Embracing hoop device based on triangular structure

A triangular structure and hoop plate technology, applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems affecting the connection and sealing effect of new pipe sections, unable to ensure the stability of oil pipelines, unable to guarantee the leveling and other problems , to avoid friction damage, enhance stability and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order for those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and the following embodiments.

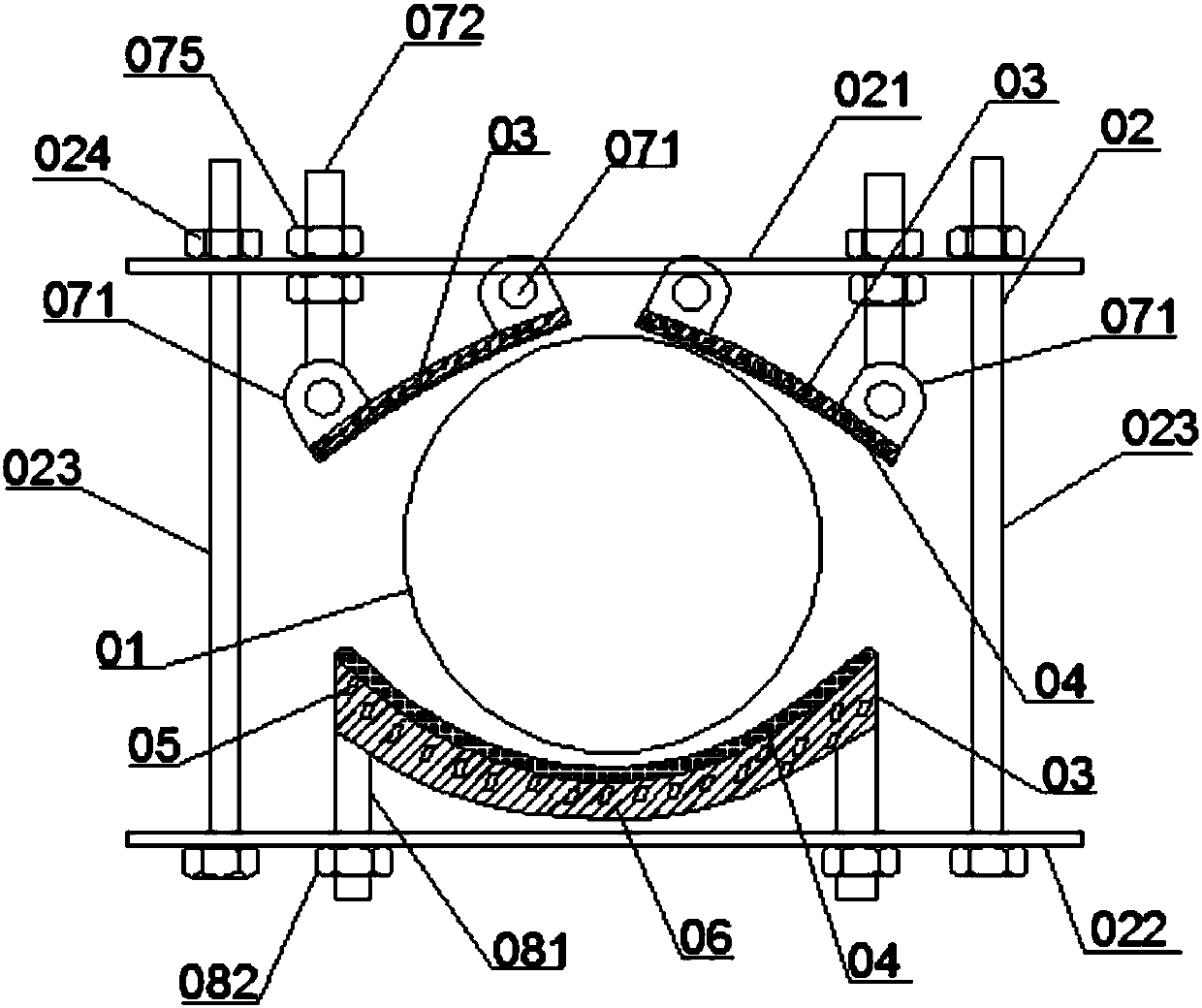

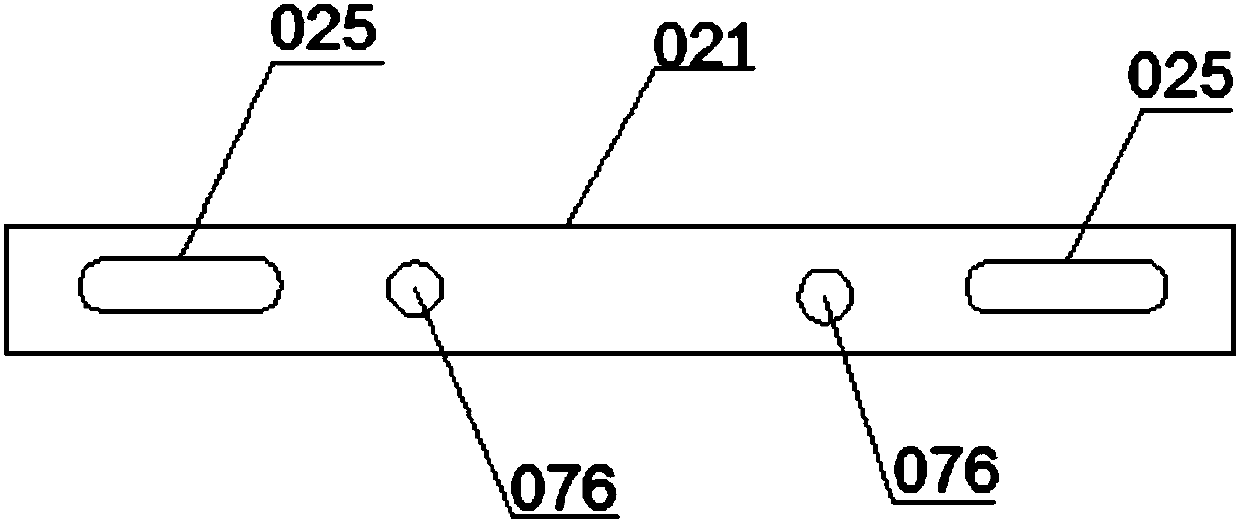

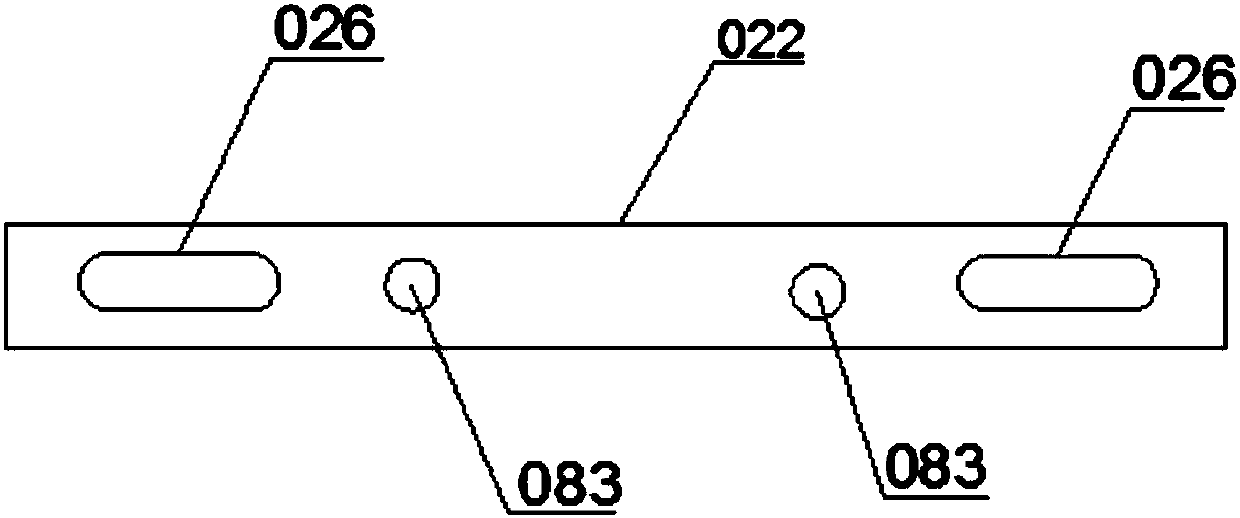

[0027] Please refer to Figure 1 to Figure 4 As shown, this embodiment provides a hoop device based on a triangular structure, including a support mechanism 02 for hugging the periphery of the oil pipeline 01, and an adjustment assembly for adjusting the distance between the support mechanisms 02 and locking them Specifically, the support mechanism 02 includes an upper support plate 021 and a lower support plate 022, and the adjustment assembly includes two locking screws 023 and lock nuts 024 vertically connected between the upper support plate 021 and the lower support plate 022, and the upper The support plate 021 and the lower support plate 022 are respectively provided with a first strip-shaped hole 025 and a second strip-shaped hole 026 . Uti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com