Mud turning airing device

A technology of overturning and silting, which is applied in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc. It can solve problems such as loss, slow deposition speed, and disasters to people's lives and property in the downstream, and achieve unique measures , scientific and reasonable design, novel idea effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now in conjunction with accompanying drawing, the present invention is described in detail:

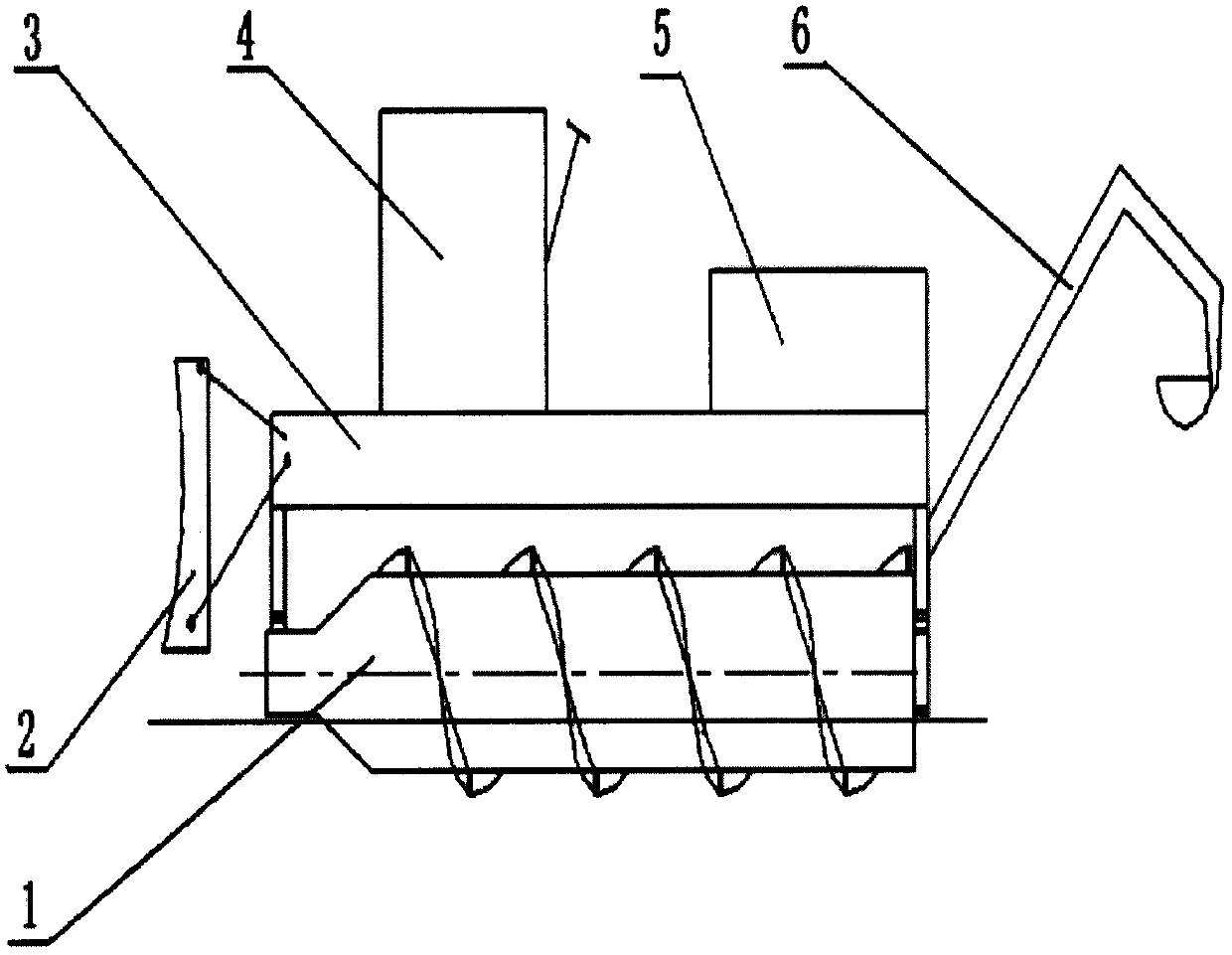

[0026] The invention is composed of a spiral buoy (1), a bucket (2), a hull (3), an engine (4), a transmission mechanism (5) and a bucket (6).

[0027] figure 1 Shown is the structural representation of the present invention. Wherein, 1 is a spiral buoy, 2 is a bucket, 3 is a hull, 4 is an engine, 5 is a transmission mechanism, and 6 is a bucket. The screw buoy (1) is placed on the bottom of the hull (3), the bucket (2) is placed on the front end of the hull (3), the engine (4) is placed on the hull (3), and the transmission mechanism (5) is placed on the hull (3). ), the bucket (6) is placed at the rear end of the hull (3), the transmission mechanism (5) is connected to the screw buoy (1) and controls its movement, the bucket (2) and the bucket (6) are driven by the engine ( 4) Kinetic energy generated and combined with artificial control of its motion.

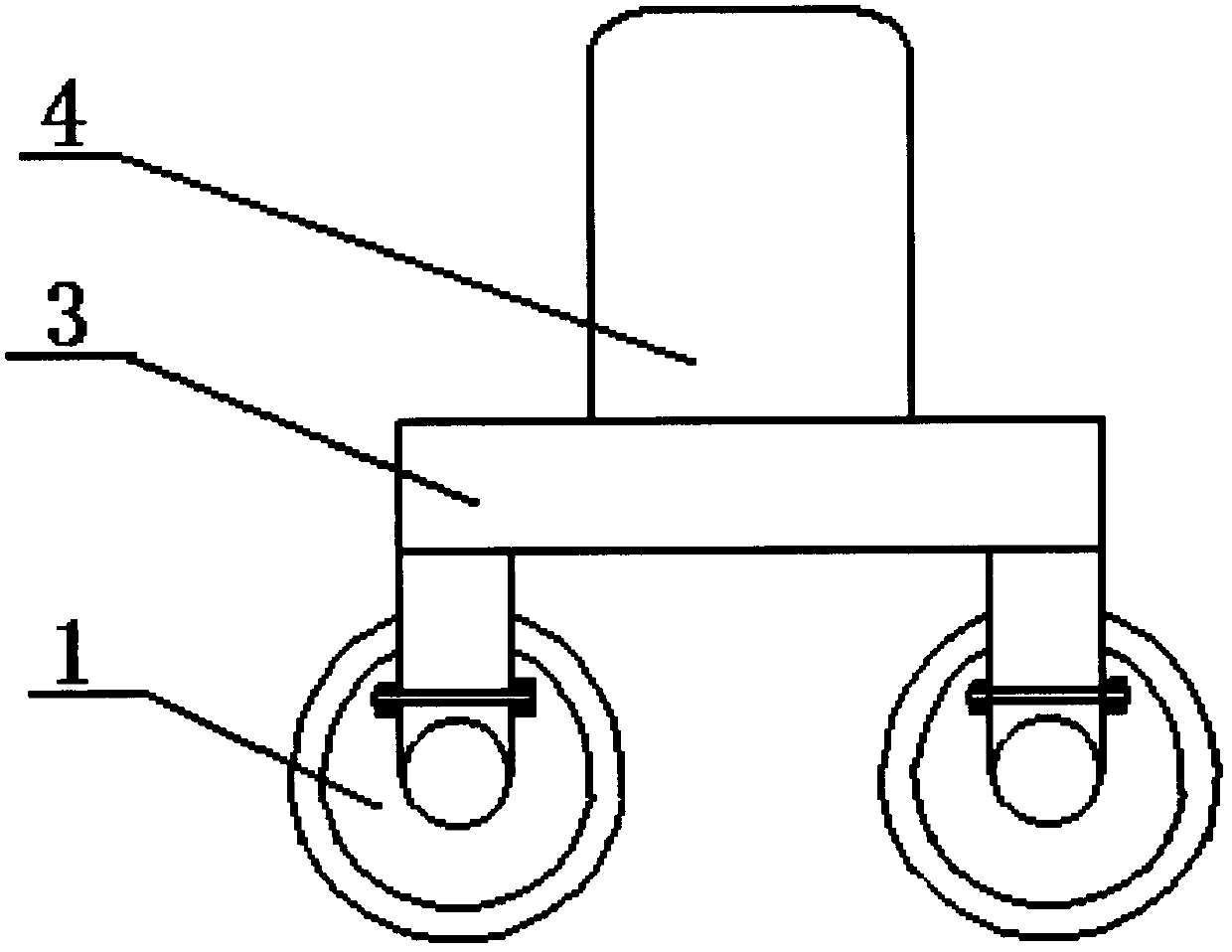

[0028] figure 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com