Adhesive-free testing device and method for rock direct tensile test

A technology of tensile test and test device, which is applied in the direction of measuring device, using stable tension/pressure test material strength, instruments, etc., can solve problems such as uneven adhesive thickness, insufficient bonding strength, and test failure. Achieve the effect of avoiding bonding fracture, easy operation and low requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

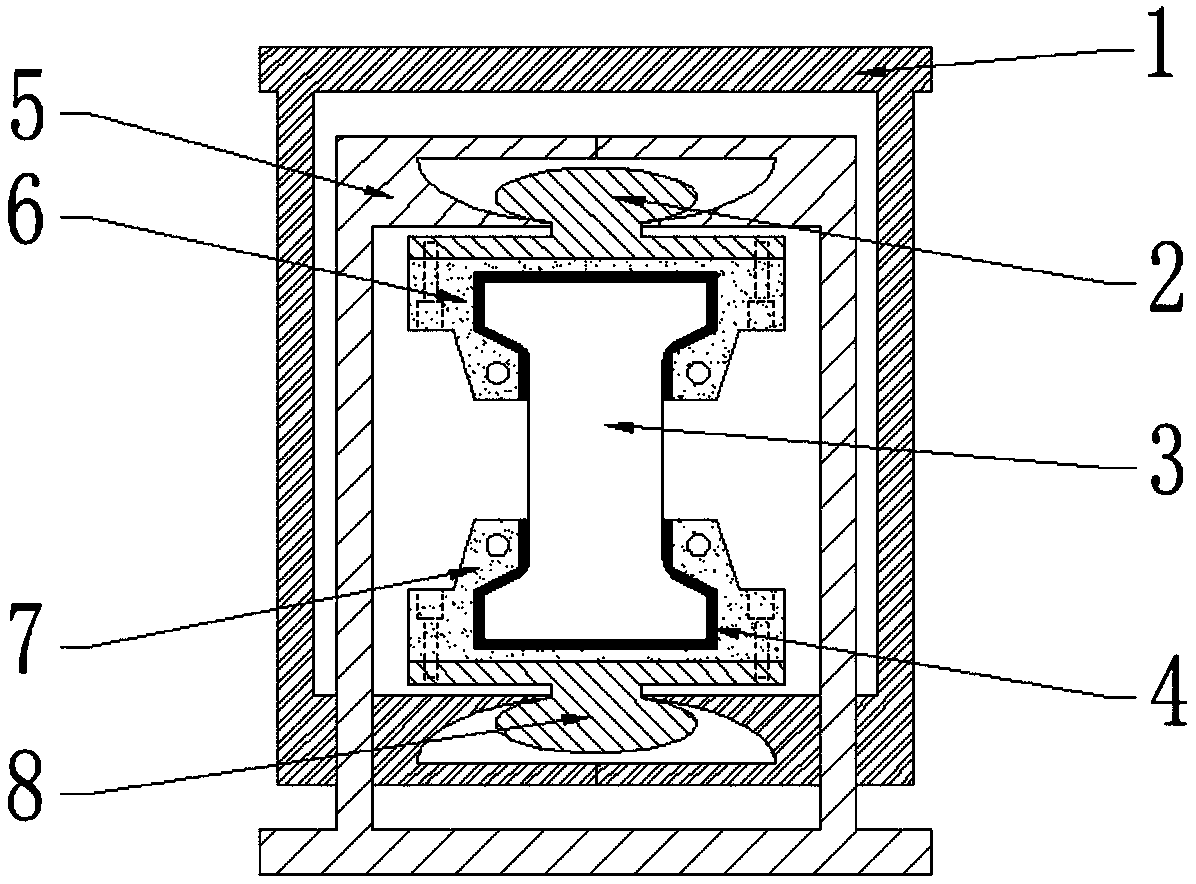

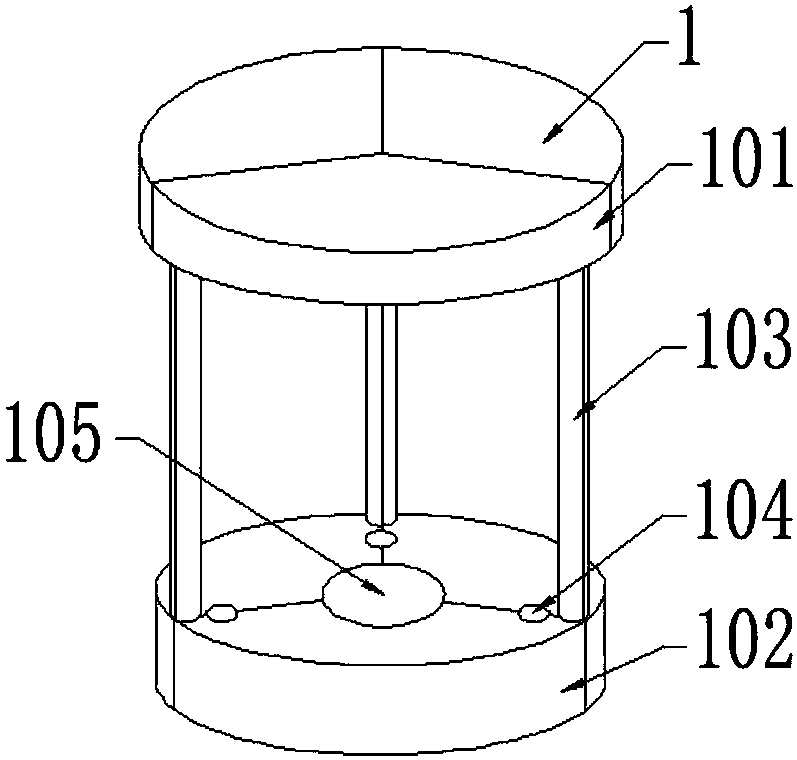

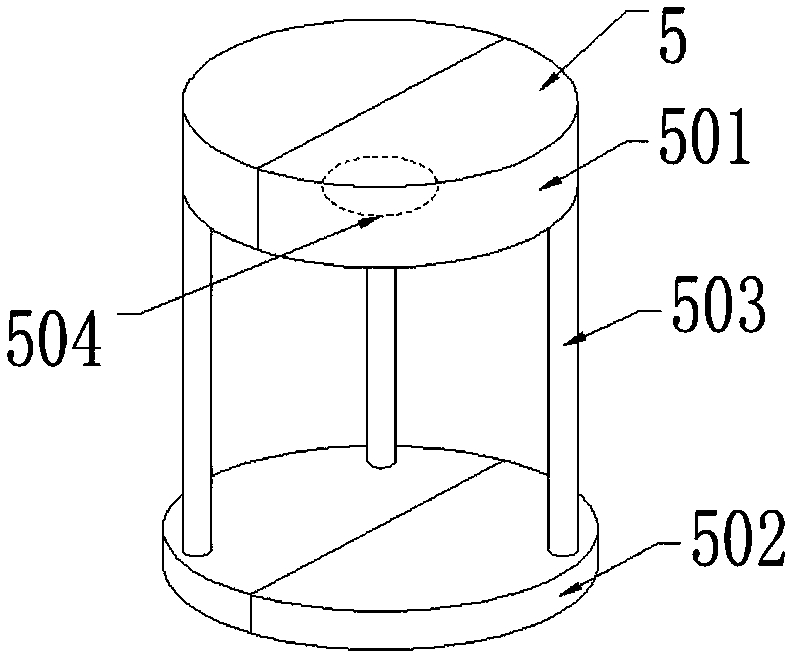

[0031] This embodiment provides a stick-free test device for direct tensile test of rock, such as figure 1 shown, including the outer bracket 1 and the inner bracket 5, such as figure 2 As shown, the outer bracket 1 and the inner bracket 5 are sleeved together with the inner bracket column 503 through the inner bracket column mounting holes 104. The outer bracket 1 includes an outer bracket upper plate 101 and an outer bracket lower plate 102 arranged in parallel, and the outer bracket upper plate 102. Between 101 and the lower plate 102 of the outer bracket, the upper and lower plates of the outer bracket are installed with outer bracket pillars 103, the lower plate 102 of the outer bracket is provided with the mounting hole 104 of the inner bracket pillar, and the center position of the upper surface of the lower plate 102 of the outer bracket is There is a pull-down head mounting hole 105; such as image 3 As shown, the inner bracket 5 includes an inner bracket upper plat...

Embodiment 2

[0034] The present embodiment provides a non-stick test method for direct tensile test of rock, including the following specific steps:

[0035] (1) An incompletely closed ellipsoid pull-down head installation hole 105 is reserved at the center of the lower plate 102 of the outer bracket, and the fixing part of the pull-down head 8 is installed in it, and the upper pull-down head 2 is installed in the inner bracket in the same way Inside the incompletely closed ellipsoid upper slider mounting hole 504 at the inner center position of the upper plate 501; then the outer bracket upper plate 101 and the outer bracket lower plate 102 are welded and combined into a whole by the outer bracket struts 103; the inner bracket struts 503 passes through the mounting holes 104 of the inner support struts on the outer support lower plate 102, and then the inner support upper plate 501 and the inner support lower plate 502 are welded and assembled into the inner support 5 through the inner sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com