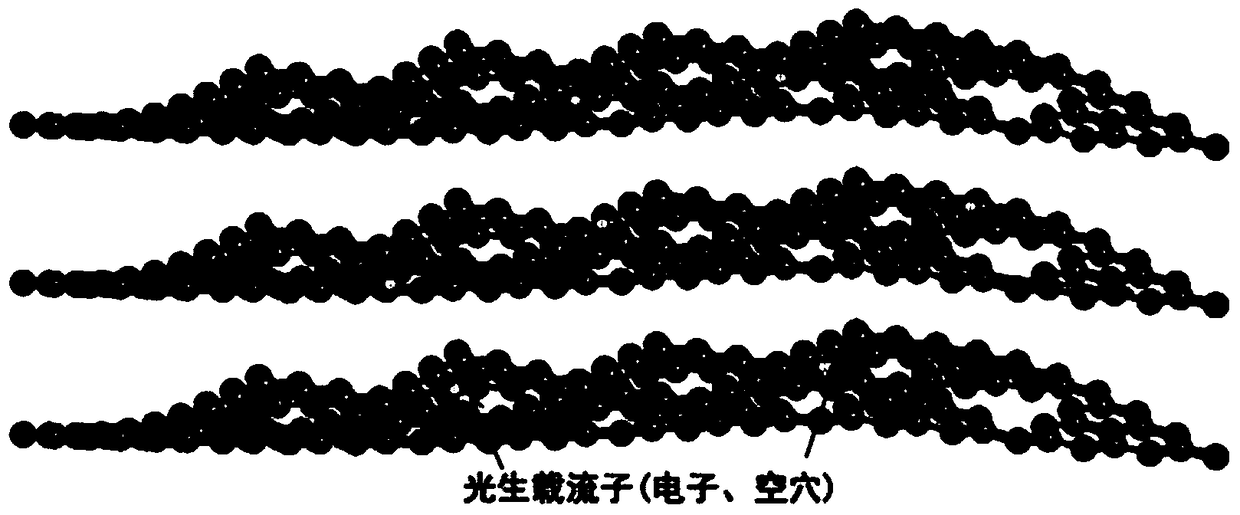

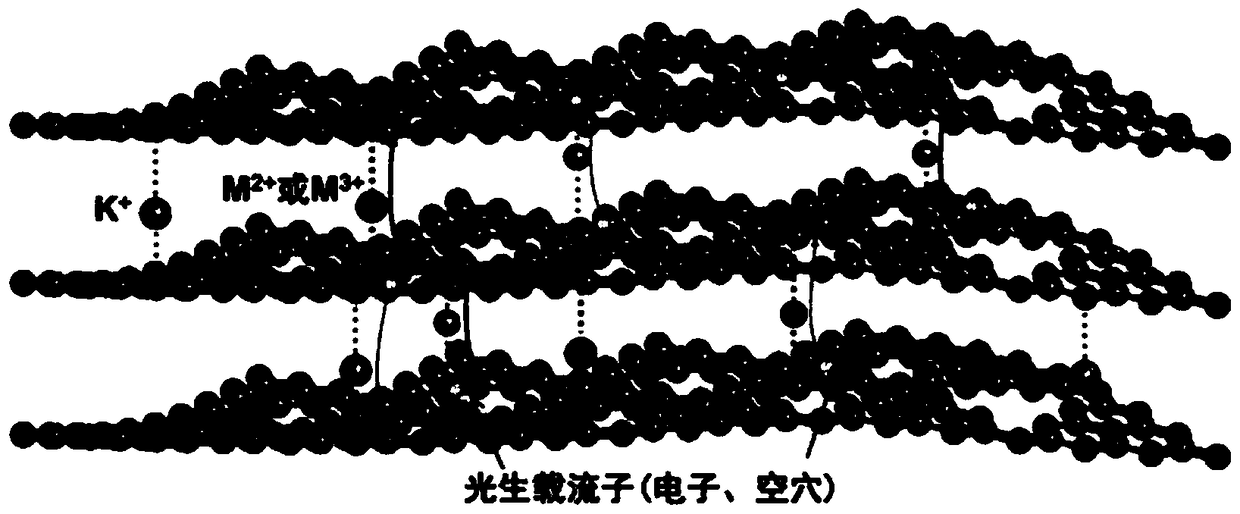

Interlayer double metal ion doped carbon nitride photocatalytic material and its preparation and application

An ion-doping and catalytic material technology, applied in the field of preparation and application of layered photocatalytic materials, can solve the problems of low quantum efficiency and high exciton binding energy, achieve high specific surface area, simple synthesis process, and improve reaction activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of carbon nitride doped with interlayer double metal ions: Disperse 1.5g of melamine in 30ml of ethanol, add 0.5ml of FeCl with a concentration of 0.5g / 10ml to it 3 ·6H 2 O in ethanol and evaporated to dryness at 80°C. Add 7.5g potassium chloride to the evaporated matter, put the mixed powder in a mortar and grind for 10-30min. After fully mixing evenly, put the powder in the crucible, seal the mouth of the crucible with aluminum foil paper, put it in a muffle furnace and raise the temperature to 550°C (the heating rate is 2.5°C / min), keep it warm for 4h, then cool to room temperature and take it out. The sintered powder is finely ground with a mortar, washed with deionized water and separated by suction filtration, dried at 80°C, and ground to obtain the interlayer K + , Fe 3+ Double-ion doped carbon nitride. Determined by X-ray photoelectron spectroscopy, K + The doping amount is 9.2% mole percent, Fe 3+ The doping amount is 1.7% by mole.

Embodiment 2

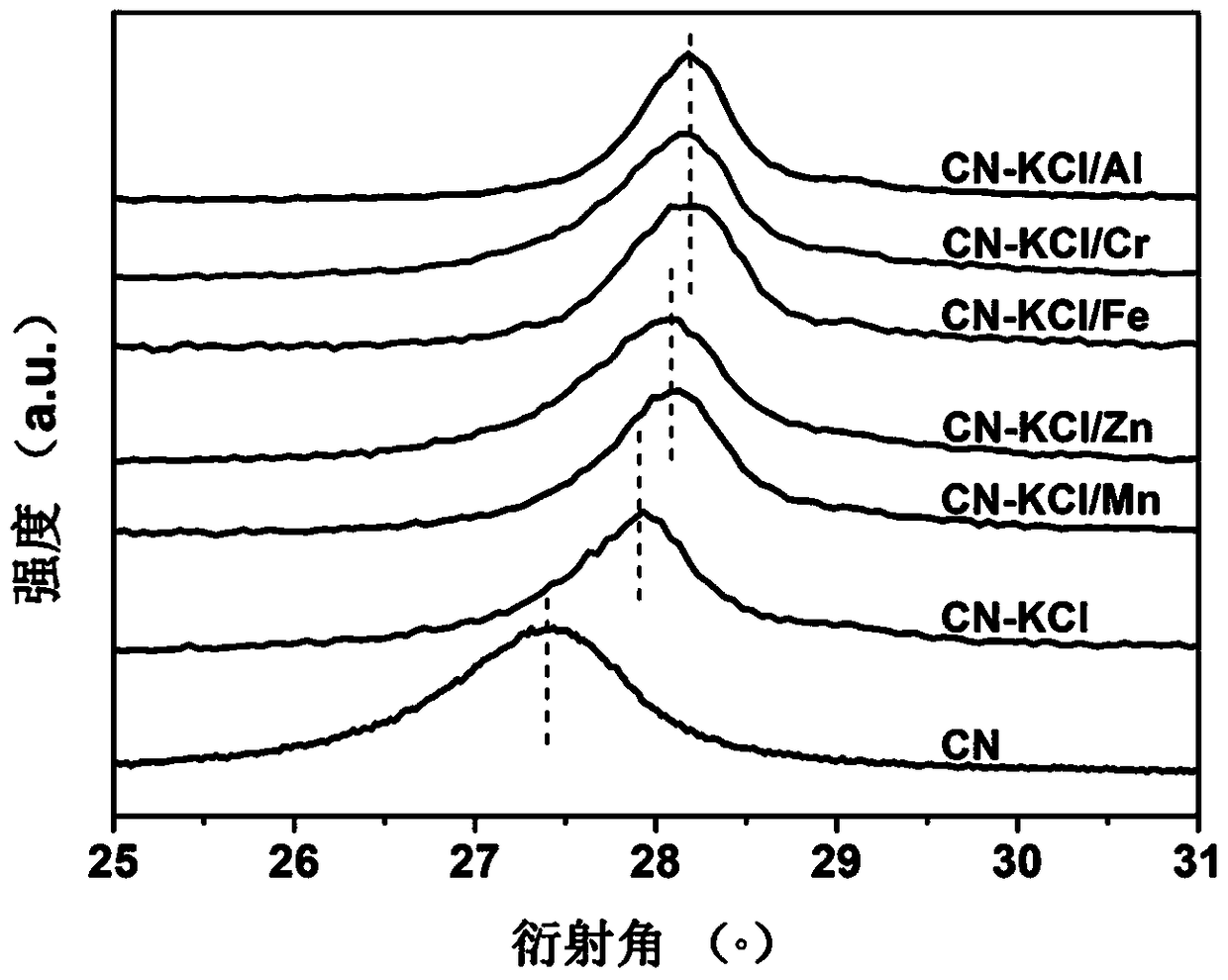

[0034] The influence of different doping elements on the product: Weigh 10 parts of 1.5g melamine, disperse them in 30ml ethanol respectively, add different volumes of FeCl with a concentration of 0.5g / 10mL to each of the ten samples 3 ·6H 2 O, Ga(NO 3 ) 3 , Cr(NO 3 ) 3 9H 2 O, AlCl 3 、CoCl 2·6H 2 O, MnCl 2 4H 2 O, ZnCl 2 , CaCl 2 , MgCl 2 ethanol solution and 0.5g / 10mL of BaCl 2 , SrCl 2 The aqueous solution was evaporated to dryness at 80°C. Mix the evaporated product above with 7.5g potassium chloride, and grind it in a mortar for 10-30min. After fully mixing evenly, put the powder in the crucible, seal the mouth of the crucible with aluminum foil paper, put it in a muffle furnace and raise the temperature to 550°C (the heating rate is 2.5°C / min), keep it warm for 4h, then cool to room temperature and take it out. The sintered powder was finely ground with a mortar, washed with deionized water and separated by suction filtration, dried at 80°C, and powdered ...

Embodiment 3

[0037] The influence of different carbon and nitrogen sources on the product: Weigh six parts of 1.5g of cyanamide, dicyandiamide, melamine, cyanuric acid, thiourea, and urea, and disperse them in 30ml of ethanol, and add 0.25ml of them to the concentration of 0.5 g / 10ml FeCl 3 ·6H 2 O in ethanol and evaporated to dryness at 80°C. Mix the evaporated product above with 7.5g potassium chloride, and grind it in a mortar for 10-30min. After fully mixing evenly, put the powder in the crucible, seal the mouth of the crucible with aluminum foil paper, put it in a muffle furnace and raise the temperature to 550°C (the heating rate is 2.5°C / min), keep it warm for 4h, then cool to room temperature and take it out. The sintered powder was finely ground with a mortar, washed with deionized water and separated by suction filtration, dried at 80°C, and powdered samples were obtained after grinding. Determined by X-ray photoelectron spectroscopy, K + The doping amount is 7-11% mole perce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com