Semi-automatic clamp loading machine

A semi-automatic, clip technology, used in assembly machines, metal processing, metal processing equipment, etc., can solve problems such as inability to meet mass production of products, low assembly efficiency, and waste of labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

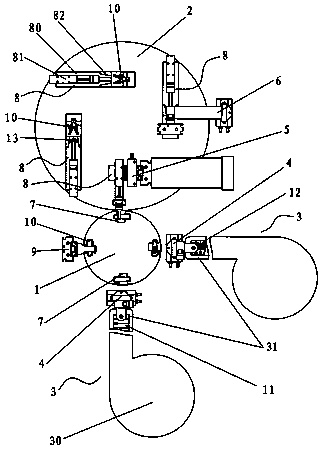

[0011] The present invention will be further described below in conjunction with accompanying drawing, see attached drawing figure 1 , a semi-automatic clamping machine, which includes a first turntable 1, a second turntable 2 adjacent to the first turntable 1, two feeding systems 3, two first manipulators 4, a linear cylinder 9, at least 4 along the first turntable 1 press-fitting jig 7 evenly distributed in the circumferential direction, at least 4 assembly jigs 8 evenly distributed along the circumferential direction of the second turntable 2, the second manipulator 5, the third manipulator 6, and the drive to rotate the first turntable 1 and the second turntable 2 The power unit, the second manipulator 5, the linear cylinder 9 and the two first manipulators 4 are sequentially arranged beside the first turntable 1 and correspond to the pressing fixtures 7 one by one, the feeding system 3 is set correspondingly to the first manipulator 4, and the second The manipulator 5 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com