New energy vehicle chassis load testing device

A new energy vehicle and load testing technology, which is applied in the direction of measuring devices, vehicle testing, machine/structural component testing, etc., can solve problems such as simulation of complex road conditions that cannot meet complex operating conditions, and achieve high test reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

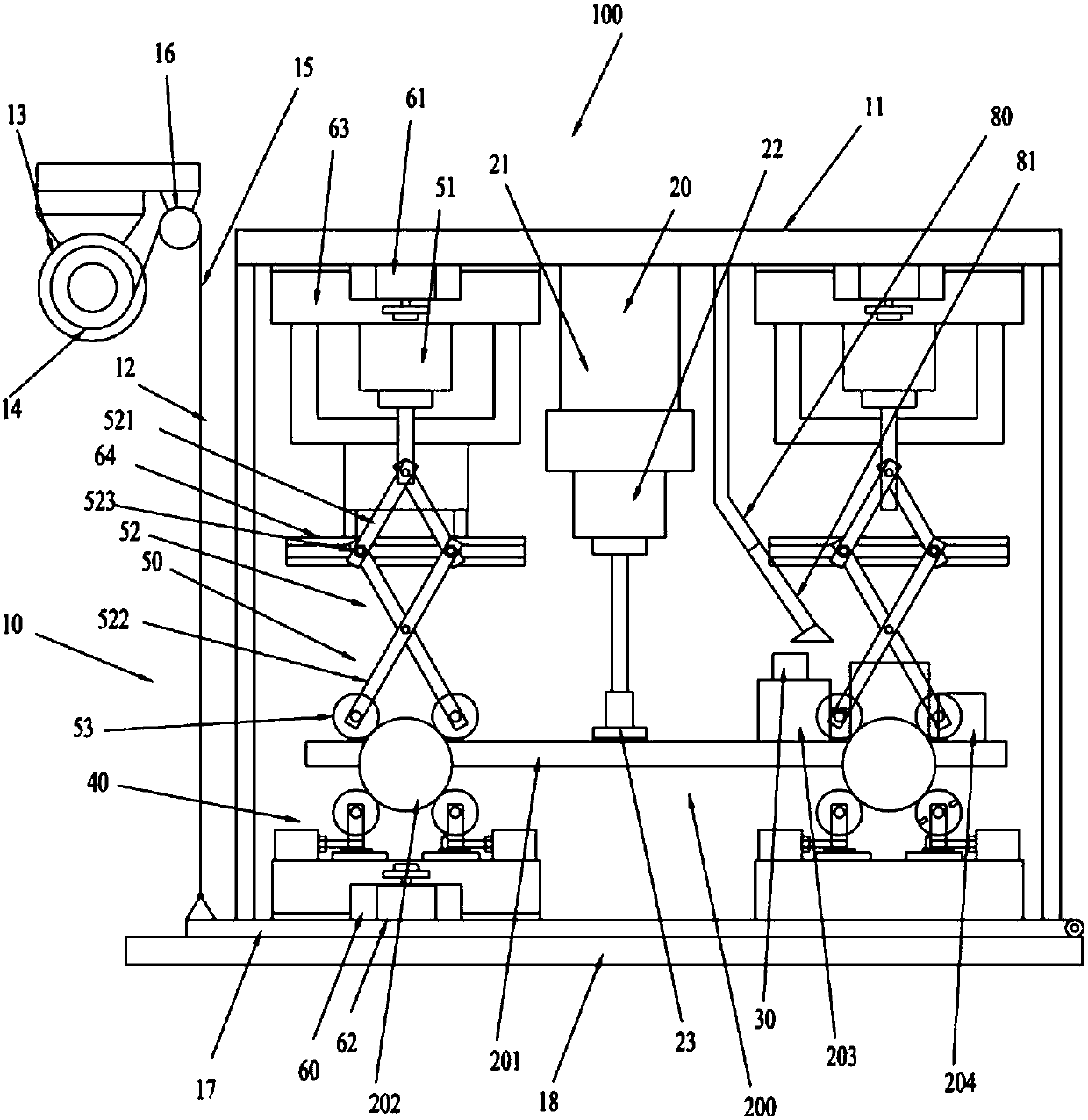

[0036] Such as Figure 1 to Figure 7 As shown, 1. A new energy vehicle chassis load test device 100, comprising: a slope simulation test device 10, a load-bearing simulation test device 20 and a motor power detection device 30.

[0037] The slope simulation test device 10 simulates the driving conditions of the new energy vehicle 200 on different slopes by adjusting the posture of the new energy vehicle chassis 201 .

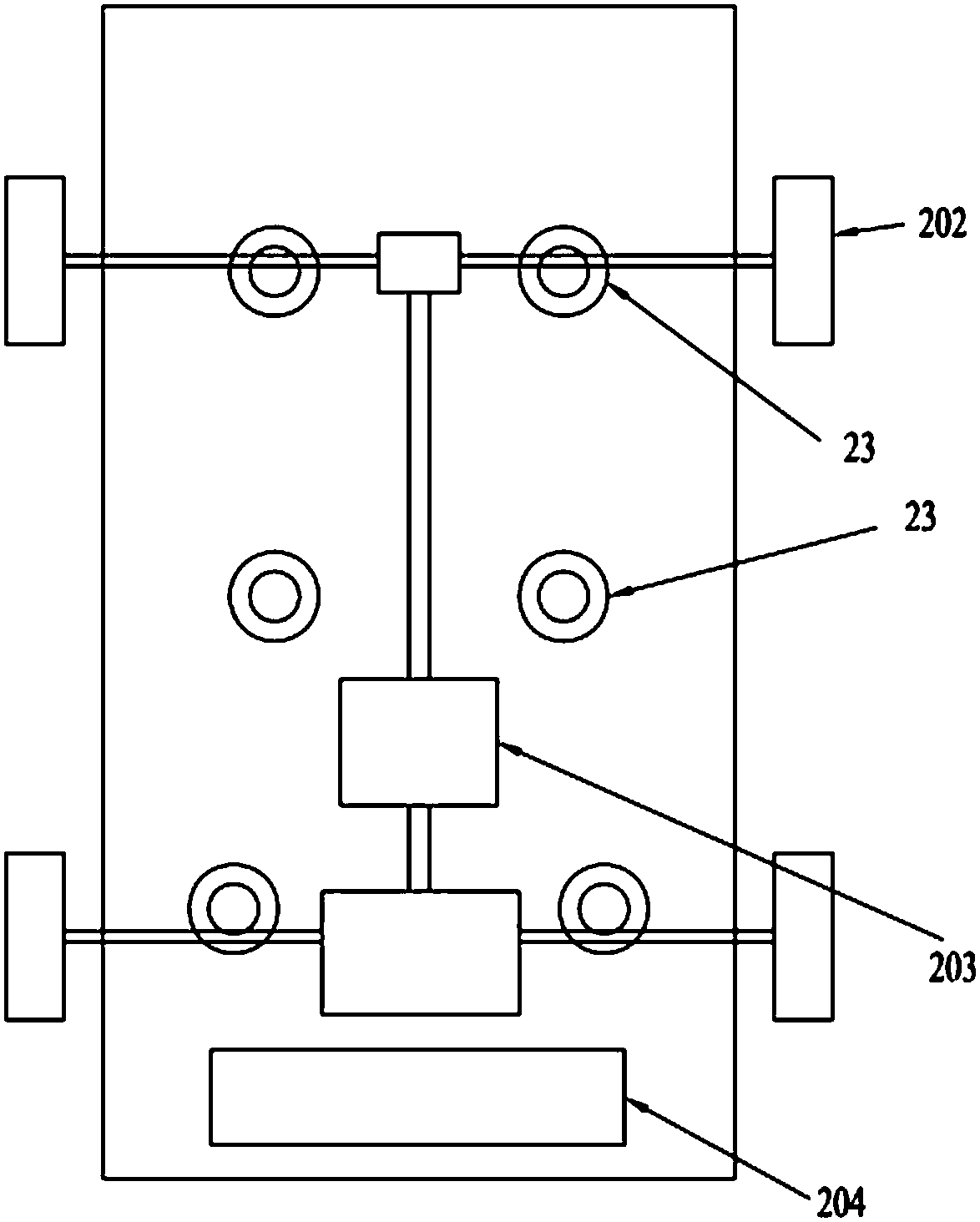

[0038] The load-bearing simulation test device 20 adjusts the pressure on different areas of the new energy vehicle chassis 201 to simulate the working conditions when the new energy vehicle 200 bears different loads as a whole and different areas bear deflected loads.

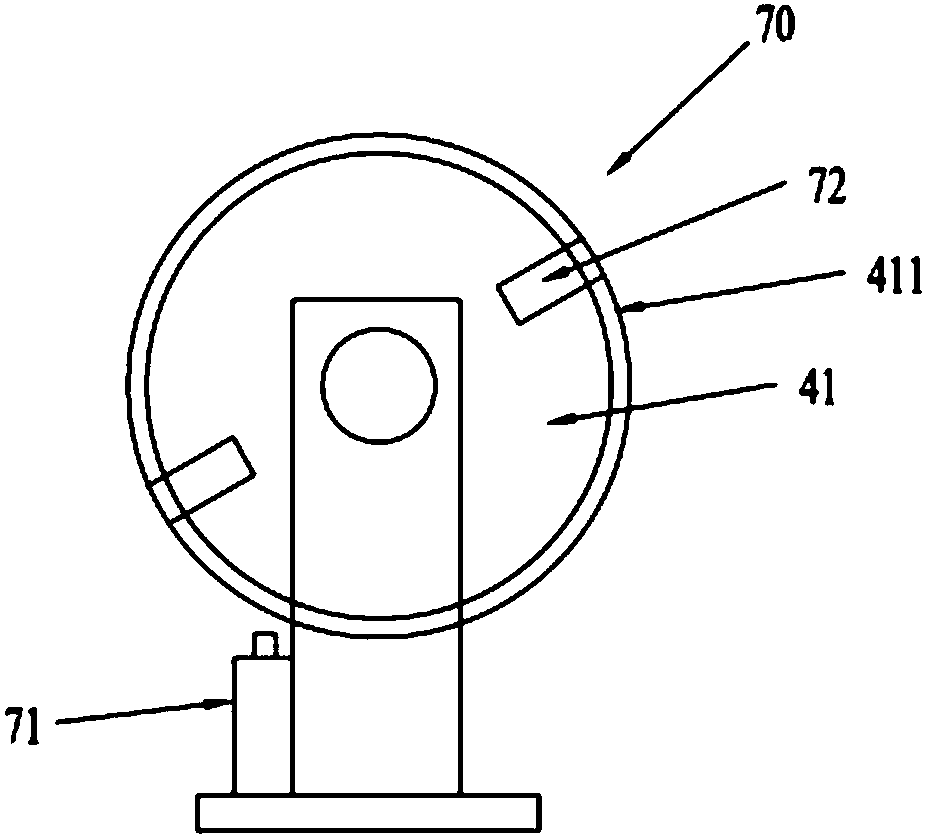

[0039] The motor power detection device 30 is used to detect the power of the motor 203 of the new energy vehicle 200 in real time. The motor power detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com