A Corrosion Method for Measuring Grain Size of Ultra-thin Stainless Steel

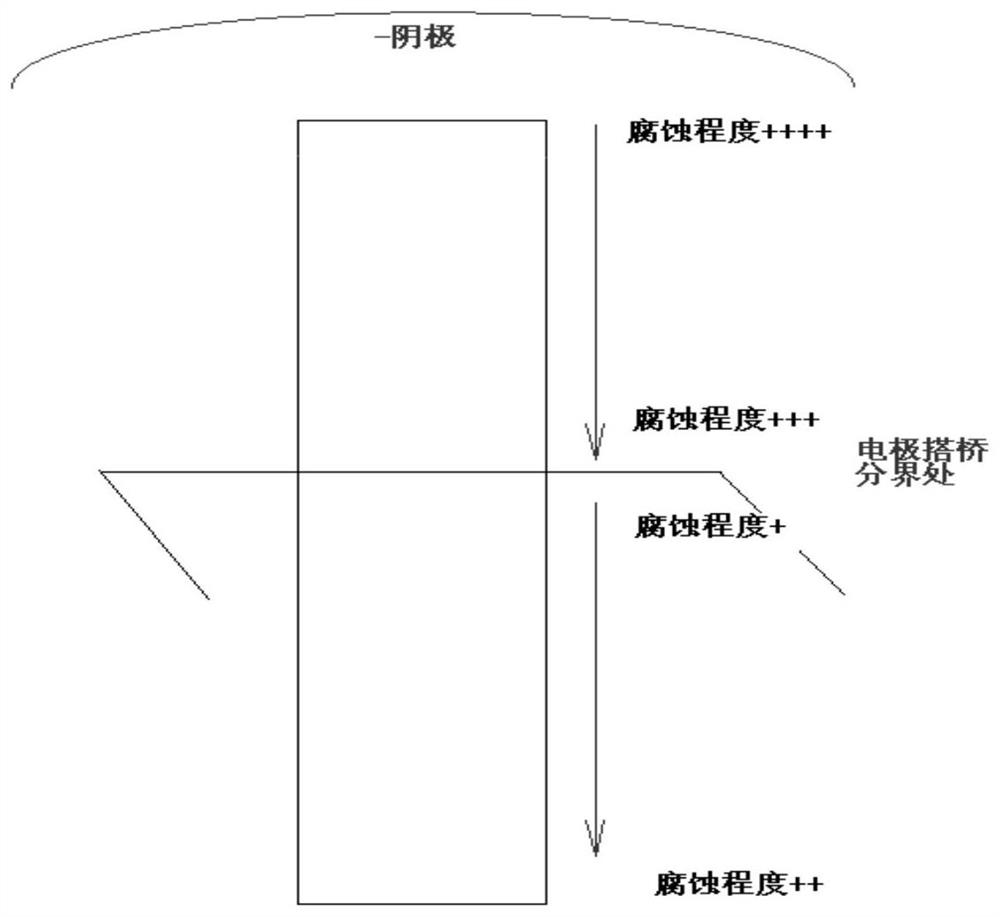

A stainless steel, grain size technology, applied in the field of metallographic corrosion, can solve the problems of repeated grinding corrosion, corrosion not in place, excessive corrosion, etc., to achieve the effect of reducing duplication of labor, process adjustment and improvement, and reducing the occurrence of twins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Take a section of sample from 300 grade ultra-thin stainless steel, and trim the surface to be tested by wire cutting (generally sliced samples, there will be a section of deformation area on the end surface, if the grinding is not enough, the test area will be inaccurate, resulting in test errors ). Then cut into about 25mm width samples.

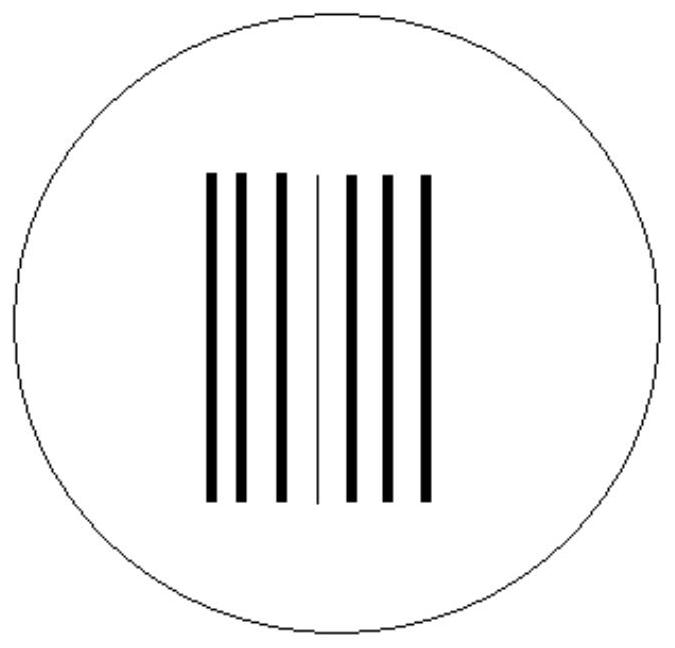

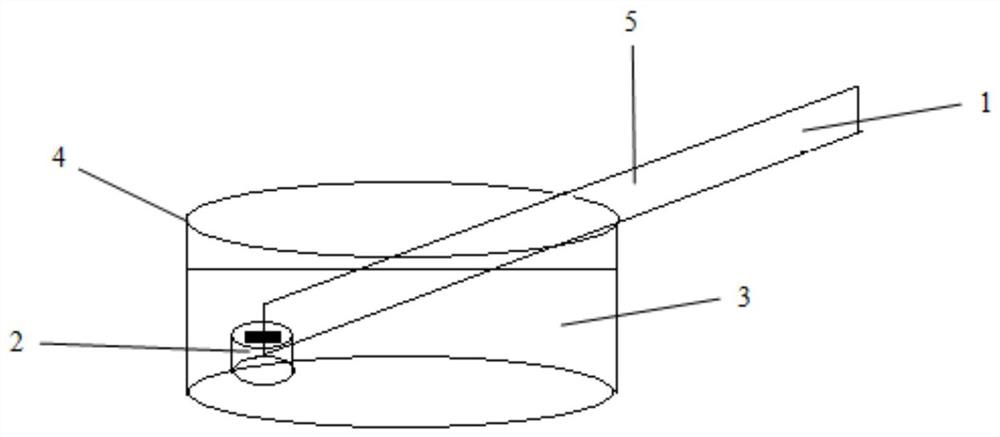

[0025] (2) Clamp the sample to be tested (the sample and the sample to be tested are preferably both 300 series stainless steel) in the middle position with 3 samples of about 2 mm on the left and right sides, and ensure that the test end faces are aligned (which can reduce the grinding time), such as figure 1 Shown, placed in a cold mounting tool.

[0026] (3) Take 5mL and 10ml of the two liquids of epoxy resin and curing agent according to the volume ratio of 1:2, then mix the two liquids, and then slowly stir clockwise for 2 minutes (to minimize the generation of air bubbles), and then pour into Cold Mounting in Abrasive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com