Subway shielding door lock with improved manual unlocking structure

A technology for manual unlocking and shielded doors, which is applied to handle connections, door/window accessories, building structures, etc., can solve the problems of automatic unlocking and easy misoperation, and achieve the effect of simple structure and preventing accidental touch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

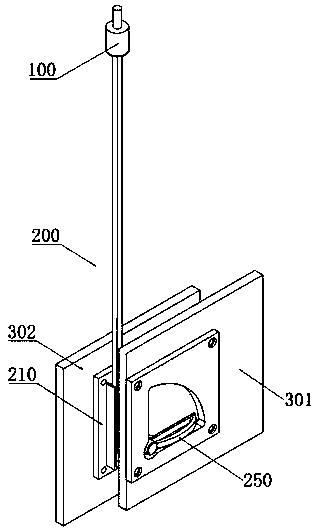

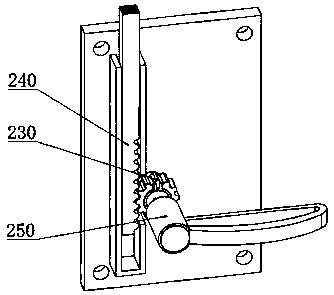

[0031] The present invention is realized in the following ways: as Figure 1-Figure 6 As shown, a subway screen door lock with an improved manual unlocking structure includes a lock body 100 that is vertically installed on the screen door and cooperates with the top box of the screen door to lock or unlock and a manual unlocking structure 200 connected to the lock body 100, The shielded door includes two A door panels 301 and B door panels 302 that are opposite and connected as one, and the lock body 100 is installed in the cavity formed by the A door panels 301 and B door panels 302; the manual unlocking structure 200 includes The support seat 210 fixedly installed on the inner wall of the B door panel 302 and the drive shaft 220, the wheel assembly 230, and the rack assembly 240 respectively installed on the support seat 210, the wheel assembly 230 driven by the drive shaft 220 and the drive shaft 230 installed on the lock body 100 The rack assembly 240 at the bottom end is ...

Embodiment 2

[0037]This embodiment is further optimized on the basis of the above-mentioned embodiments. The driving end of the handle 252 is provided with a limit protrusion; When the handle 252 is pulled out from the locking groove 2513 and rotated to the limit position along the unlocking groove 2512, the limiting block is in contact with the limiting protrusion, and at the same time, the rack assembly 240 moves down to a straight line The lowest end of the chute drives the lock body 100 to be completely unlocked through the manual unlocking structure 200 . In this embodiment, a limit protrusion and a limit hole are provided to add a limit guarantee, which can more effectively limit the rotation angle of the handle 252, unlock it quickly and accurately, and facilitate the return to the initial state later.

[0038] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

Embodiment 3

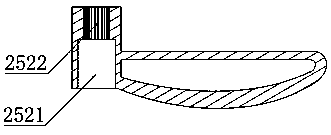

[0040] This embodiment is further optimized on the basis of the above embodiments, the length of the through hole 2521 is greater than the length of the inner spline groove 2522, and the end of the through hole 2521 without the inner spline groove 2522 is a smooth wall; the drive shaft 220 and The end connected to the driving end of the handle 252 is fixedly connected to the limit disk, and the linear movement range of the driving end of the handle 252 along the axis of the drive shaft 220 is limited within the length range of the external spline.

[0041] Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com