An integrated test platform and method for test piece stamping forming and mechanical parameter testing

A technology of mechanical parameters and stamping forming, which is applied in the field of integrated test platform for stamping forming and mechanical parameter testing of specimens, can solve the problem of reducing the stability of mechanical properties of specimens of similar materials, errors in model test results, and inconsistencies in the degree of compaction of specimens and other issues, to achieve the effect of high cost performance, reduce impact, improve stability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

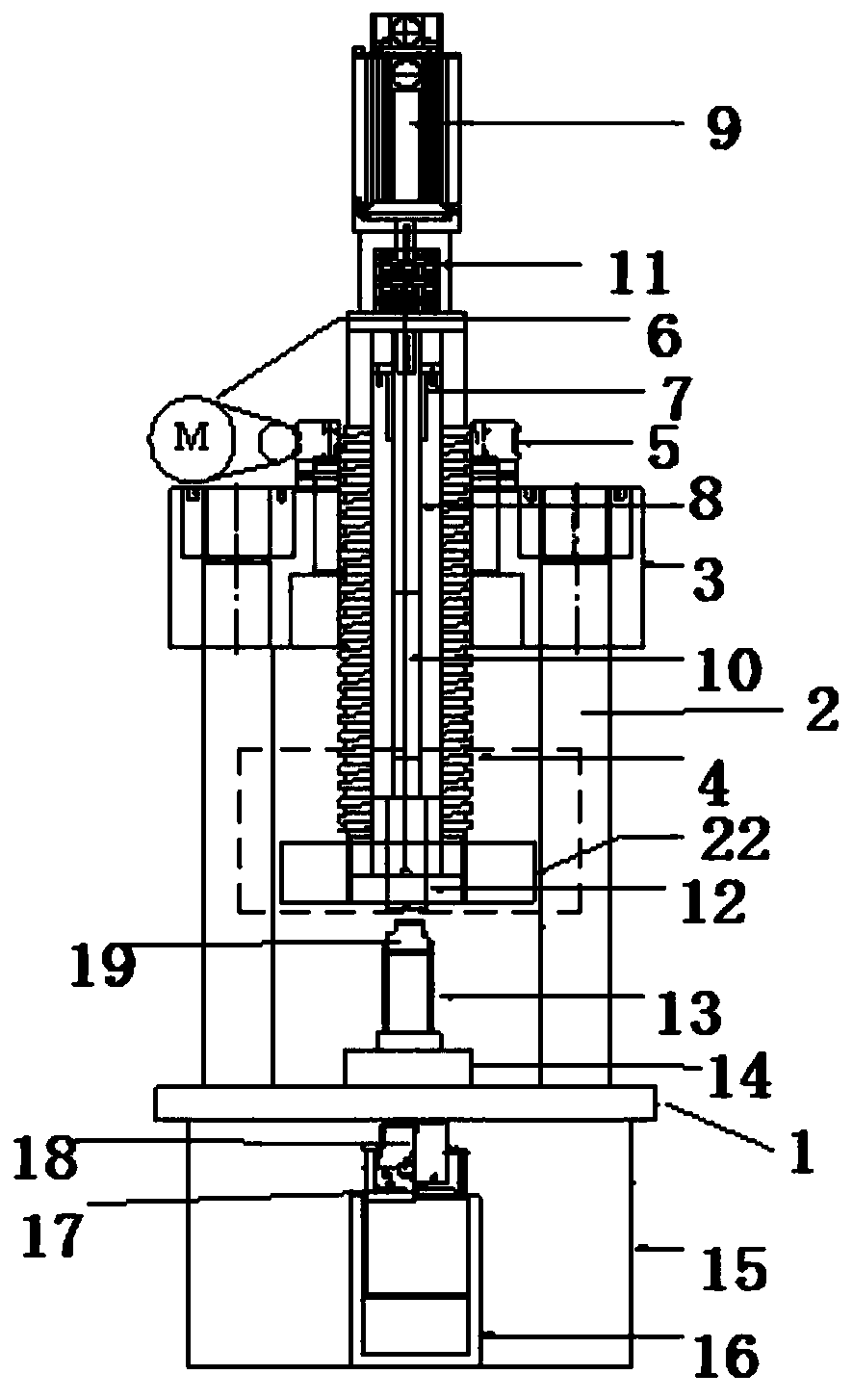

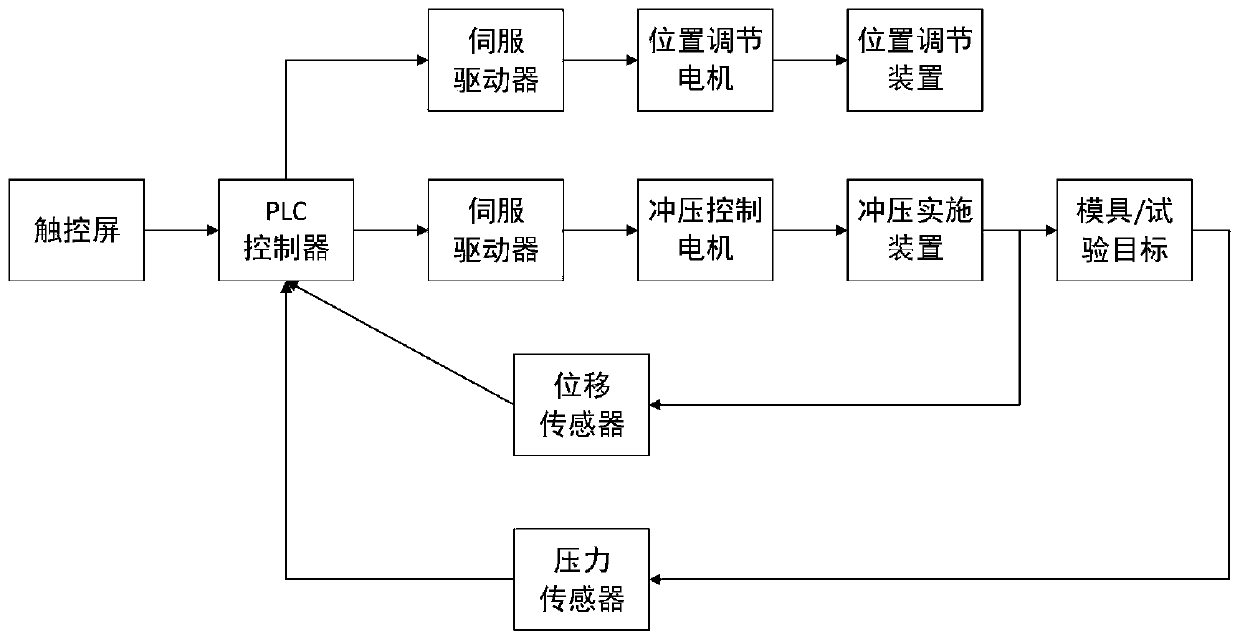

[0042] The invention provides an integrated test platform for test piece stamping forming and mechanical parameter testing, such as figure 1 As shown, the main structure includes a lower pressure-bearing base plate 1, on which four symmetrically arranged guide posts 2 are fixed, the top of the guide posts 2 is threadedly mounted with an upper beam 3 with an opening in the middle, and the opening of the upper beam 3 There is a main pressure-bearing screw 4 pierced there. The outer wall of the main pressure-bearing screw 4 is a helical structure, and the main pressure-bearing screw lifting turbine 5 is connected by threads. The main pressure-bearing screw lifting turbine 5 passes through the drive motor 6 on the upper beam 3. control.

[0043] The main bearing screw 4 is hollow inside, and a ball screw nut pair 7 is fixed on the upper part of the inner wall of the main bearing screw 4. The ball screw nut pair 7 is connected with a ball screw 8 through a thread, and the upper par...

Embodiment 2

[0046] This embodiment is a further improvement on the basis of the first embodiment, and has all the structures of the first embodiment. On the basis of the first embodiment, the present invention has made some structural deformations and supplements. 1 is provided with four symmetrical guide columns 2 , an upper beam 3 is respectively connected between every two adjacent guide columns 2 through threads, and the main pressure bearing screw 4 is arranged in the space between the two upper beams 3 .

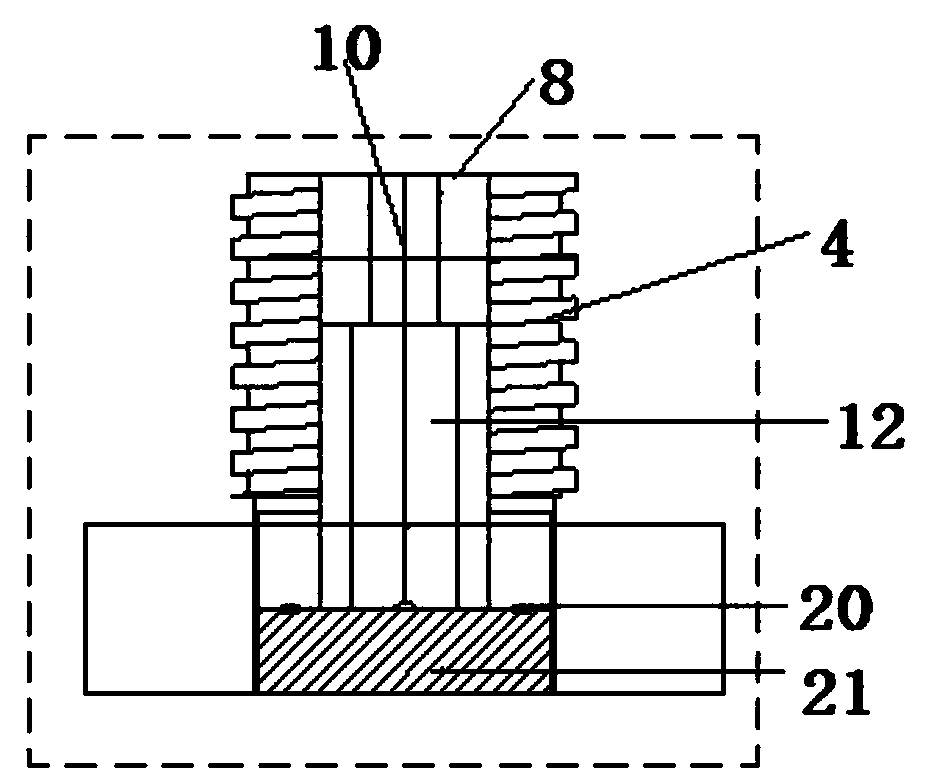

[0047] The stamping die 13 in the present invention is provided with a die pressing head 19, and a protective pressing plate 21 is adsorbed by the magnetic steel 20 in the hollow of the upper pressing plate 22 connected to the lower end of the main pressing screw 4, and the bottom surface of the protective pressing plate 21 is connected to the upper The bottom surface of the pressure-bearing plate 22 is flush, and the protective pressure plate 21 closely fits with the hollow inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com