Disposable shoe cover suitable for mechanical production

A disposable and shoe cover technology, applied in the direction of footwear, etc., can solve the inconvenience of mechanized production and other problems, and achieve the effect of simple structure, suitable for mechanized mass production, and ideal use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

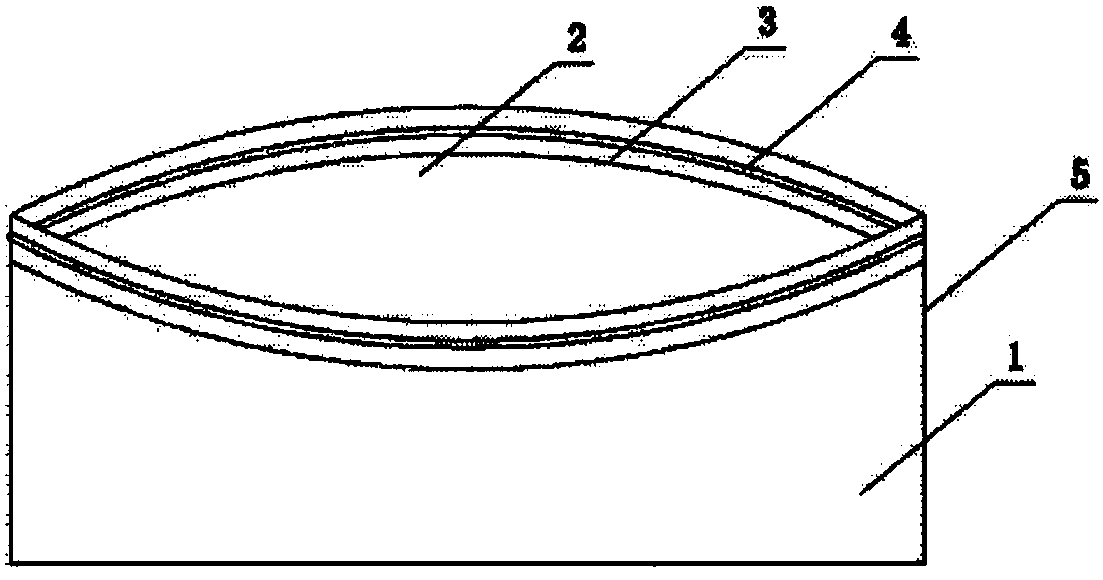

[0015] Embodiment 1: as figure 1 As shown, a disposable shoe cover suitable for mechanized production includes a cover body 1, and the cover body 1 is made of a plastic film.

[0016] The sleeve body 1 is a bag-shaped structure formed by folding a plane through the middle and sewing the vertical sides 5 on both sides; The transverse sides 3 are folded inward to form flanging respectively, and the flangings are covered with elastic bands 4 .

[0017] Practical: Take the conventional reel fabric, and spread it out into strips (satisfying the rectangular structure). First, place an elastic band at 15mm from the edge of both sides, then apply glue on the surface, and wrap it along the edge of the elastic band after gluing Fold back to form a flanging, send it to the next process to compact the upper and lower sizing surfaces, then fold the fabric in half along the symmetrical center line of the two flangings, and finally cut a section according to the length of the shoe cover, an...

Embodiment 2

[0018] Embodiment 2: The cover body 1 is made of composite non-woven fabric. All the other are with embodiment 1.

[0019] Practical: Take the conventional reel fabric, and spread it out into strips (satisfying the rectangular structure). First, place an elastic band at 15mm from the edge of both sides, then apply glue on the surface, and wrap it along the edge of the elastic band after gluing Fold back to form a flanging, send it to the next process to compact the upper and lower sizing surfaces, then fold the fabric in half along the symmetrical center line of the two flangings, and finally cut a section according to the length of the shoe cover, and seal and cut both sides with glue or needle thread edge, so that the two sides of the flange are connected end to end, and the whole is a bag-like body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com