Processing method of long-acting slow release mosquito repellent paster

A processing method and technology for mosquito repellent stickers, which are applied in the fields of botanical equipment and methods, pest repellents, animal repellents, etc., can solve the problem that the mosquito repellent stickers have short repellent effect, low safety, and cannot function as a repellent normally. Mosquito effect and other issues, to achieve the effect of maintaining the mosquito repellent effect and improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Processing of long-acting slow-release mosquito repellent patch:

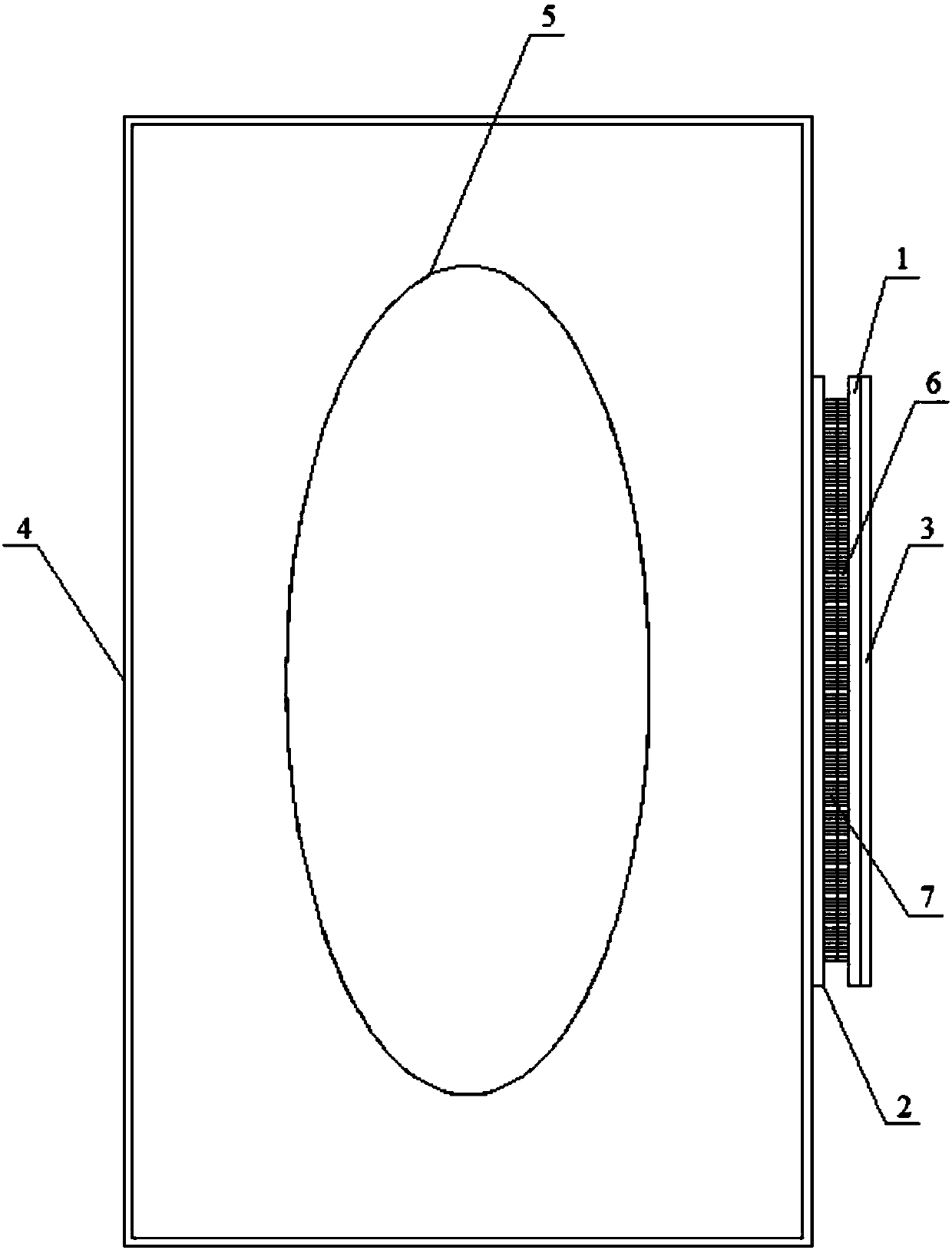

[0031] (1) The structure construction of mosquito repellent patch: as figure 1 As shown, the mosquito repellent patch includes an adhesive part and a drug-loaded part. The adhesive part is made of a backing base cloth 1, a drug-loaded connecting cloth 2 and an adhesive film 3, and the drug-loaded part is made of a non-woven fabric 4 and a mosquito repellent sheet 5. The adhesive film is attached to the back of the adhesive base cloth, the front of the adhesive base cloth is provided with an adhesive hook surface 6, and the front of the drug-loaded connection cloth is provided with an adhesive suede surface 7 that matches the adhesive hook surface, and the drug-loaded connection The cloth is attached to the non-woven fabric by sewing;

[0032] (2) Preparation of mosquito repellent sheet: add 5g mosquito repellent to 35g carrier, send in the tablet press machine after fully mixing, be pressed into the she...

Embodiment 2

[0040] Processing of long-acting slow-release mosquito repellent patch:

[0041] (1) The structure construction of mosquito repellent patch: as figure 1As shown, the mosquito repellent patch includes an adhesive part and a drug-loaded part. The adhesive part is made of a backing base cloth 1, a drug-loaded connecting cloth 2 and an adhesive film 3, and the drug-loaded part is made of a non-woven fabric 4 and a mosquito repellent sheet 5. The adhesive film is attached to the back of the adhesive base cloth, the front of the adhesive base cloth is provided with an adhesive hook surface 6, and the front of the drug-loaded connection cloth is provided with an adhesive suede surface 7 that matches the adhesive hook surface, and the drug-loaded connection The cloth is attached to the non-woven fabric by sewing;

[0042] (2) Preparation of mosquito repellent sheet: add 5g mosquito repellent to 45g carrier, send in the tablet press machine after fully mixing, be pressed into the shee...

Embodiment 3

[0050] Processing of long-acting slow-release mosquito repellent patch:

[0051] (1) The structure construction of mosquito repellent patch: as figure 1 As shown, the mosquito repellent patch includes an adhesive part and a drug-loaded part. The adhesive part is made of a backing base cloth 1, a drug-loaded connecting cloth 2 and an adhesive film 3, and the drug-loaded part is made of a non-woven fabric 4 and a mosquito repellent sheet 5. The adhesive film is attached to the back of the adhesive base cloth, the front of the adhesive base cloth is provided with an adhesive hook surface 6, and the front of the drug-loaded connection cloth is provided with an adhesive suede surface 7 that matches the adhesive hook surface, and the drug-loaded connection The cloth is attached to the non-woven fabric by sewing;

[0052] (2) Preparation of mosquito repellent sheet: add 5g mosquito repellent to 35g carrier, send in the tablet press machine after fully mixing, be pressed into the she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com