Automatic assembling machine for photovoltaic connection wiring harness

A technology for connecting wire harnesses and assembling machines, which is applied in the field of automatic assembly machines for photovoltaic connecting wire harnesses, which can solve problems such as high labor intensity, inability to reduce labor costs, and low production efficiency, so as to reduce labor costs, improve space utilization, and increase labor productivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

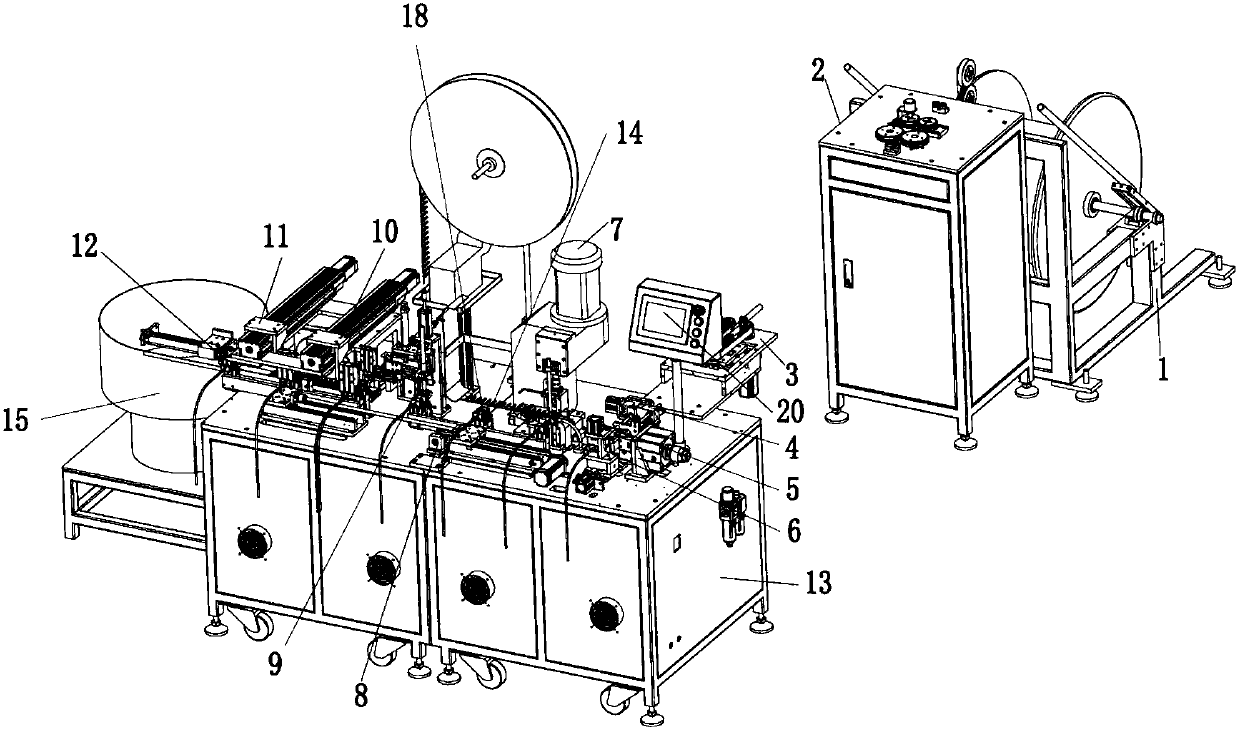

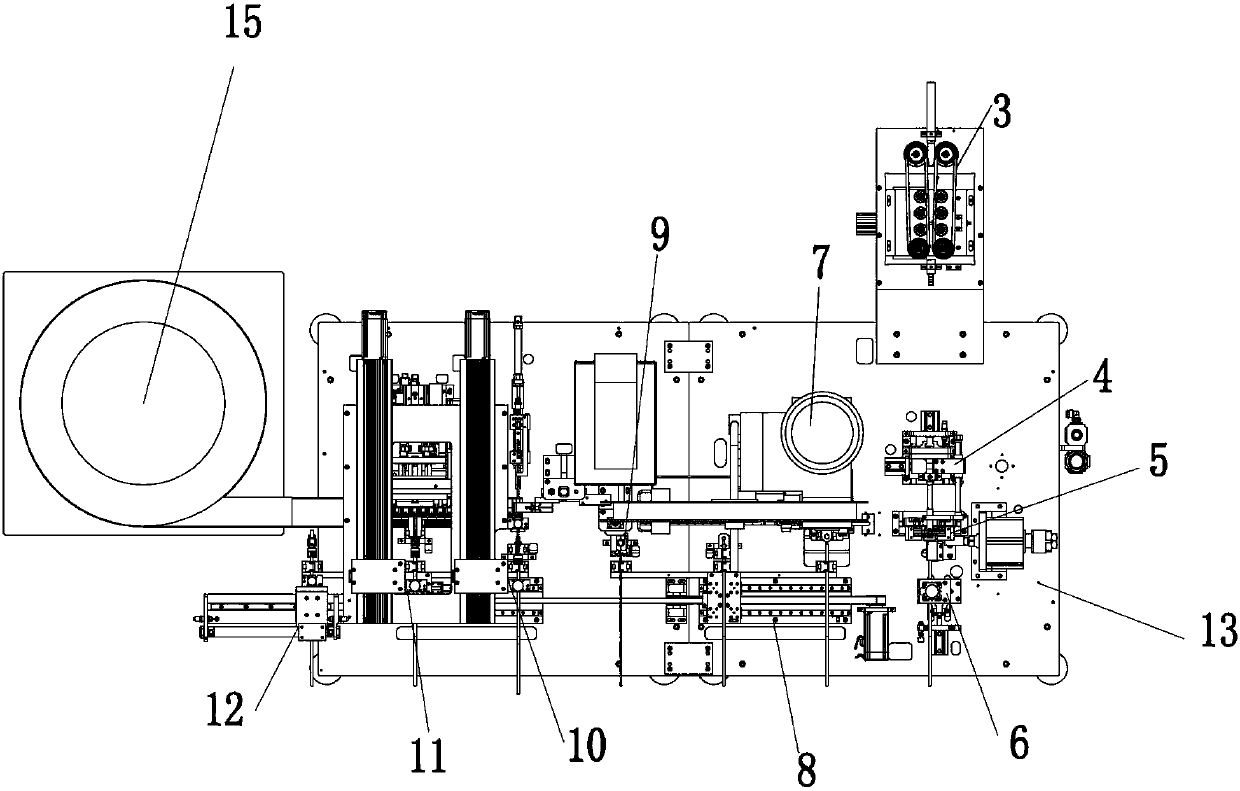

[0047] Such as Figure 1-Figure 15 As shown, the photovoltaic connection harness automatic assembly machine described in this embodiment includes a pay-off rack 1, an auxiliary mechanism 2, a wire feeding mechanism 3, a wire cutting and stripping mechanism 5, a front crimping mechanism 4, a rear crimping mechanism 6, a translation Mechanism 8, six wire taking mechanisms 81, riveting mechanism 7, terminal detection mechanism 19, solder mechanism 9, connector insertion mechanism 10, nut screwing mechanism 11, finished product removal mechanism 12, PLC controller, touch screen 20 and frame 13 .

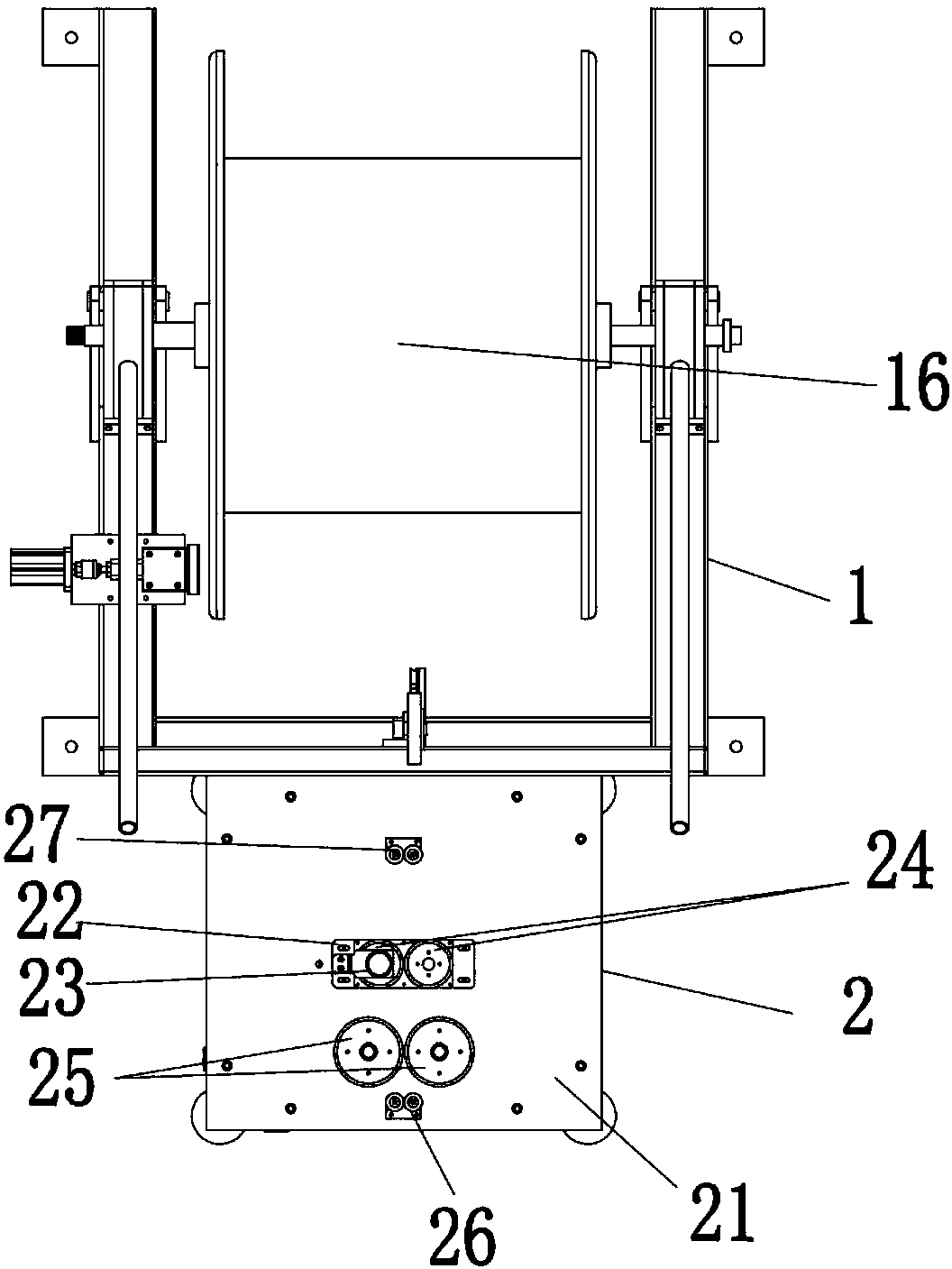

[0048] Pay-off rack 1: it is erected with a cable winding disc 16, and the cable winding disc 16 rotates on the pay-off rack 1 under the action of the bearing; An auxiliary lever 17 is also provided on the frame 1. Before the cable is released, the auxiliary lever 17 can be tilted on the ground, and the cable is pushed onto the pay-off frame 1 along the slope of the auxiliary lever 17. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com