100 ml separable flask. Next, 5.00 g of CBDA was added to the solution. After stirring for 10 minutes 0.83 g of BPDA was added. In addition, the molar ratio of a diamine component and a tetracarboxylic dianhydride component was made into 0.99 (substantially equimolar). Thereafter, the solution was continuously stirred at room temperature for 24 hours to conduct a polymerization reaction to obtain polyamic acid A (a viscous colorless solution) with a high degree of polymerization (Mw 80,000 or more, viscosity 3,000 cP or more).

Embodiment 2~ Embodiment 9、 comparative example 1~ comparative example 7

[0124] Except having changed the diamine and tetracarboxylic dianhydride which are raw materials into the composition shown in Table 1 and Table 2, the polyamic-acid solution was prepared similarly to Example 1, and polyamic-acid B - polyamic-acid P were obtained.

[0125] In addition, in Table 1 and Table 2, the unit of the quantity of diamine and tetracarboxylic dianhydride is g, and the numerical value in parentheses shows the mol% in a diamine component or a tetracarboxylic dianhydride component.

[0126] [Table 1]

[0127]

[0128] [Table 2]

[0129]

Embodiment 10

[0131] Add the solvent NMP to the polyimide precursor solution A obtained in Example 1, dilute it so that the viscosity becomes 4000cP, and then use a spin coater so that the thickness of the cured polyimide becomes about 15 μm It was applied on a glass substrate (E-XG manufactured by Corning, size=150 mm×150 mm, thickness=0.7 mm). Next, heating was performed at 100° C. for 15 minutes. Then, in a nitrogen atmosphere, the temperature was raised from room temperature to 300°C (360°C in Comparative Example 10) at a certain rate of temperature rise (3°C / min), and kept at 130°C for 10 minutes in the middle, thereby forming a 150mm× 150 mm of polyimide layer (polyimide A), and polyimide laminated body A was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com