Continuous open-width bleaching and washing equipment for high-efficiency and energy-saving knitted fabrics

A high-efficiency, energy-saving, water-washing equipment technology, applied in the field of fabric bleaching, can solve the problems of poor fabric bleaching quality, poor fabric quality, low efficiency, etc., and achieve the effects of improving bleaching quality and quality, improving production efficiency, and improving bleaching quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

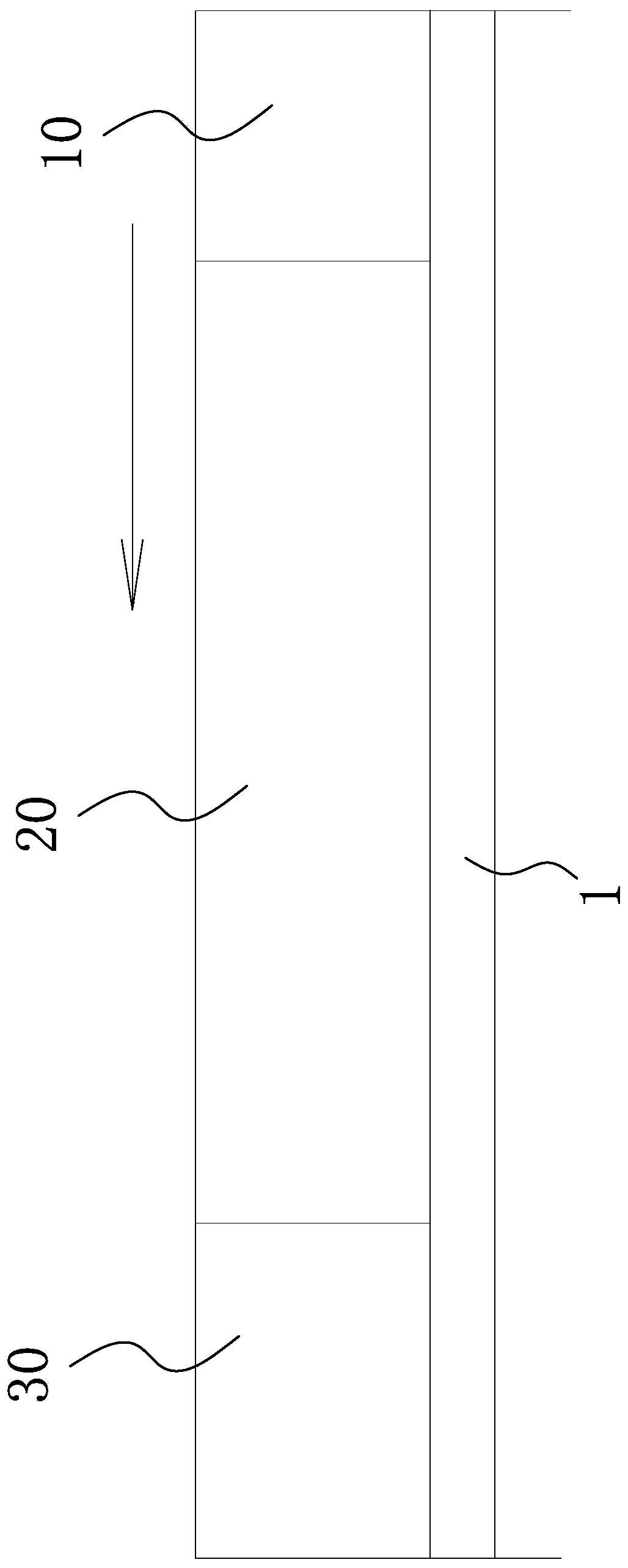

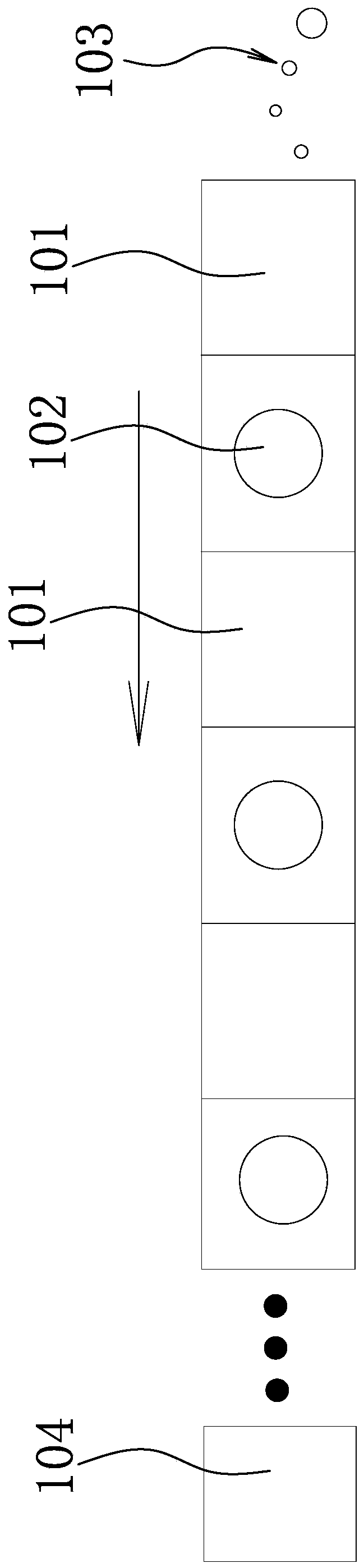

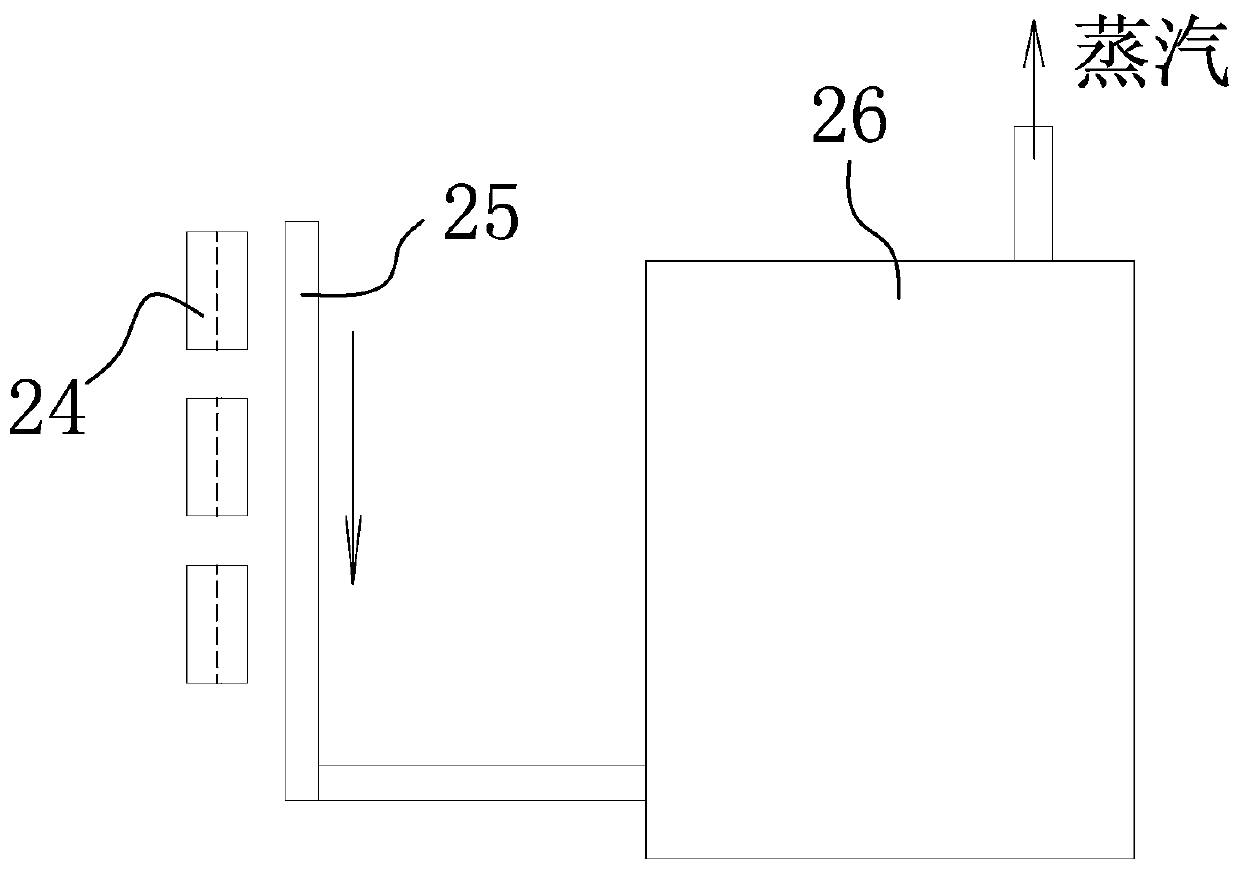

[0046] Such as Figure 1-2 As shown, the high-efficiency and energy-saving continuous open-width bleaching and washing equipment for knitted fabrics includes a frame 1, and an open-width pretreatment system 10, a steam bleaching system 20, and a flat-width post-treatment system 30 are arranged in sequence on the frame 1, specifically Specifically, the open-width pretreatment system 10 includes at least two primary washing devices 101 and primary filtering devices 102 equal in number to the primary washing devices 101. The primary washing devices 101 are arranged at intervals, and the primary filtering devices 102 are arranged at intervals. Each primary washing device The rear of 101 is provided with a primary filtering device 102 respectively.

[0047] The above-mentioned one-time water washing device is the 250 type in the frame.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com