Prefabricated floating slab ballast bed vibration isolation system

A vibration isolation system and floating plate technology, applied in the directions of roads, tracks, ballast layers, etc., can solve problems such as slow construction speed, achieve good vibration isolation ability, easy maintenance and maintenance, and ensure the effect of driving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

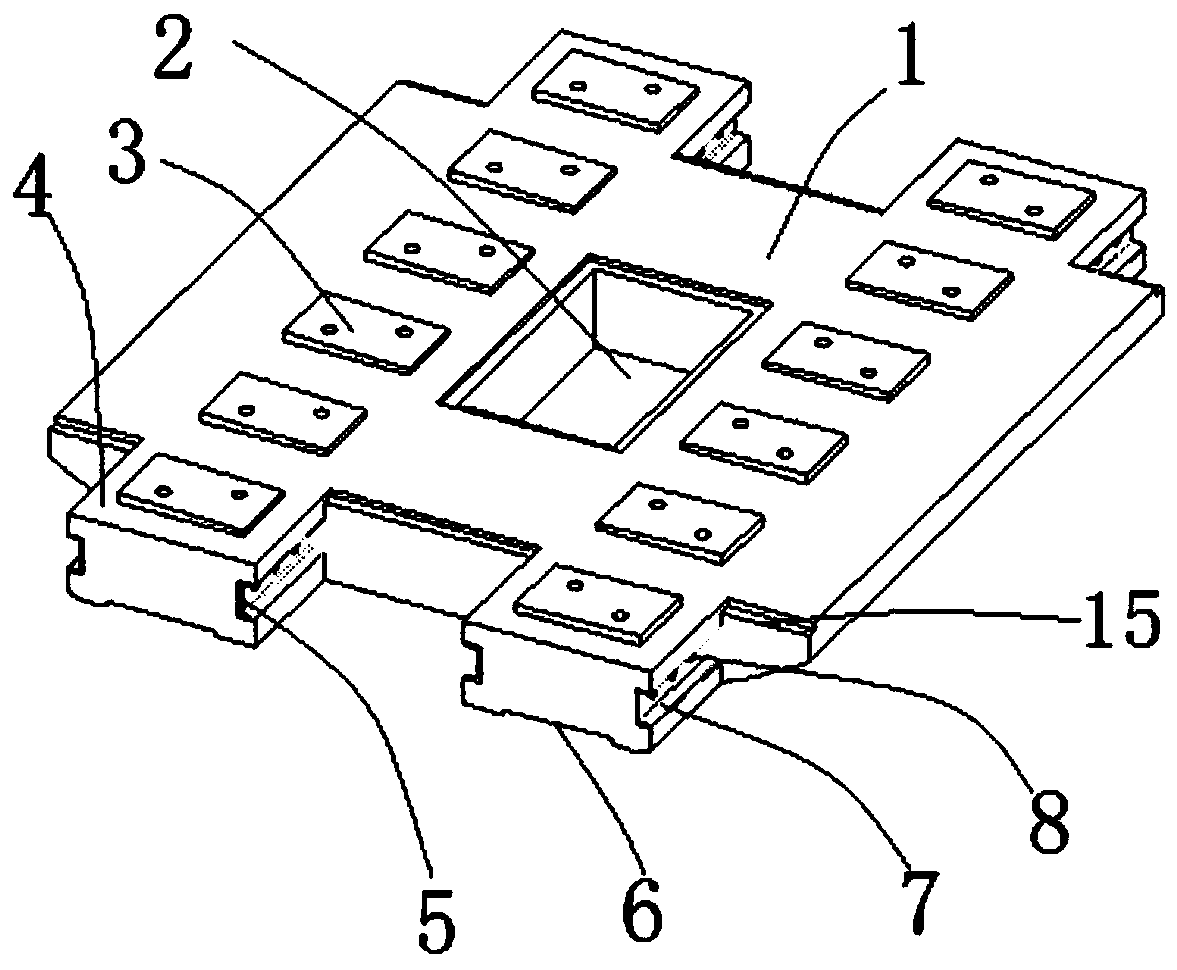

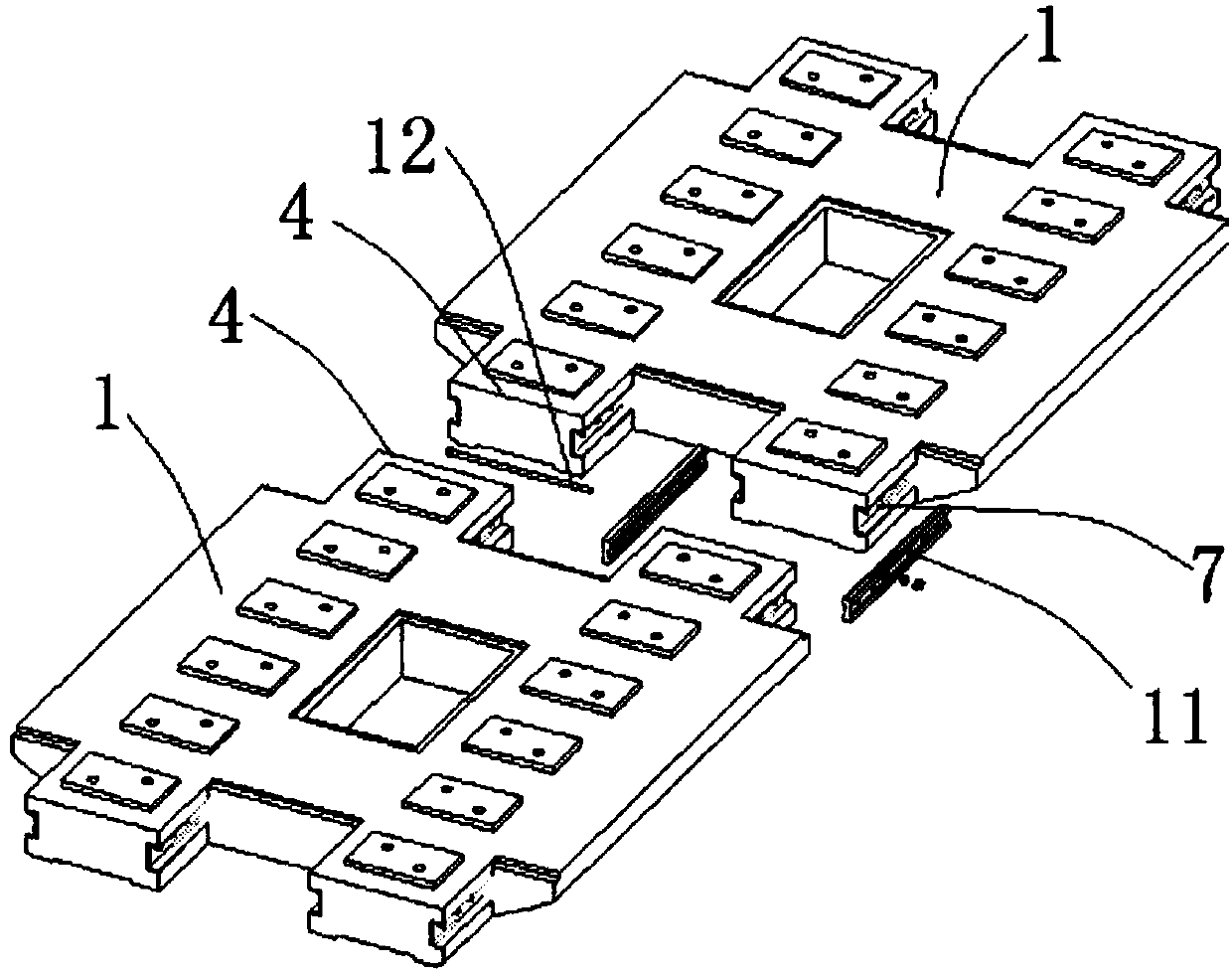

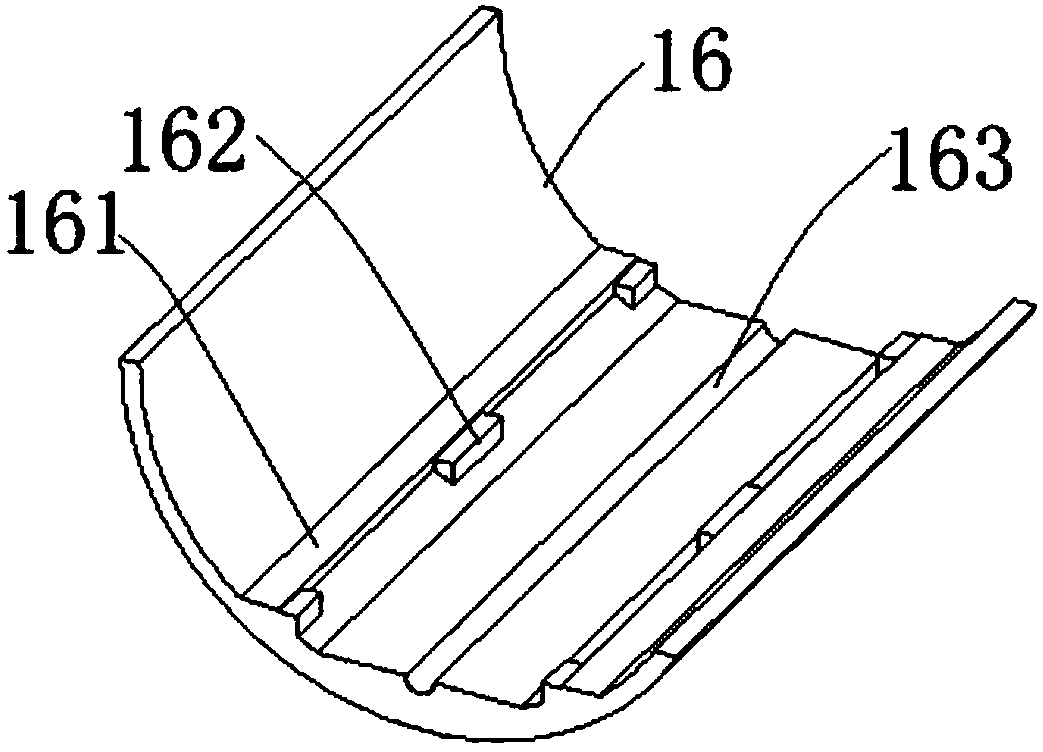

[0021] A prefabricated floating slab track bed vibration isolation system, please refer to Figure 1 to Figure 5 In order to facilitate transportation, several groups of floating slabs are spliced adjacent to each other to form a long track bed, the long track bed is embedded in the bottom of the tunnel structure 16, and the outer contour of the long track bed is inlaid with the bottom of the tunnel structure 16 Connection, in order to facilitate on-site splicing and installation, the floating slab is set as a precast concrete slab 1 with a well-shaped structure. Short sleepers 3 are arranged at equal intervals in the long direction. In order to further facilitate on-site splicing and installation, connecting arms 4 are extended on both sides of the waist of the precast concrete slab 1, and U-shaped grooves 5 with openings facing outwards a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com