Plastic solution mixing and de-foaming method

A glue and defoaming technology, which is used in the field of plastic glue mixing and defoaming, can solve the problems of stickiness, affecting the quality of rubber products, and difficulty in removing bubbles by themselves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

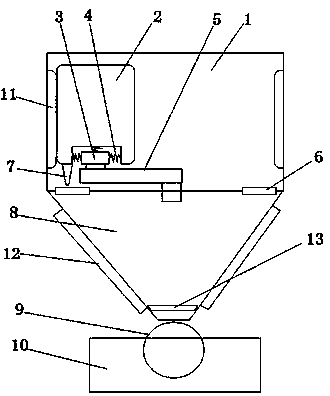

[0015] Such as figure 1 As shown, the device used in a method for mixing and defoaming plastic glue of the present invention includes a stirring device and a defoaming device. The glue is thinned, exposing the bubbles in it, and accelerating the bursting of the bubbles;

[0016] Described mixing device comprises the barrel-shaped body 1 that top is opening, is provided with drum 2 in the barrel-shaped body 1, has groove at the bottom of described drum 2, is provided with movable block 3 in the groove, and the movable block 3 A spring 4 is arranged between one week and the inner wall of the groove at the bottom of the drum 2, and a connecting rod 5 is arranged between the movable block 3 and the inner bottom of the barrel 1. The connecting rod 5 is provided with two pin shafts, and the two pin shafts Both are perpendicular to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com