Preparation method and application of carbon quantum dot/metal organic skeleton catalyst

A metal-organic framework, carbon quantum dot technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, catalytic reactions, etc., can solve problems such as low activity, and achieve a simple synthesis process, Highly maneuverable, easy-to-adjust effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0024] Example 1:

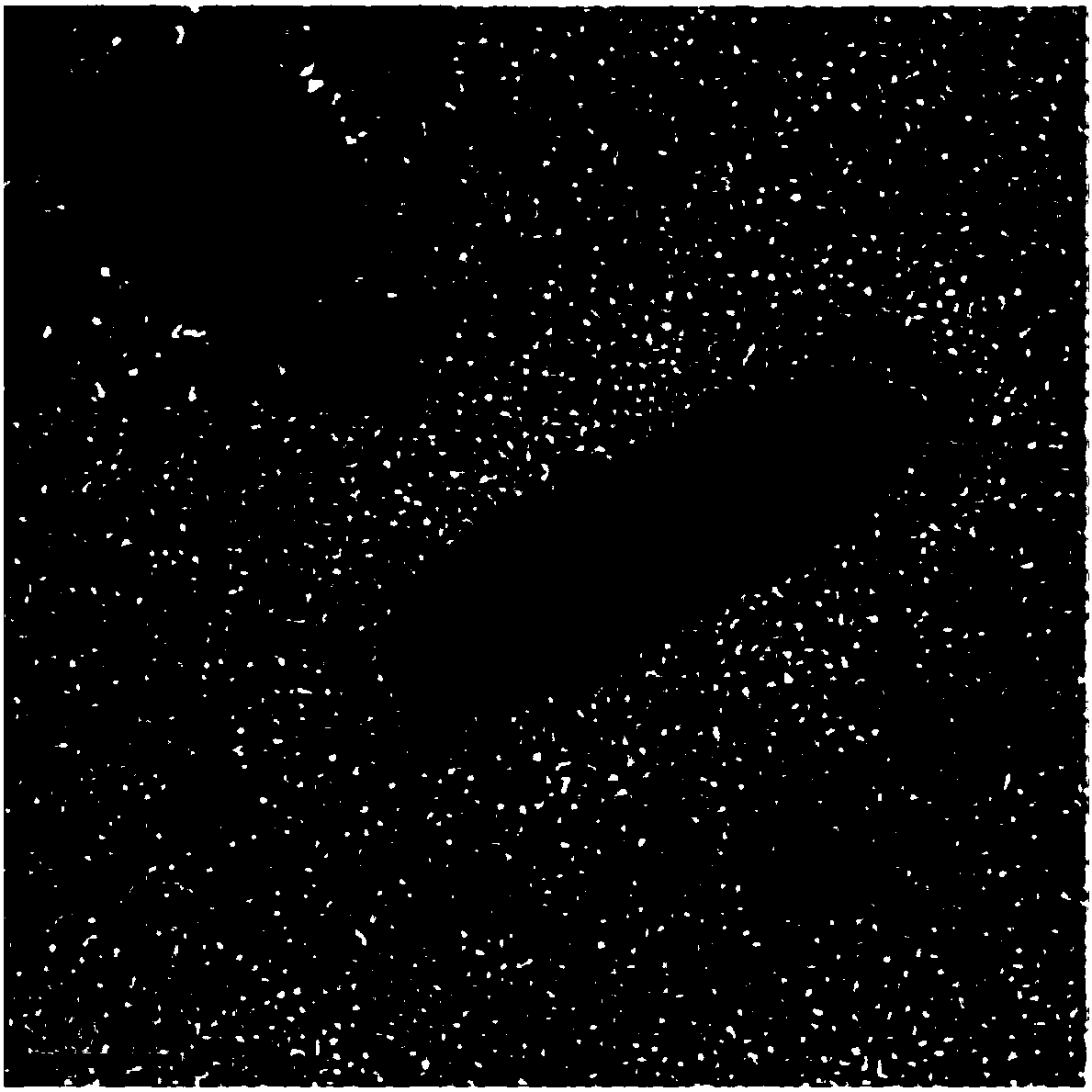

[0025] (1) Preparation of carbon quantum dots:

[0026] Add 500 mL of deionized water to a 500 mL beaker, put two graphene electrodes into the above beaker with a distance of 7 cm, and apply 30V direct current. After two weeks of electrolysis, the clear and colorless water becomes a black aqueous solution. After filtering the black aqueous solution with filter paper, it was centrifuged at a speed of 20,000 rpm for one hour, and the supernatant was taken. The supernatant is dried by rotary evaporation to obtain the required carbon quantum dots.

[0027] (2) Preparation of aqueous solution of carbon quantum dots:

[0028] Take 25 mg of carbon quantum dots and add 5 mL of water to obtain a 0.5 mg / mL solution.

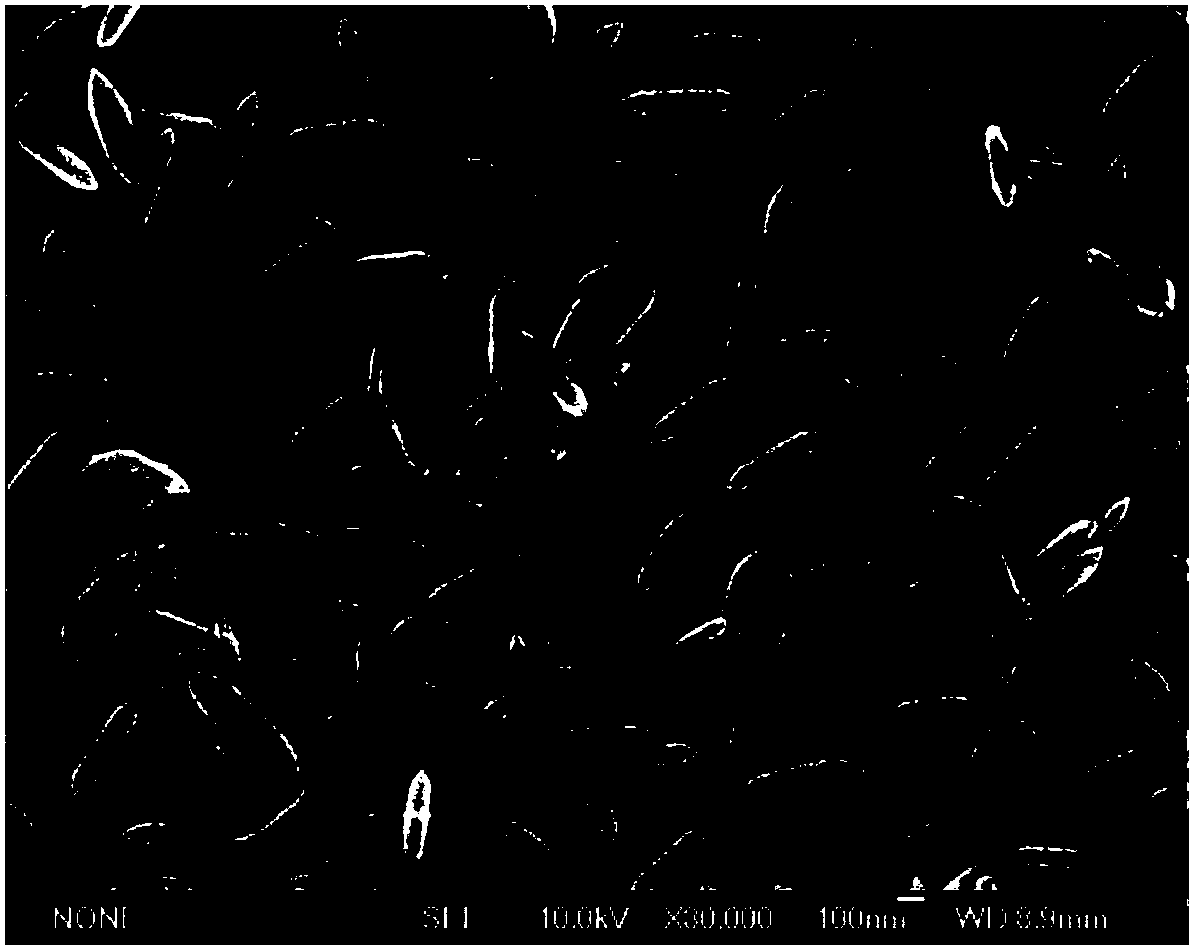

[0029] (3) Catalyst NH 2 -Preparation of MIL-88(Fe):

[0030] 0.32 g of surfactant F127 was dissolved in 26.7 mL of deionized water, and 3.3 mL of 0.4 M ferric chloride aqueous solution was added to the above solution, and stirred for 1.5 hours. Then 0.6 mL of ...

Example Embodiment

[0034] Example 2:

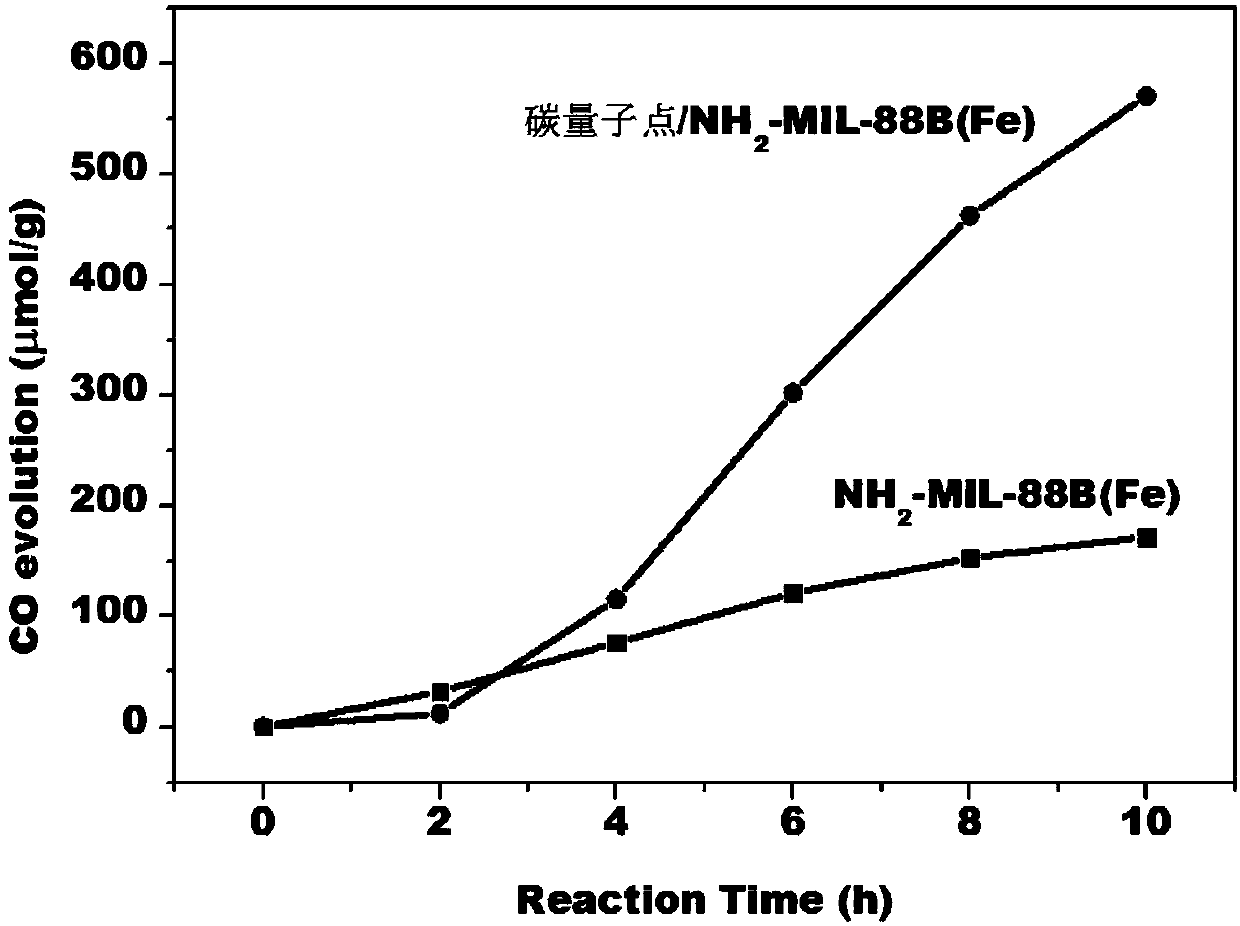

[0035] NH 2 -MIL-88(Fe) catalyst photocatalytic reduction of CO 2 Performance evaluation: take 10mg NH 2 -MIL-88(Fe) catalyst is uniformly dispersed on the quartz filter membrane, placed in a solid-gas photocatalytic reaction device, and 2mL of a mixture of acetonitrile and triethanolamine (the volume ratio of acetonitrile to triethanolamine is 4:1) Vacuum and charge CO 2 After that, the reaction was allowed to equilibrate in a dark environment for 1 hour. Subsequently, the reaction device was placed under a 300W visible light lamp, and the CO concentration was measured every two hours.

Example Embodiment

[0036] Example 3:

[0037] Carbon quantum dot / NH 2 -MIL-88(Fe) photocatalytic reduction of CO 2 Performance evaluation: take 10mg carbon quantum dots / NH 2 -MIL-88(Fe) catalyst is uniformly dispersed on the quartz filter membrane, placed in a solid-gas photocatalytic reaction device, and 2mL of a mixture of acetonitrile and triethanolamine (the volume ratio of acetonitrile to triethanolamine is 4:1) Vacuum and charge CO 2 After that, the reaction was allowed to equilibrate in a dark environment for 1 hour. Subsequently, the reaction device was placed under a 300W visible light lamp, and the CO concentration was measured every two hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com