Hand-push type rolling brush scribing machine

A scribing machine and hand-push type technology, applied in the field of hand-push roller brush scribing machines, can solve the problems of inconvenient use in small construction sites, complex structure and layout, and many power losses, and achieve compact structure and installation of roller brush wheels. Convenient and easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

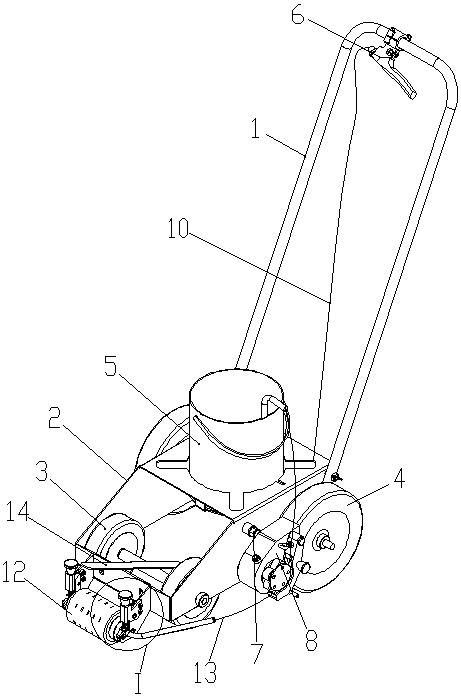

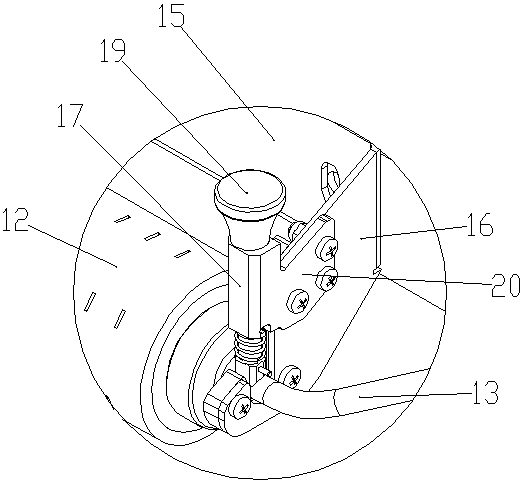

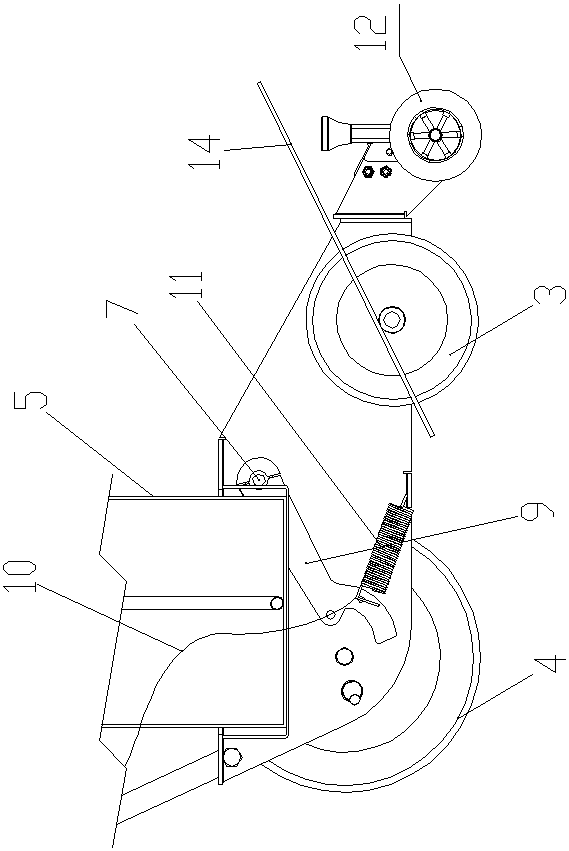

[0026] Such as Figure 1-7 As shown, the hand-push rolling brush marking machine of the present invention includes a push handle 1 and a vehicle frame 2, and two front wheels 3 are provided on the bottom front side of the vehicle frame 2, and two front wheels 3 are provided on the bottom rear side of the vehicle frame 2. Rear wheel 4, push handle 1 is fixed on the rear side of vehicle frame 2, and paint bucket 5 is fixed on the vehicle frame 2, is provided with hand brake 6 on the push handle 1, and the left side on the vehicle frame 2 is worn with bearing pin 7, and pin The shaft 7 is arranged along the left and right horizontal directions, and the pin shaft 7 is fixed with a peristaltic pump 8 and a pull plate 9, one end of the pull plate 9 is a hinged end, the other end of the pull plate 9 is a movable end, and the hinged end of the pull plate 9 is connected to the pin shaft. 7 is fixedly connected, the movable end of the pull plate 9 is connected with the hand brake 6 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com