Chuck seat with front-load air cylinder

A collet seat and front-mounted technology, which is applied in the direction of clamping, positioning devices, clamping devices, etc., can solve the problems of complex assembly process of the collet seat and the cylinder, shorten the service life of the collet seat, and high cost of use, and achieve overall Lightweight structure, good thread stability and strong rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

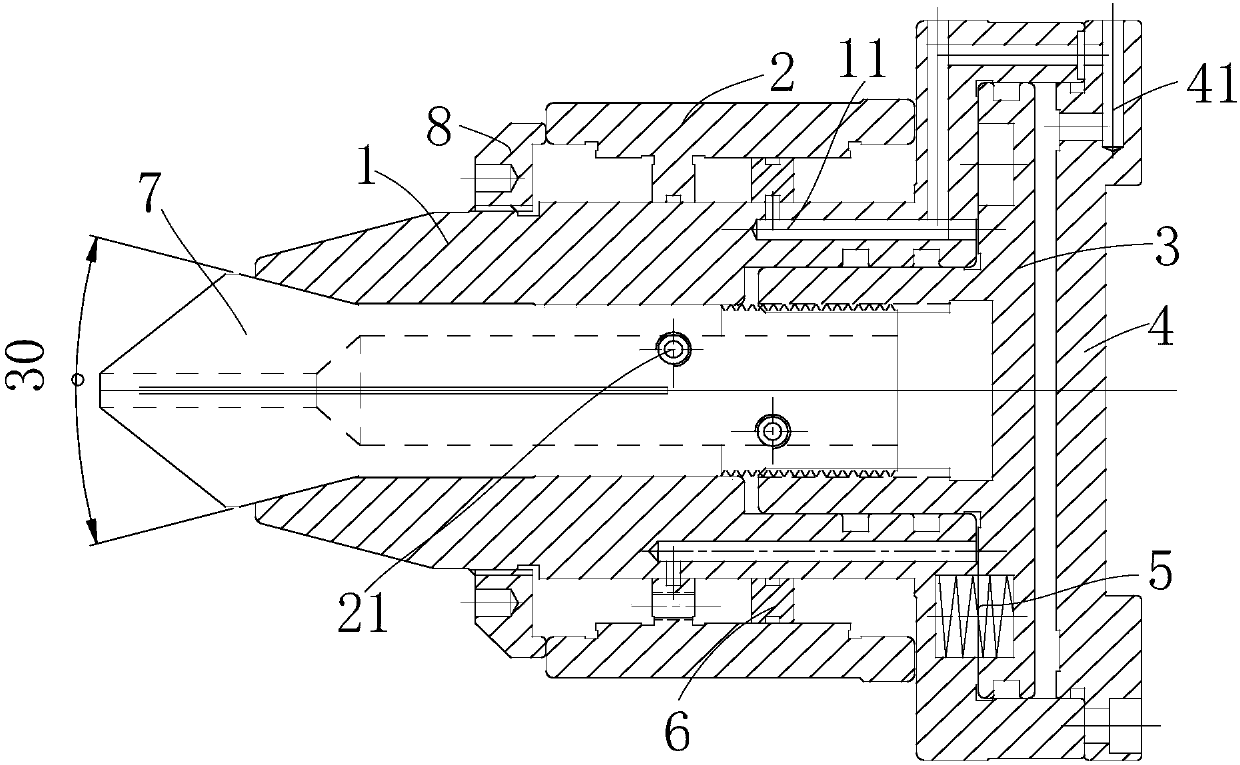

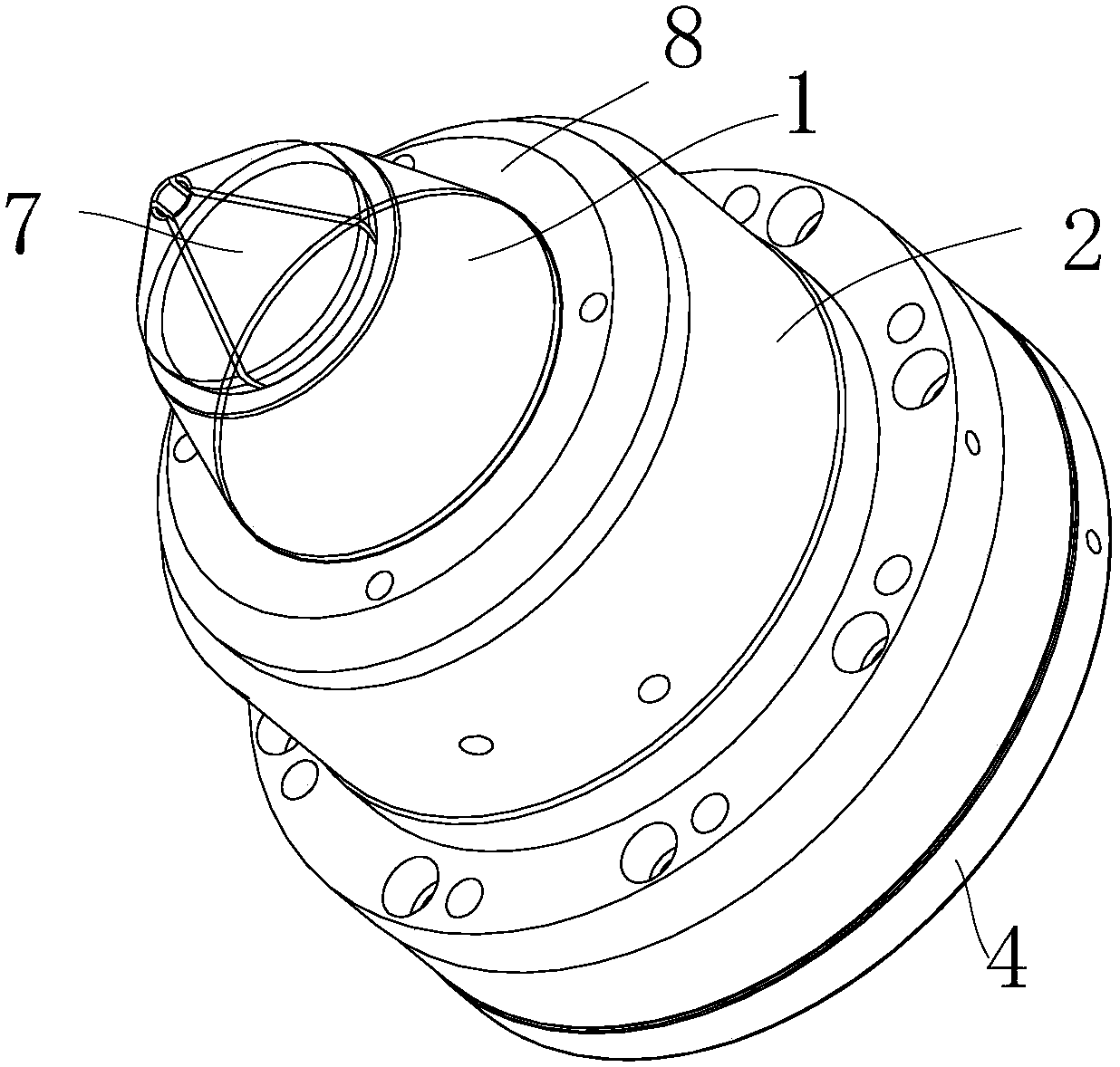

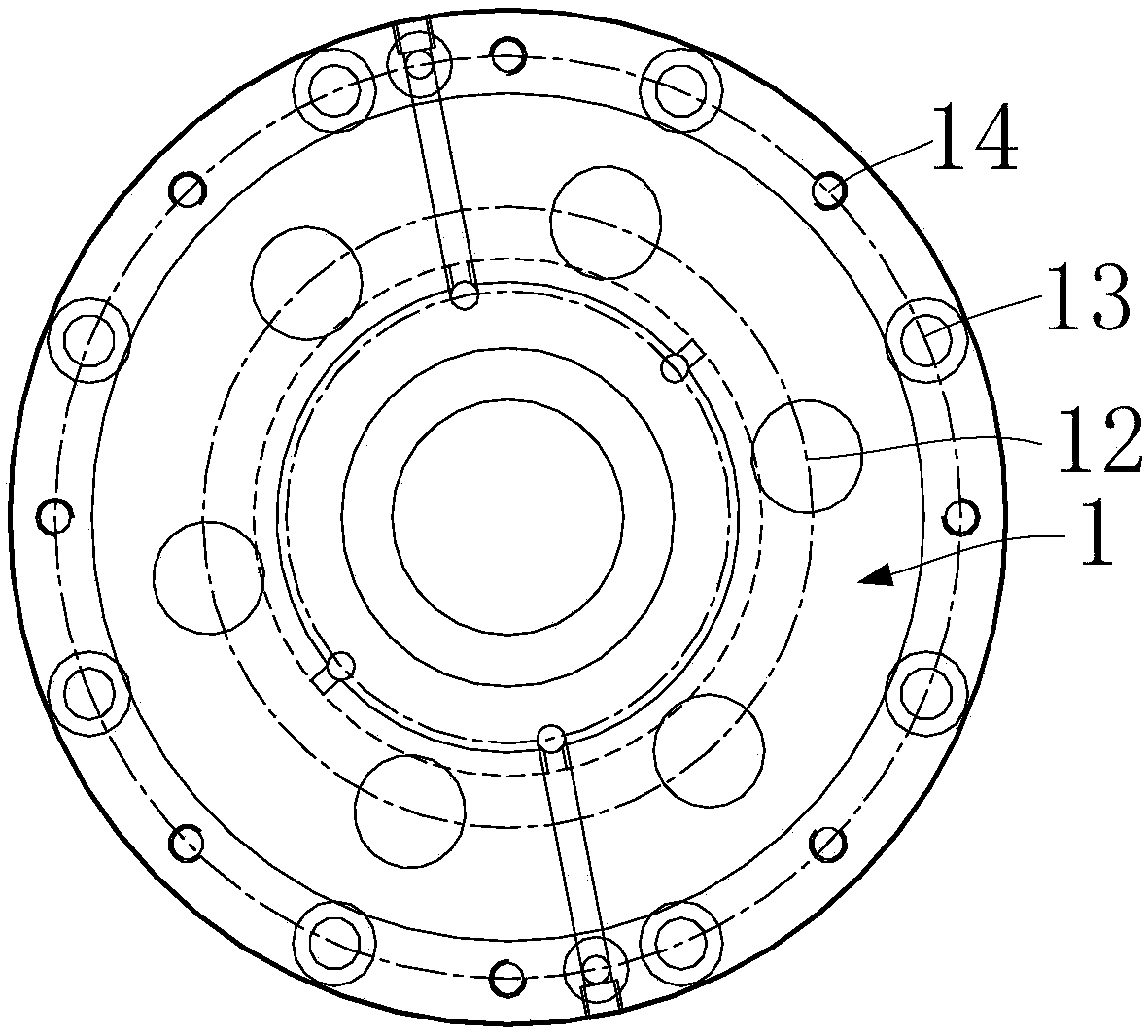

[0025] The above and other technical features and advantages of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present invention, not all of them.

[0026] The invention provides a front-mounted cylinder chuck seat. The traditional front-mounted cylinder chuck seat is formed by installing a separate chuck seat and a rear-mounted cylinder, but the traditional rear-mounted cylinder has high pretense costs, complicated assembly process, and needs to be connected with a flange and a tie rod during assembly. It is difficult to achieve high precision. In addition, the rear-mounted cylinder takes up a lot of space and is heavy, which affects the running performance of the machine, resulting in a short service life of the chuck seat and high use costs. The present invention integrates the air cylinder and the chuck seat into one, so that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com