Electronically-controlled sucking and inflating type full sealed sliding window

A fully sealed, sliding window technology, which is applied in the field of sliding windows, can solve the problems of easily deformed window sash, laborious movement of sliding windows, and affecting the life of rubber hoses, etc., and achieve the effect of novel structure, flexible sliding and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

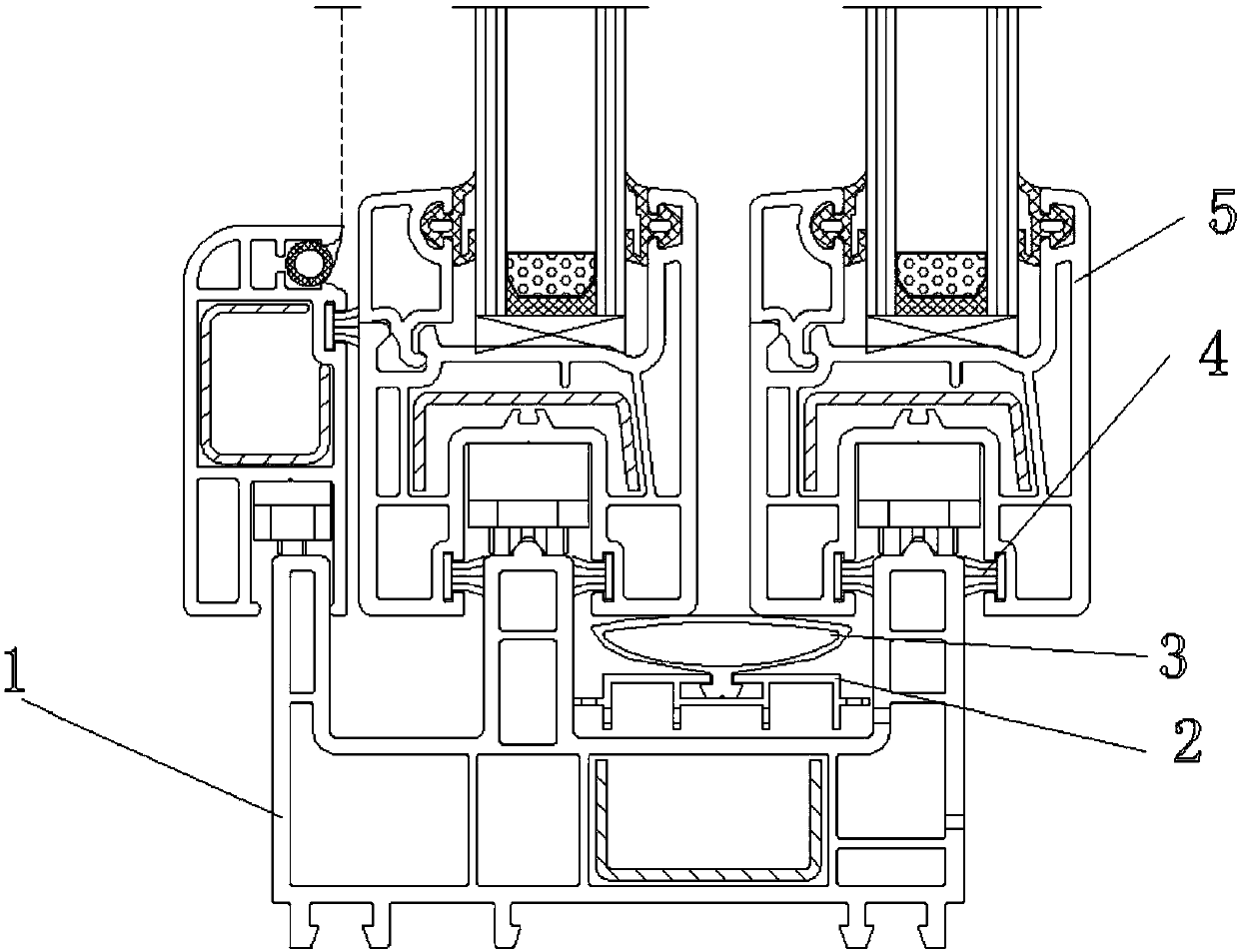

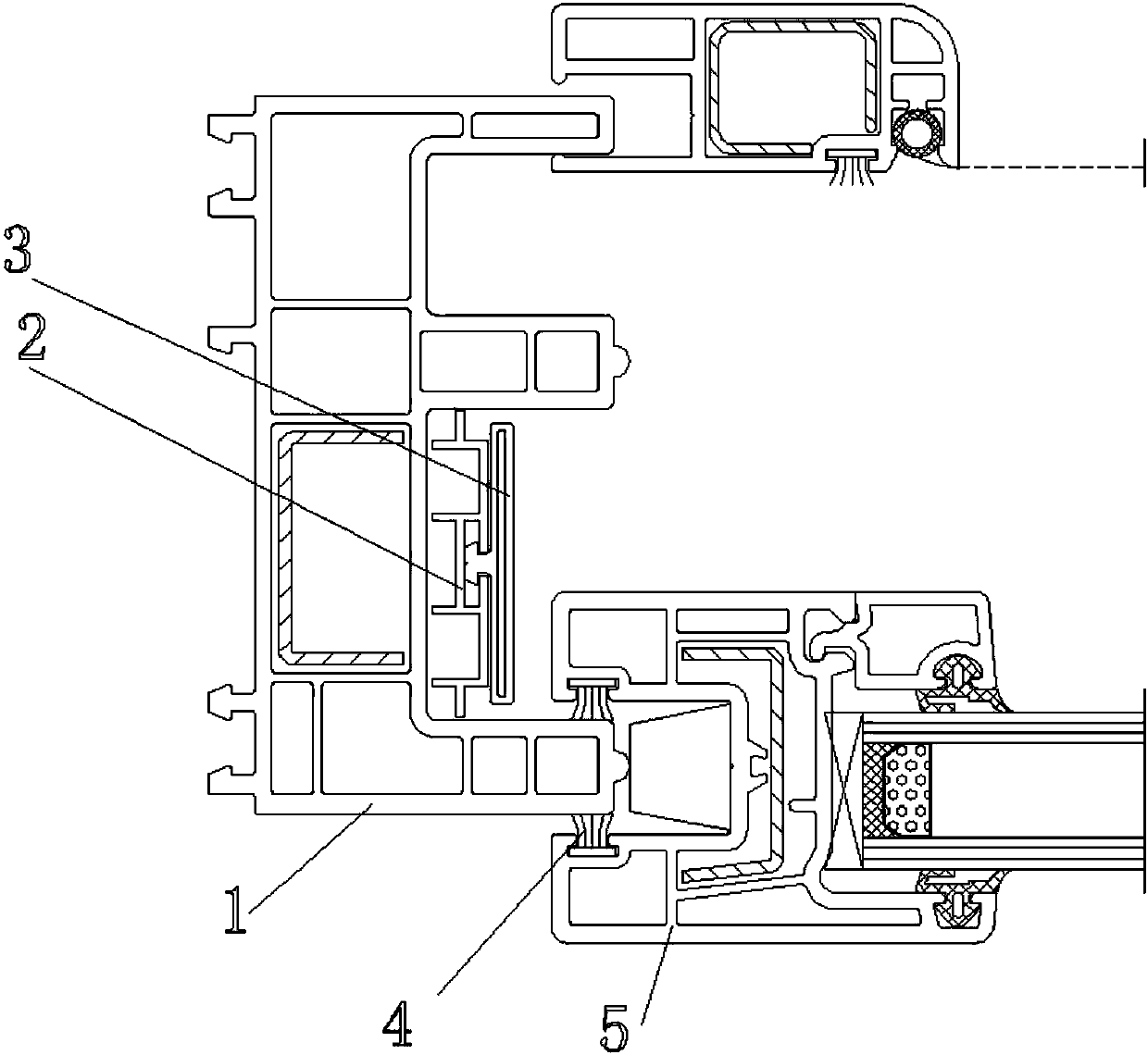

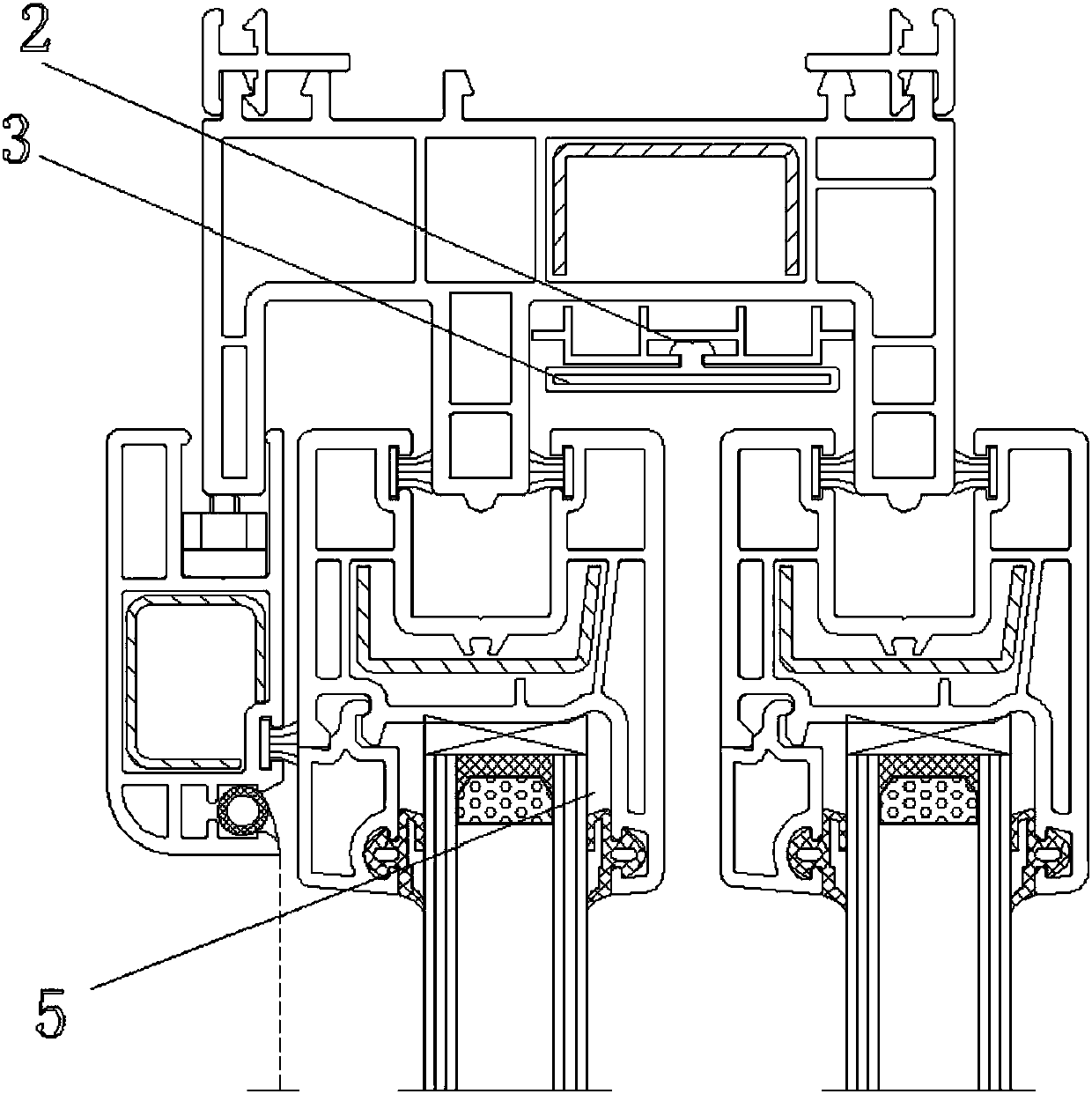

[0020] An electronically controlled suction-filled fully sealed sliding window, comprising a window frame 1 and a sliding fan 5, the window frame is an integral rectangular frame material composed of an upper sash profile, a lower sash profile, a left sash profile, and a right sash profile, Sliding fans include inner sliding fans and outer sliding fans, two or three fans, etc.

[0021] There is a frame fan sealing system between the window frame and the push-pull fan. The frame fan sealing system is provided with a continuous closed rubber hose ring 3 around the rectangular frame material. The rubber hose ring is connected with the suction and inflation electric control system through another connecting pipe to form a For a complete rubber hose system, when the suction and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com