Two-stage combined magnetic iron removing device

A magnetic and iron box technology, applied in magnetic separation, clay preparation device, solid separation, etc., can solve the problems of low degree of automation and work efficiency, high manual labor intensity, low iron removal efficiency, etc., to reduce labor intensity and improve Effect of iron removal quality and reliability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

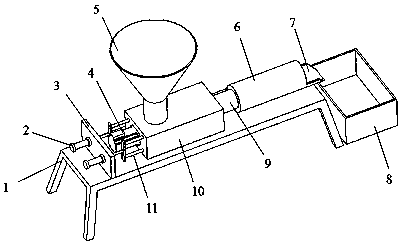

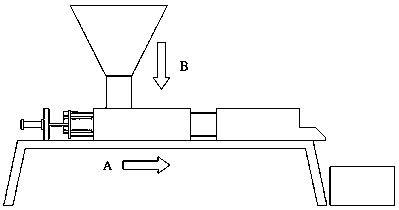

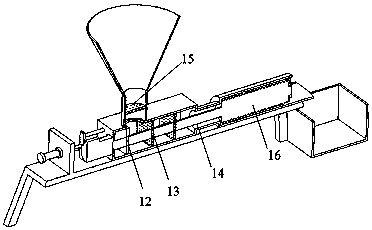

[0016] Such as Figure 1 to Figure 3 As shown, before the device works, the iron removal motor 4 does not start, and the piston rod of the push plate cylinder 2 is in the retracted state, so the push plate 12 is located on the left side of the iron removal box 10, and this state is the initial state before the device works.

[0017] After the preparatory work is completed, the slurry to be iron-removed is added from the top of the hopper 5, and after the relatively coarse sand particles are removed through the filter screen 15, the slurry flows into the iron-removing box 10. After the mud in the iron-removing box 10 reaches the specified liquid level, The push plate cylinder 2 moves, and the piston rod of the push plate cylinder 2 pushes the push plate 12 to move to the left side of the iron removal box 10. Under the extrusion force of the push plate 12, the iron is removed when the mud passes through the filter plate 13. When the mud passes through After the transition ring 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com