Heating furnace flame real-time detection method based on average gray scale and area

A technology of average grayscale and real-time detection, applied in image data processing, instrumentation, computing, etc., can solve the problems of false alarms, efficiency drop, and influence detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

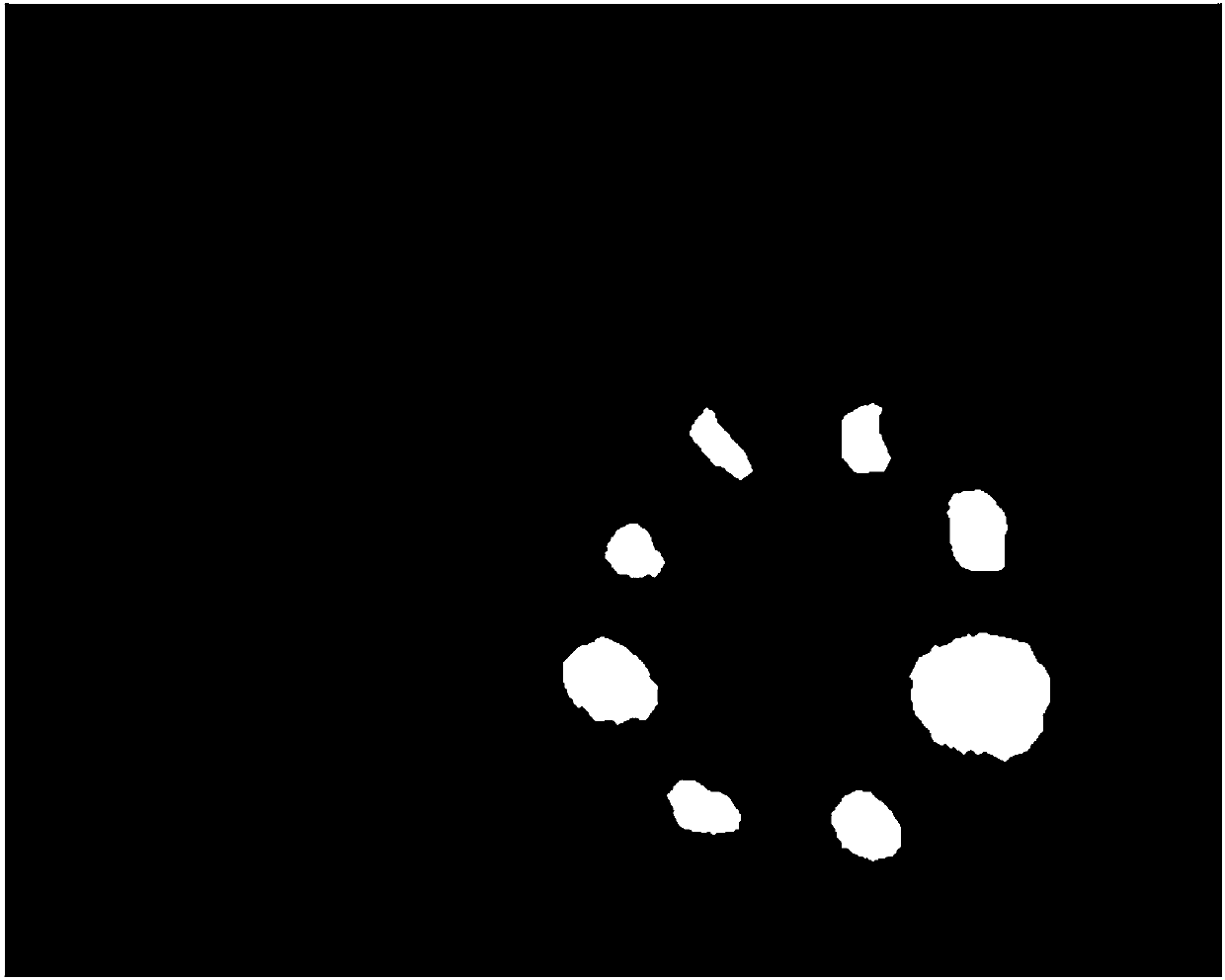

[0114] In this embodiment, a real-time flame detection for heating furnace based on average gray scale and area. The hardware platform is a personal microcomputer, the operating system is Windows, the image development platform is Intel OpenCV, and the development tool is Microsoft Visual C++. The specific steps are:

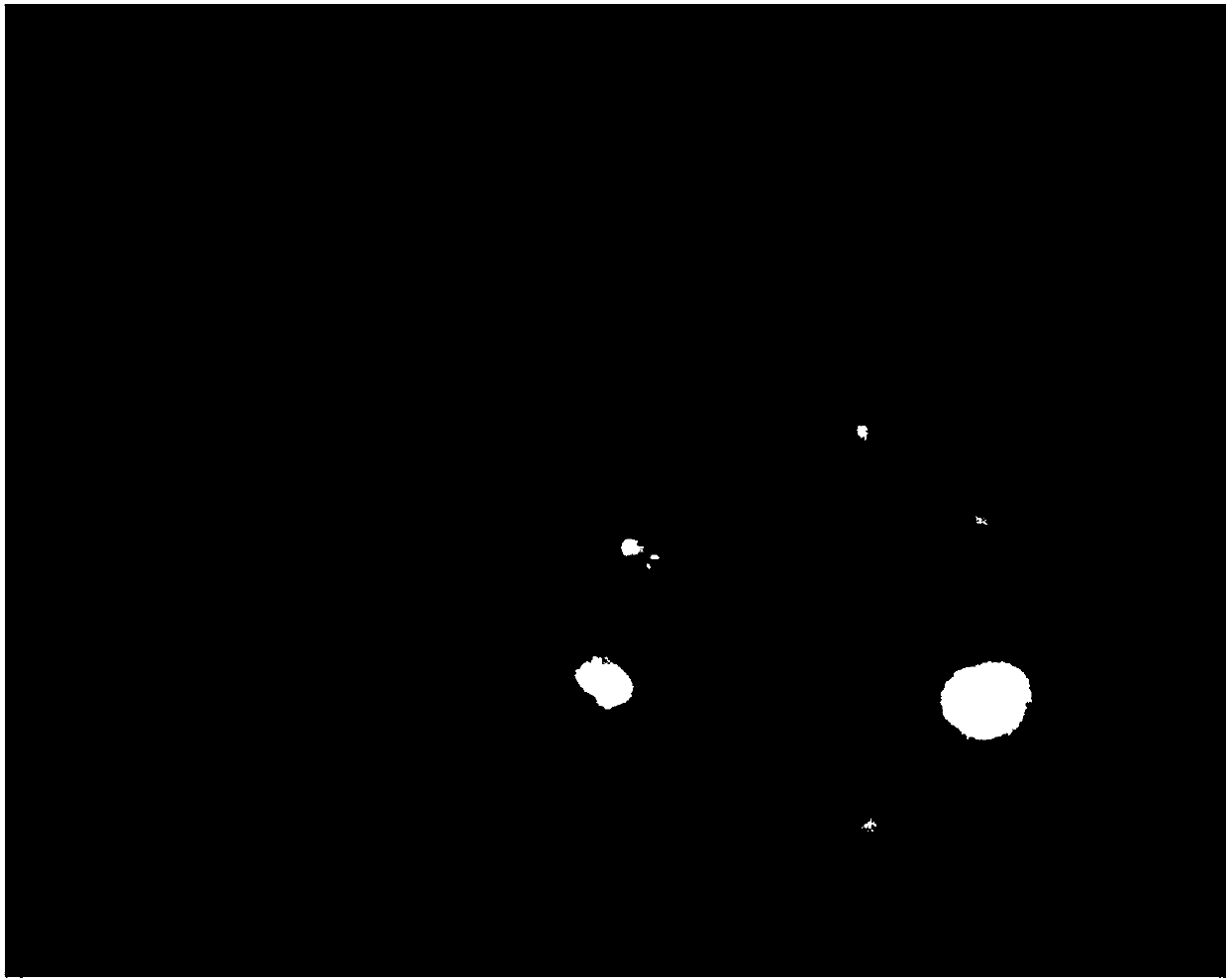

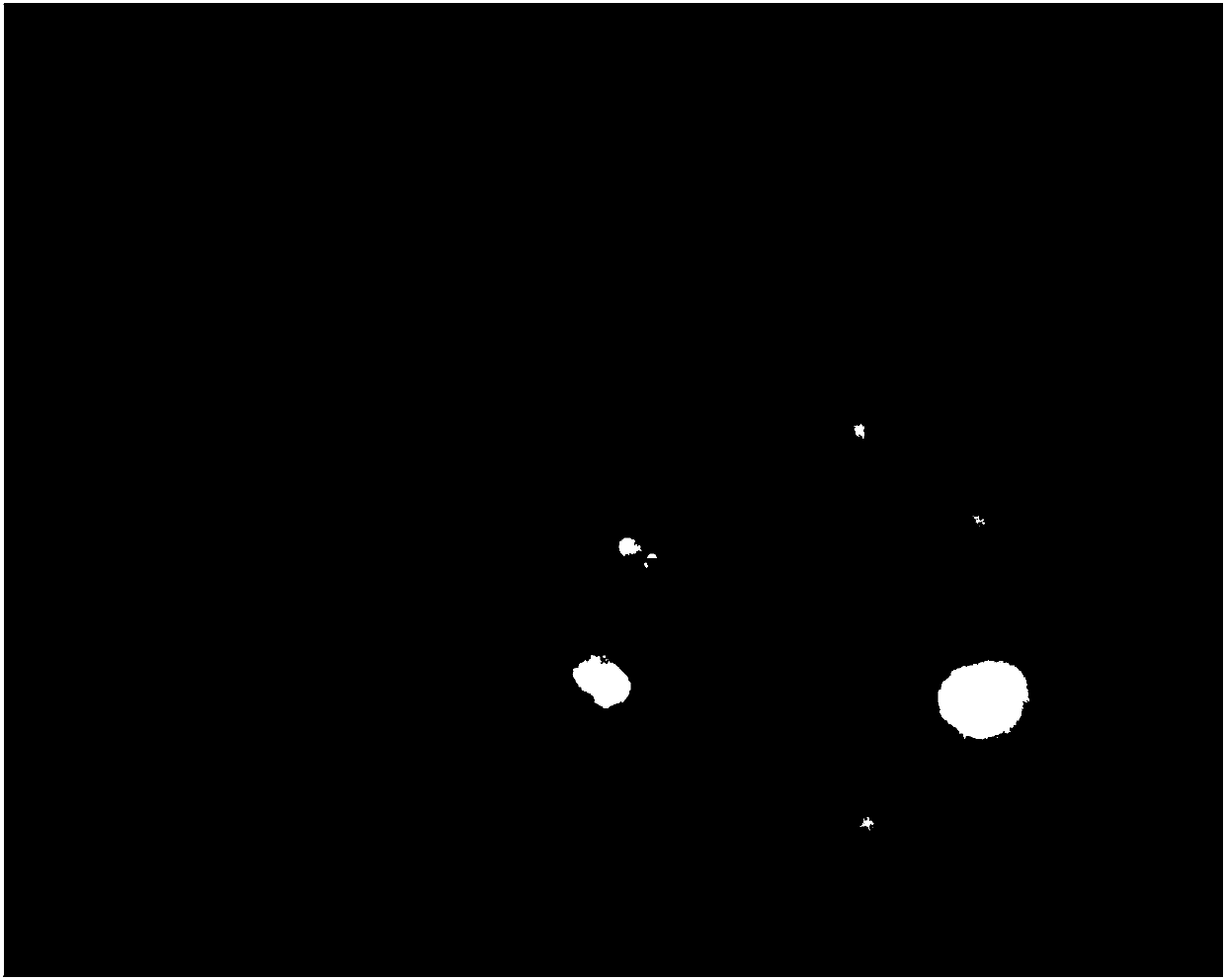

[0115] (1) Using the method described in "Entropy-based automatic threshold image segmentation method for identification of transmission line components" (invention patent, patent number: 2009101001689), the input furnace flame combustion color image I s Convert to grayscale image and perform threshold segmentation to get image I G0 .

[0116] (1.1) Convert the input color image to grayscale image I G ;

[0117] (1.2) For grayscale image I G First establish its grayscale histogram, and then establish the entropy histogram of the image based on the grayscale histogram; for each grayscale level, divide the corresponding number of pixels by the total number of pixels in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com