A method and material for obtaining a magnetostrictive material with low driving field and large magnetic strain

A technology of magnetostrictive materials and magnetostrictive strain, which is applied in the material selection of magnetostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, and the selection of device materials, etc., which can solve the problem of inability to obtain magnetostrictive Material and other issues, to achieve the effect of clear and easy method, small saturation magnetic field and high production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment discloses a method for obtaining a magnetostrictive material with low driving field and large magnetostrictive strain, which includes: reducing the existing micron-scale martensite domains in the material to nano-scale to obtain nano-martensite domains . Further, the above-mentioned nano-martensite domains are obtained by doping normal ferromagnetic martensite materials.

[0044] For this embodiment, it embodies the principles of the present disclosure. The inventors found in their research that the martensitic phase transition that occurs in traditional ferromagnetic shape memory alloys is often a thermodynamic first-order phase transition. After the phase transition occurs, long-range ordered martensitic domains are formed, and the microstructure is expressed as micron twins formed by martensite domains. Although the reorientation effect of the micron-scale martensitic "big" domain driven by a magnetic field will produce a huge amount of magnetostric...

Embodiment 2

[0049] This embodiment discloses the performance and preparation method of a polycrystalline sample of magnetostrictive material with low driving field and large magnetic strain:

[0050] 1. Properties of polycrystalline samples

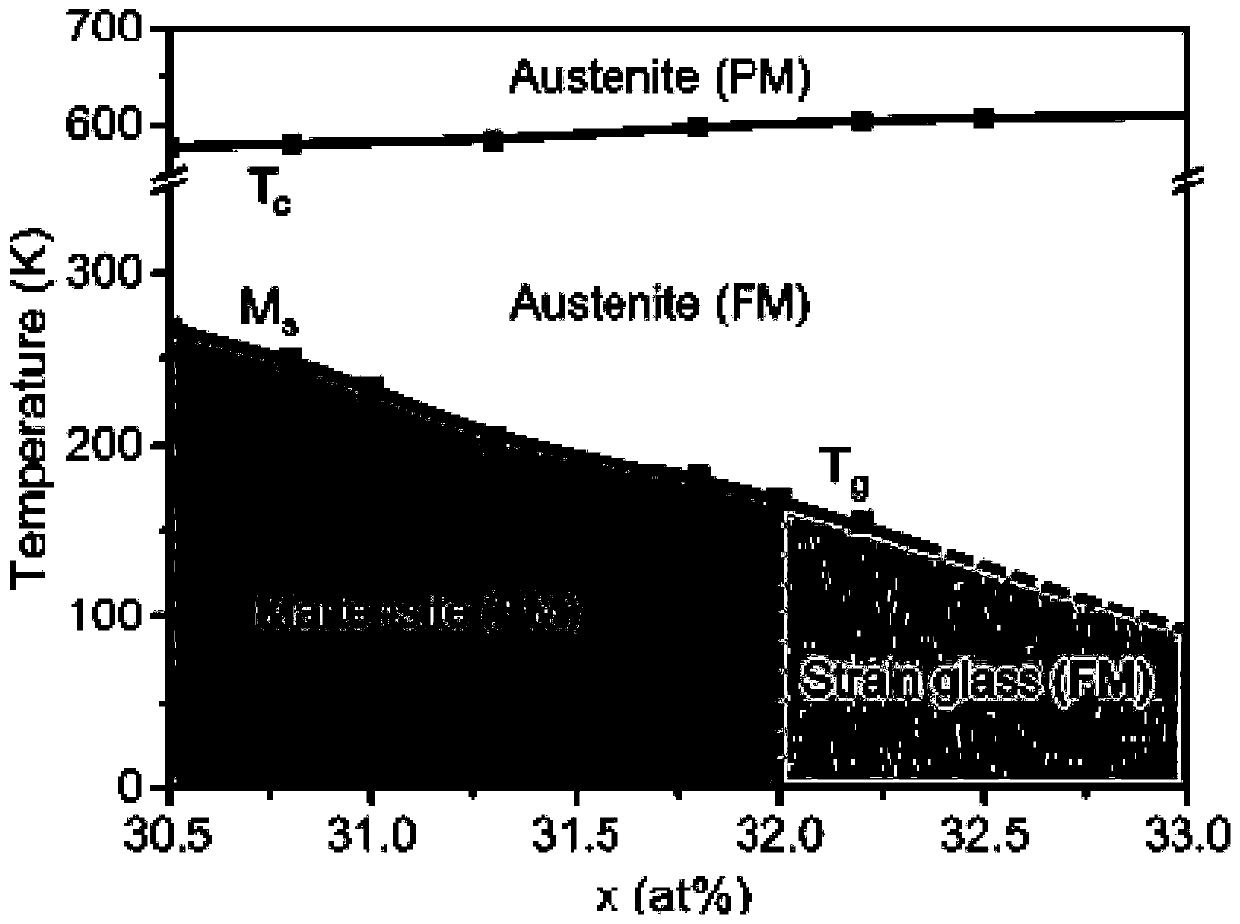

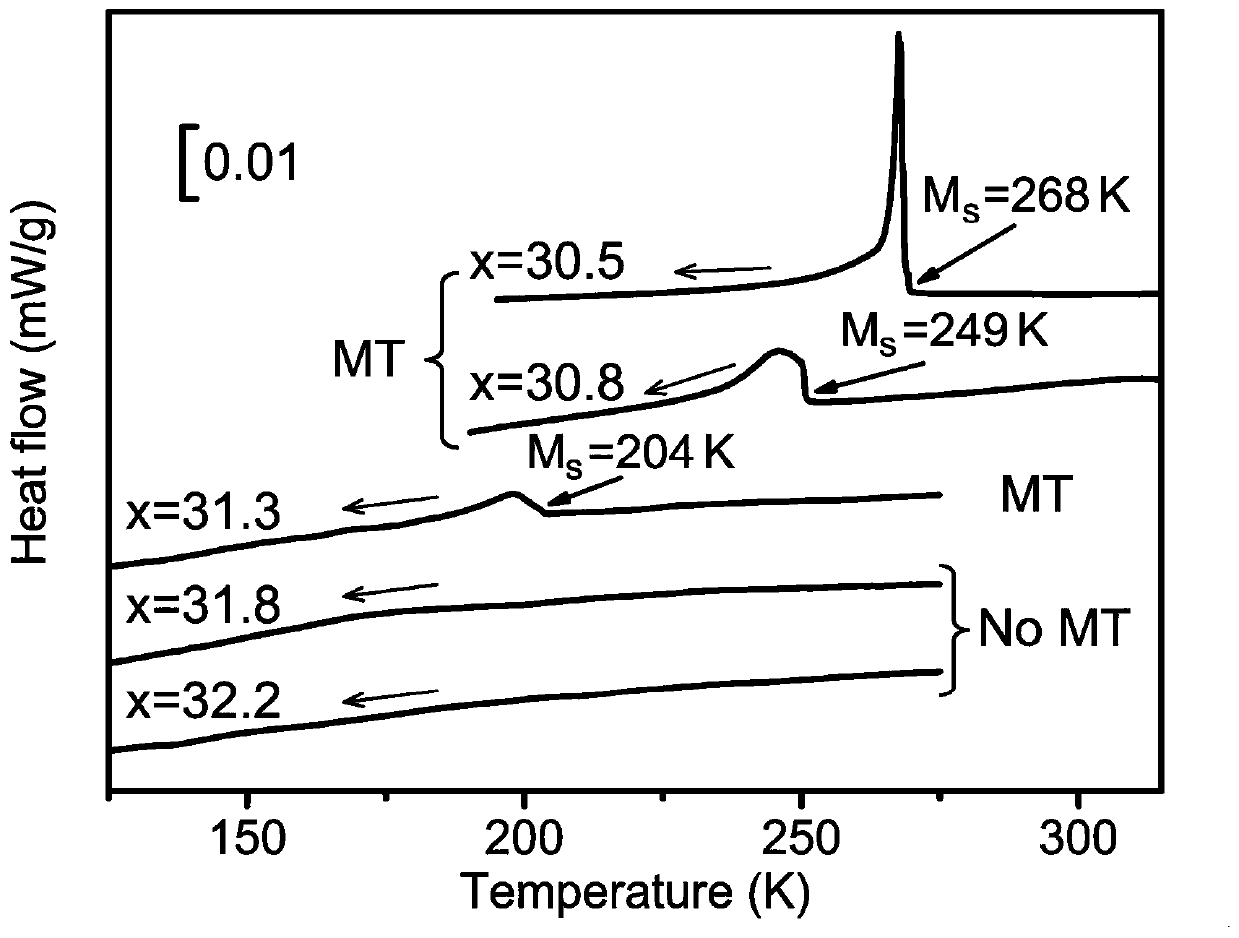

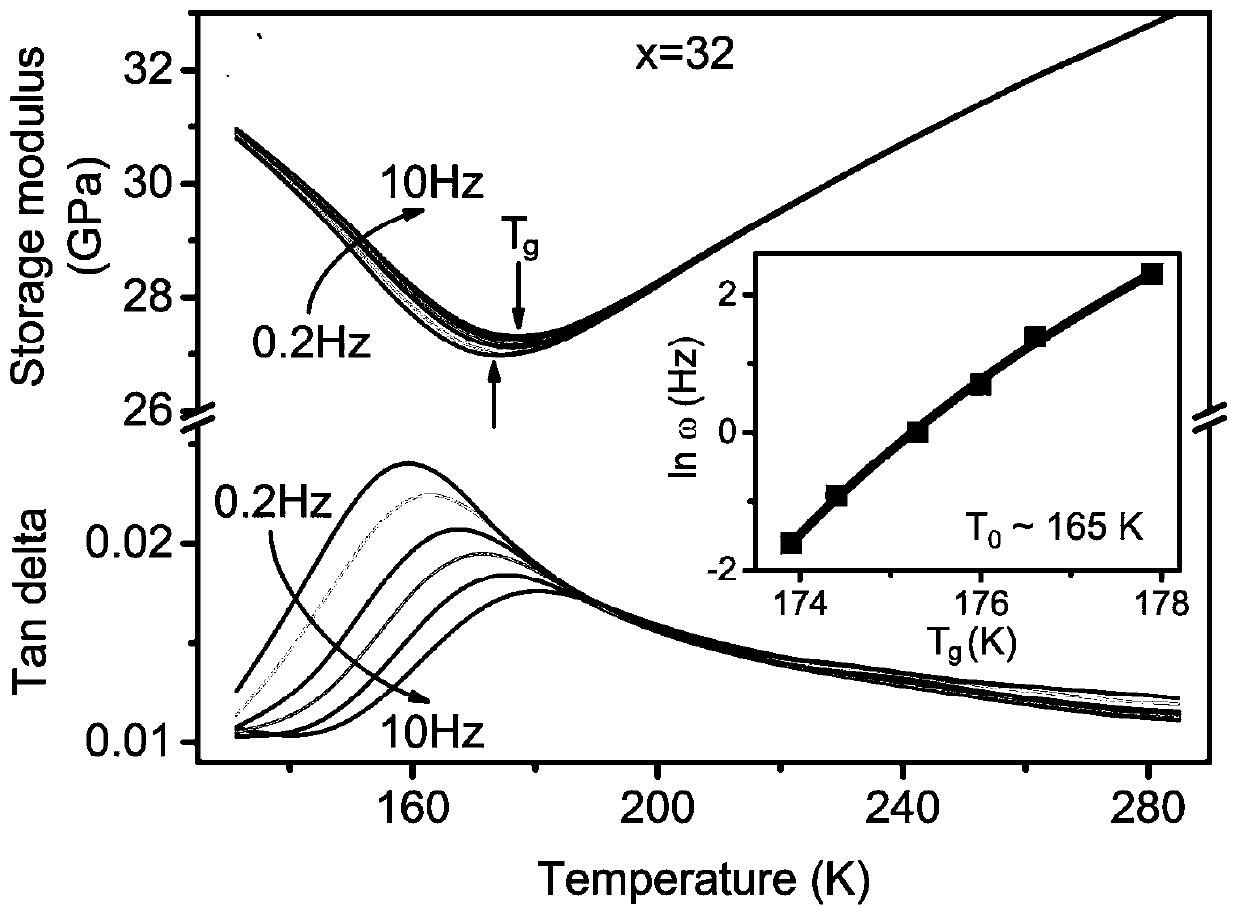

[0051] This embodiment specifically discloses a polycrystalline sample of a magnetostrictive material with a low driving field and a large magnetic strain, the general chemical formula of which is Fe 100-x PD x . Wherein, the values of x are successively: x=30.5, x=30.8, x=31.3, x=31.8, x=32, x=32.2, x=33. Near the phase transition point of the magnetostrictive material, its magnetostriction coefficient is not less than 90ppm, and the required saturation magnetic field is not greater than 1kOe. In particular, as Figures 3a-3d As shown, when x=30.5, near its phase transition point (~268K), its magnetostriction coefficient can reach 90ppm, and the required saturation magnetic field is not more than 1kOe; when x=32, near the glass transition poin...

Embodiment 3

[0060] This embodiment discloses the performance and preparation method of a directionally solidified sample of a magnetostrictive material with low driving field and large magnetic strain:

[0061] 1. Properties of directionally solidified samples

[0062] This embodiment specifically discloses a directionally solidified sample of a magnetostrictive material with low driving field and large magnetic strain, whose general chemical formula is Fe 100-x PD x . Wherein, the values of x are sequentially: x=30, x=31.3, x=31.8, x=32, x=32.3. Near the phase transition point of the magnetostrictive material, its magnetostriction coefficient is not less than 280ppm, and the required saturation magnetic field is not greater than 1kOe. In particular, as Figures 4a-4e As shown, when x=31.3, its maximum magnetostriction can reach 340ppm at slightly lower than its phase transition point (~212K), and the reversible magnetostriction of subsequent cycles can reach 280ppm, and the require...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com